Testing circuit and testing method for temperature rise of IGBT module of frequency converter

A test circuit and frequency converter technology, applied in the power test of frequency converter IGBT devices and the temperature rise test circuit of frequency converter IGBT modules, can solve the problems of high power loss, limited test equipment, long test time, etc. Short time, reduced test cost, scientific effect of test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

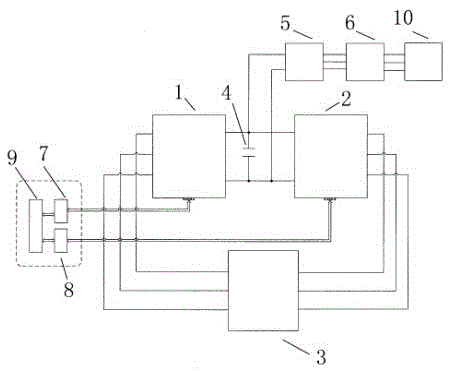

[0016] Principle of the present invention is described in detail as follows in conjunction with accompanying drawing:

[0017] A test circuit for temperature rise of an inverter IGBT module, comprising a first group of tested IGBT modules 1, a second group of tested IGBT modules 2, a load reactor 3, a first interface circuit board 7, a second interface circuit board 8 and Industrial control machine 9, the DC side of the first group of tested IGBT modules 1 and the DC side of the second group of tested IGBT modules 2 are connected together, and are connected together with the external DC power supply through a common DC bus, the first group The inverter side of the tested IGBT module 1 and the inverter side of the second group of tested IGBT modules 2 are connected together through a common load reactor 3 to form a back-to-back topology. The power grid 10 is connected to the rectifier through the voltage regulator 6 The cabinets 5 are connected together, the voltage output posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com