Method for realizing upper and lower roller load balance control based on 6RA80 direct current speed regulator

A load balancing and control method technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of unbalanced load and incomplete synchronization of actual speed, etc., and achieve the effect of uniform output, fast response speed and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

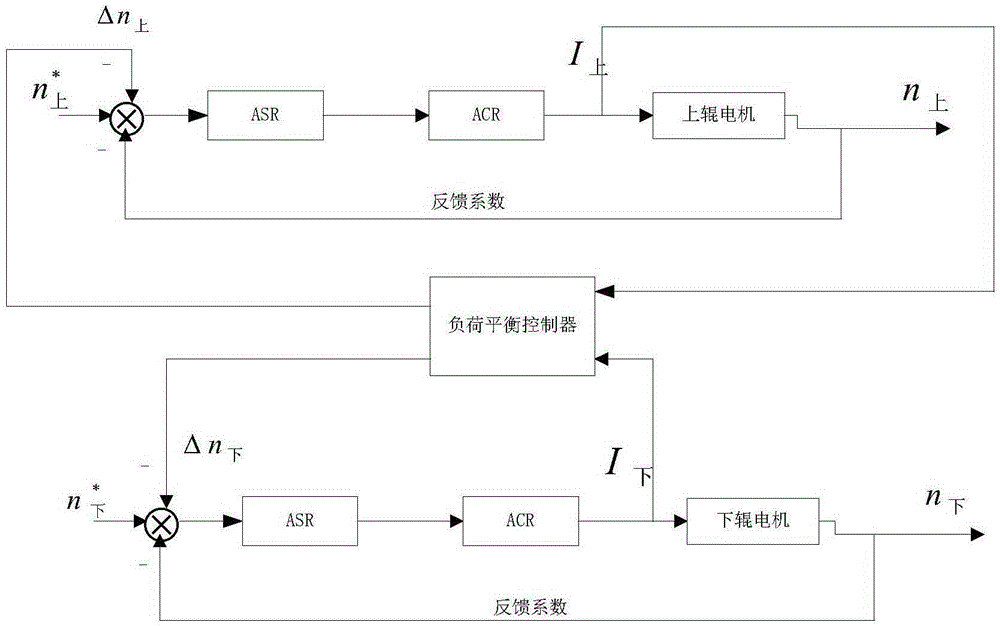

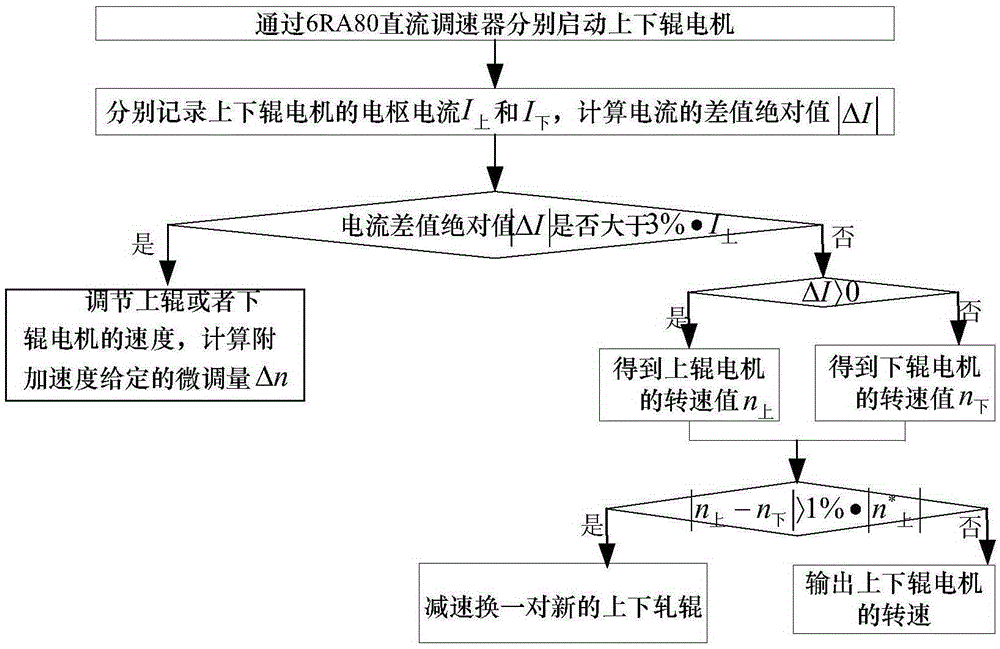

[0026] A method based on the DCC that comes with the 6RA80 DC speed controller to realize the load balance control method of the upper and lower rollers, based on the load balance control model, such as figure 1 As shown, the model includes: load balance controller, upper roller motor, lower roller motor and 6RA80 DC speed regulating device; 6RA80 DC speed regulating device integrates current regulator ACR and speed regulator ASR.

[0027] The load balance controller is respectively connected to the upper roller motor and the lower roller motor. The upper roller motor and the lower roller motor are controlled by their own independent 6RA80 DC speed control device. The upper roller motor and the lower roller motor drive the upper and lower rollers respectively.

[0028] The schematic diagram of the load balancing control model is as follows: figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com