Base inspection device and method for FOUP (Front Opening Unified Pod)

A wafer transfer box and inspection device technology, which is used in optical device exploration, semiconductor/solid-state device testing/measurement, etc., can solve problems such as inability to lock threaded parts, handling equipment failure, and inconvenience, and reduce human inspection errors. The probability and the effect of saving the time of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

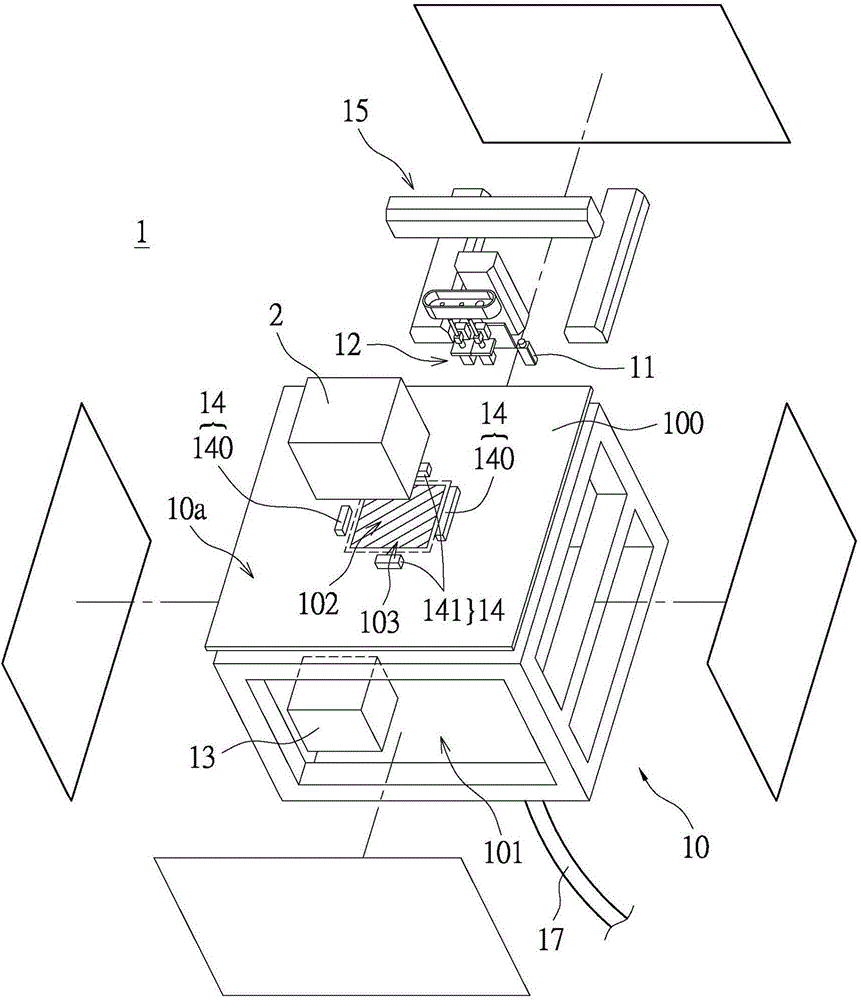

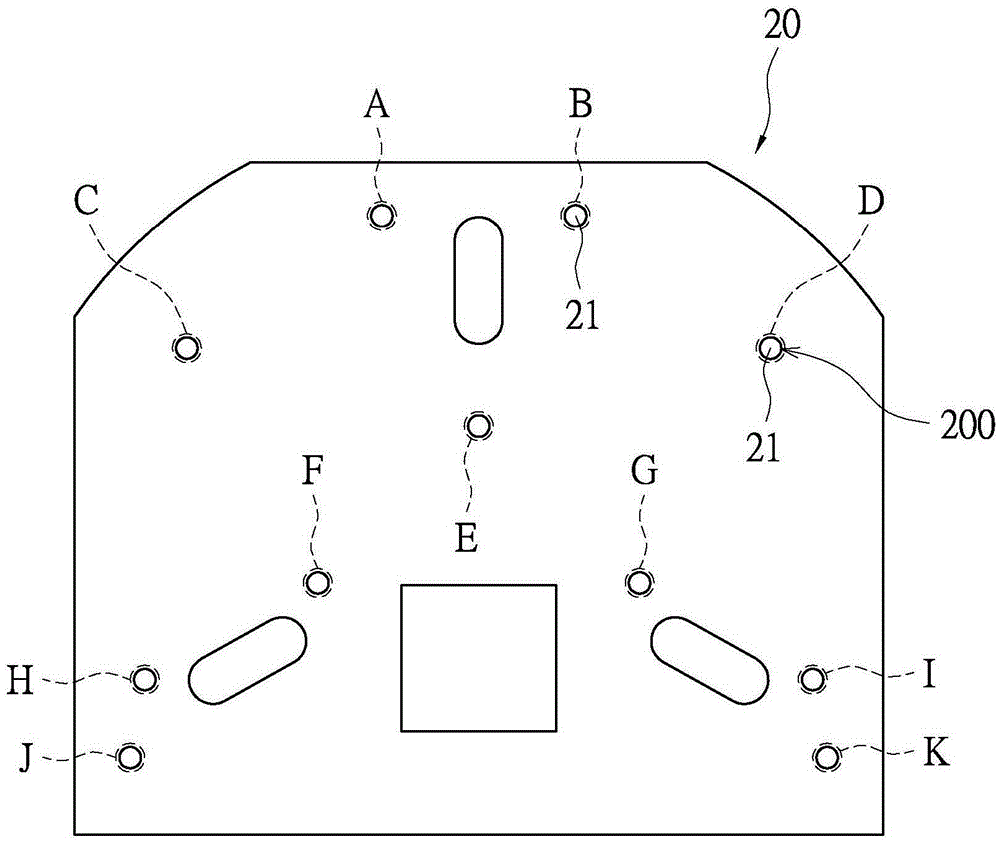

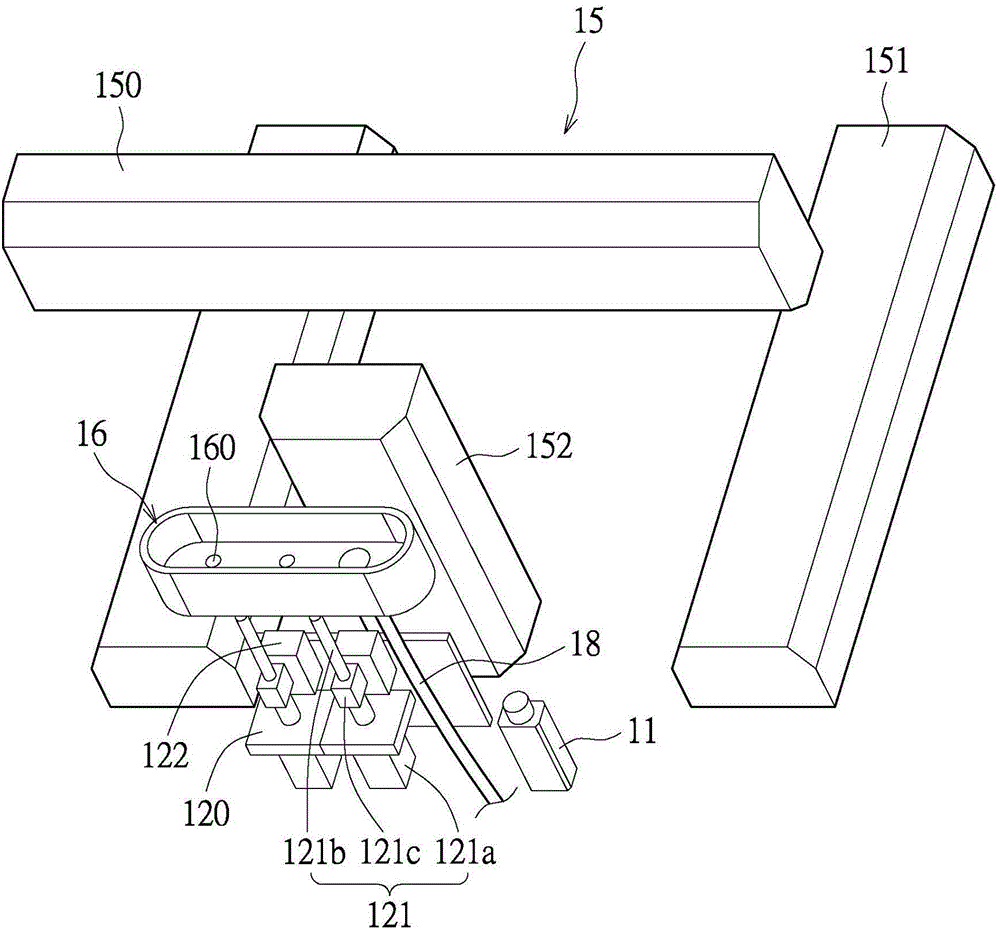

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Hereinafter, the present invention will be described in detail by illustrating embodiments of the invention with the accompanying drawings, and the same reference numerals in the drawings may be used to denote similar elements. The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the accompanying drawings.

[0053] The directional terms mentioned in the following embodiments, such as: "upper", "lower", "front", "rear", "left", "right", etc., are only referring to the directions of the accompanying drawings. Accordingly, the directional terms used are illustrative, not limiting, of the invention. Moreover, in the following embodiments, the same reference numerals are used to denote the same or si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com