Dimensionless index based fault diagnosis method for rotating machinery

A technology for rotating machinery and fault diagnosis, which is applied in the field of data processing and can solve problems such as conflicting evidence bodies provided by sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

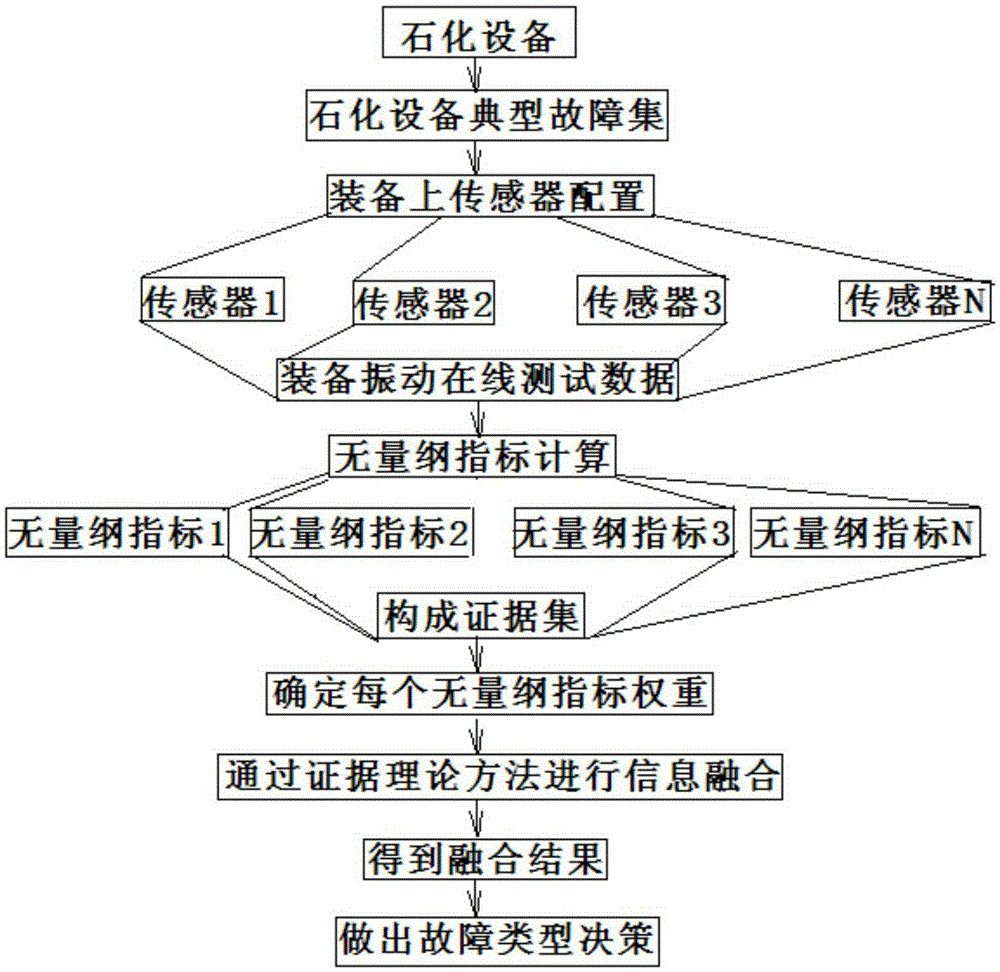

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0054] combine figure 1 It can be seen that a method for fault diagnosis of rotating machinery based on dimensionless indicators of the present invention comprises the following steps:

[0055] (1) Collect fault type signal data in real time from the sensors of the petrochemical rotating unit; the fault type signal data includes: bearing wear data, bearing external crack data, bearing internal crack data, bent shaft data, and missing bearing data.

[0056] (2) Carry out dimensionless index calculation on the collected signal data to obtain the waveform index S f , peak index C f , pulse index I f , margin index CL f and the kurtosis index K v ;

[0057] (3) Sampling the data obtained in (2) to obtain 1024 sample values to form a data set;

[0058] (4) Use the Kolmogorov-Smirnov test method; randomly select a sample value in the data set in (3) as the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com