Device and method for testing plane stress state of coal rock sheet under thermal-mechanical coupling condition

A thermal-mechanical coupling, test device technology, applied in the direction of applying stable tension/compression to test the strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] detailed description: According to the requirements of the experiment, there are two options for the size specification of the coal-rock thin plate specimen 8, namely: 200×200×20mm or 300×300×20mm. The test device can meet the thermal-mechanical coupling test requirements of the coal-rock thin plate test piece 8 under the plane stress state.

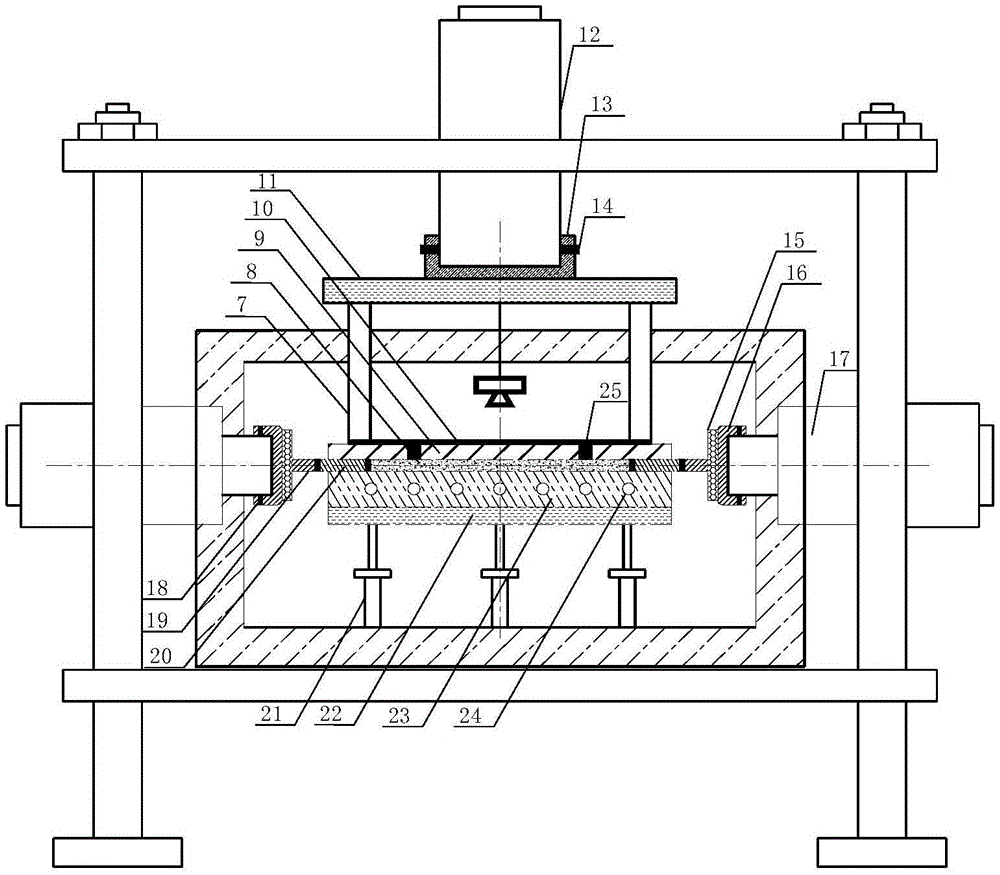

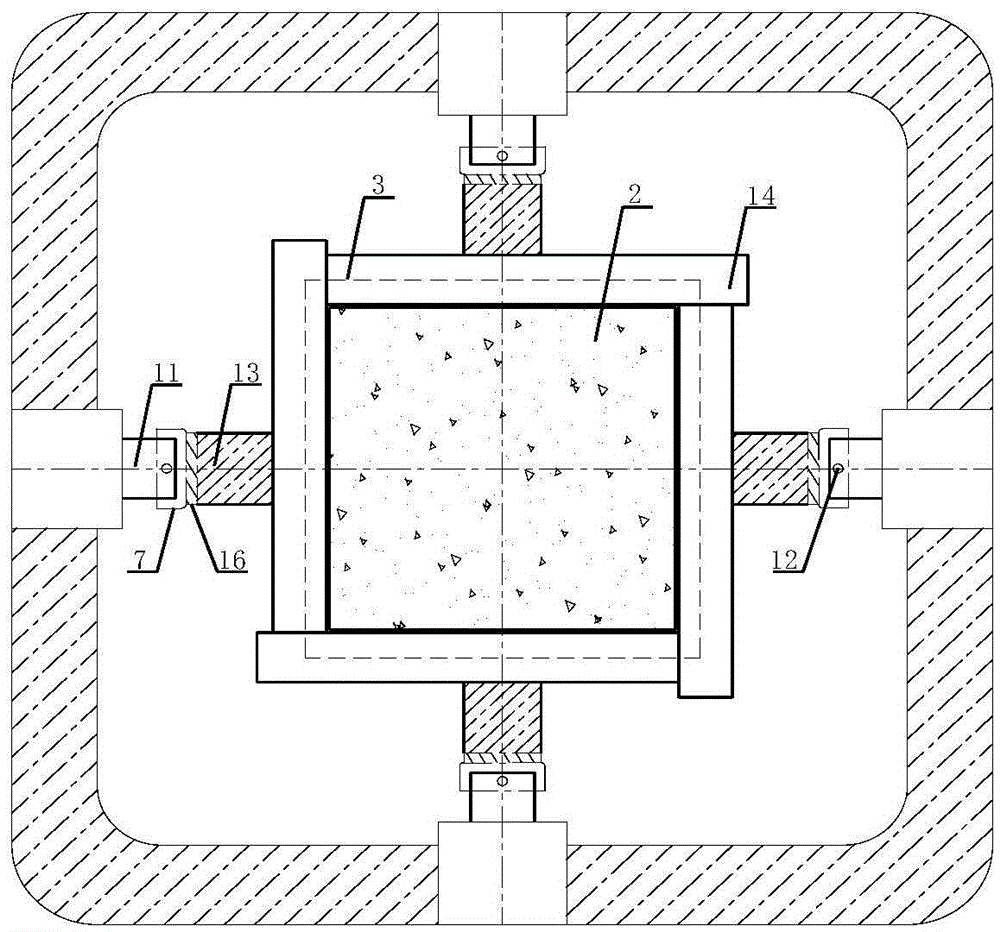

[0039] Axial strain restraint system 1 mainly provides longitudinal restraint for coal and rock thin plate specimen 8 to ensure that it is in a plane stress state; plane loading system 2 mainly provides plane stress load for coal and rock thin plate specimen 8; bottom temperature control and support adjustment The component system 3 mainly provides temperature control for the coal and rock thin plate test piece 8 and adjusts the balance of the supporting platform; the acoustic emission monitoring system 4 mainly uses the acoustic emission instrument to monitor the acoustic emission events of the coal and rock thin plate test piec...

Embodiment approach 1

[0041] In this implementation example, a 300×300×20mm coal rock thin plate specimen is taken as an example. Under the condition of a fixed temperature of 100°C, a thermal-mechanical coupling test under plane stress loading was carried out.

[0042] Adopting the experimental method of the coal rock thin plate plane stress state test device under the described thermomechanical coupling condition, comprises the following steps:

[0043] Step 1: Before the experiment, it is first required to adjust the support adjustment assembly at the bottom of the flat thin plate device to a horizontal state;

[0044] Step 2: Put the 300×300×20mm coal and rock thin plate test piece 8 into the pressure chamber, and apply low prestress to the test piece in both directions to fasten the test piece at the same time, and at the same time pass the axial high temperature and high pressure transparent The cover plate 9 imposes longitudinal displacement constraints on it;

[0045] Step 3: Connect each m...

Embodiment approach 2

[0049] In this implementation example, a 200×200×20mm coal rock thin plate specimen is taken as an example. Under the condition of fixed plane stress, respectively 3MPa and 5MPa, temperature loading thermomechanical coupling test, the temperature loading gradient is 20°C, keep the constant temperature for 15 minutes and then raise the temperature to the next gradient.

[0050] Adopting the experimental method of the coal rock thin plate plane stress state test device under the described thermomechanical coupling condition, comprises the following steps:

[0051] Step 1: Before the experiment, it is first required to adjust the support adjustment assembly at the bottom of the flat thin plate device to a horizontal state;

[0052] Step 2: Put the 200×200×20mm coal and rock thin plate test piece 8 into the pressure chamber, and apply low prestress to the test piece in both directions to fasten the test piece at the same time, and at the same time pass the axial high temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com