Steel mesh image registration and detection method for large-format optical measurement system

An optical measurement system and image registration technology, applied in the field of image processing, can solve the problems of low accuracy and difficulty in registration and detection, and achieve good registration, reduce difficulty, and reduce the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] Such as Figure 8 As shown, the stencil image registration and detection method of a large-format optical measurement system of the present invention is realized by the following steps:

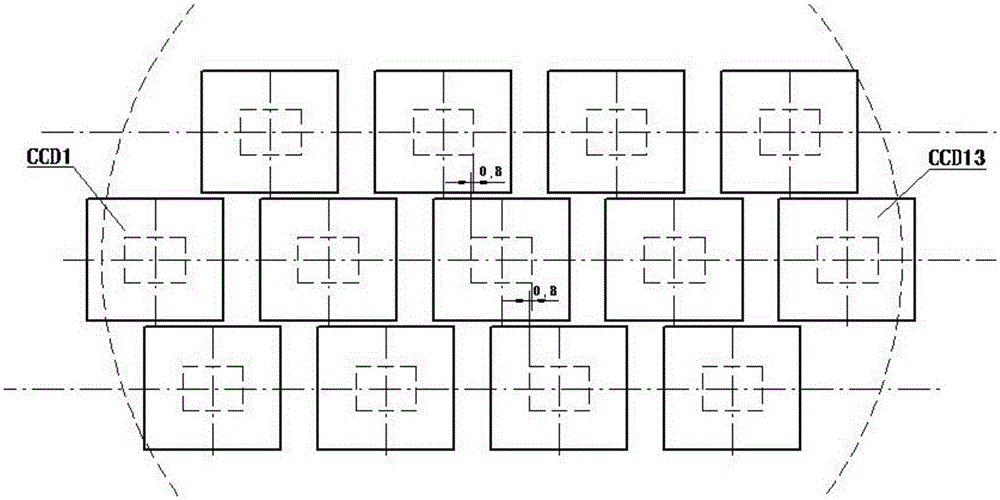

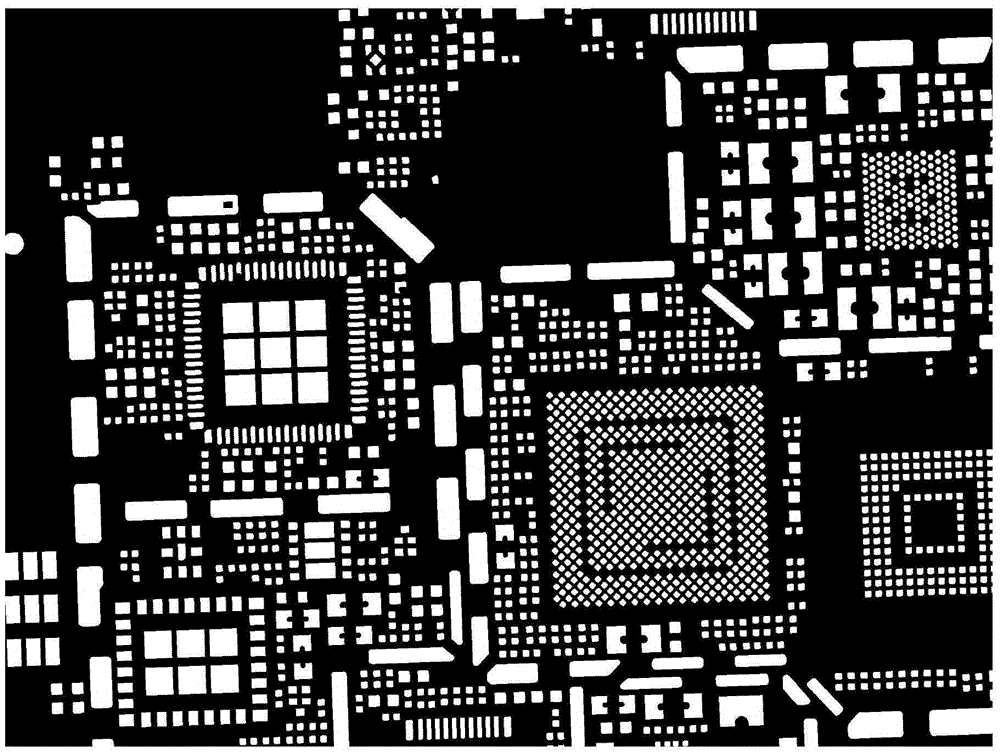

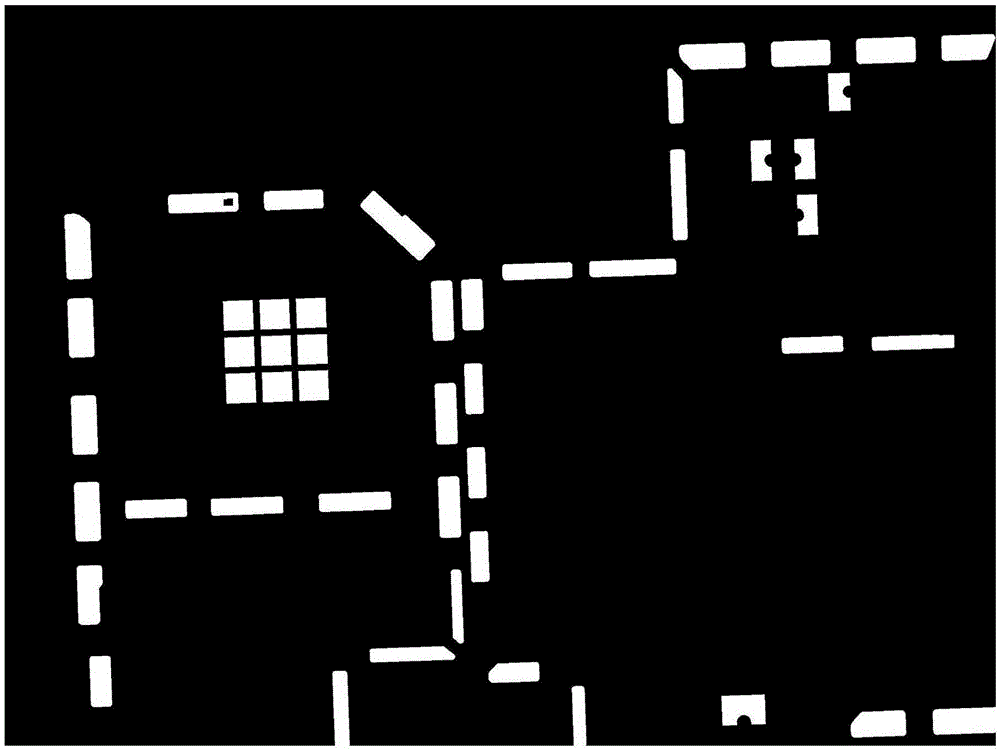

[0038] Step 1. According to the design parameters of the optical measurement system and the standard file of the stencil, determine the prior information of the image registration and detection: the vector file of the full-field stencil image, and the maximum stencil size is 900mm×800mm; take the image Each pixel corresponds to a stencil area of 15μm×15μm, and the maximum inclination angle of the stencil is θ=3°; 13 pieces of CMOS are in accordance with figure 1The shown product is arranged in a font, 13 pieces of CMOS horizontally, and 30 frames of vertical exposure can cover the full field of view, so it is necessary to divide the standard steel mesh file of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com