Nickel cobalt lithium manganate positive electrode material and preparation method therefor

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the field of positive electrode materials and its preparation, can solve the problems of difficult uniform mixing, low stability of structure, composition, electrochemical performance, and slow solid phase diffusion speed, etc., and achieve excellent The effect of rate and cycle performance, good crystallization and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

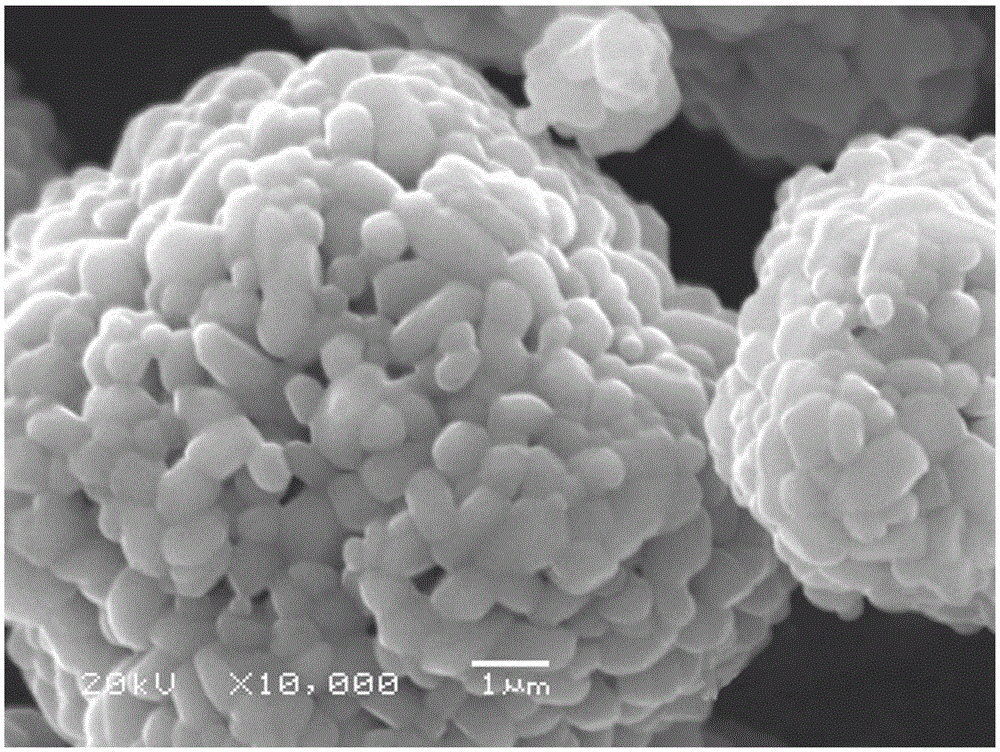

Embodiment 1

[0034] Prepare nickel cobalt lithium manganese oxide cathode material according to the following steps:

[0035] (1) Weigh 2kg of nickel-cobalt-manganese hydroxide, 1.1kg of lithium hydroxide monohydrate, and 3kg of deionized water into a 10L autoclave;

[0036] (2) Turn on the stirring, keep the stirring speed at 60 rpm, and the reaction temperature is 50°C, at 10m 3 Ozone with a concentration of 60mg / L is introduced at a flow rate of / h to cause the nickel-cobalt-manganese hydroxide to undergo an oxidation reaction, and the reaction time is 2h;

[0037] (3) Raise the reaction temperature of the autoclave to 200°C, control the pressure inside the autoclave at 3.0MPa, react for 1h, and form nickel-cobalt-lithium manganate precipitate, and cool to 40-50°C;

[0038] (4) Pour the nickel-cobalt-lithium-manganese oxide precipitate into a centrifuge for filtration, put the filtered material into a muffle furnace for sintering, the sintering temperature is 800°C, the sintering time ...

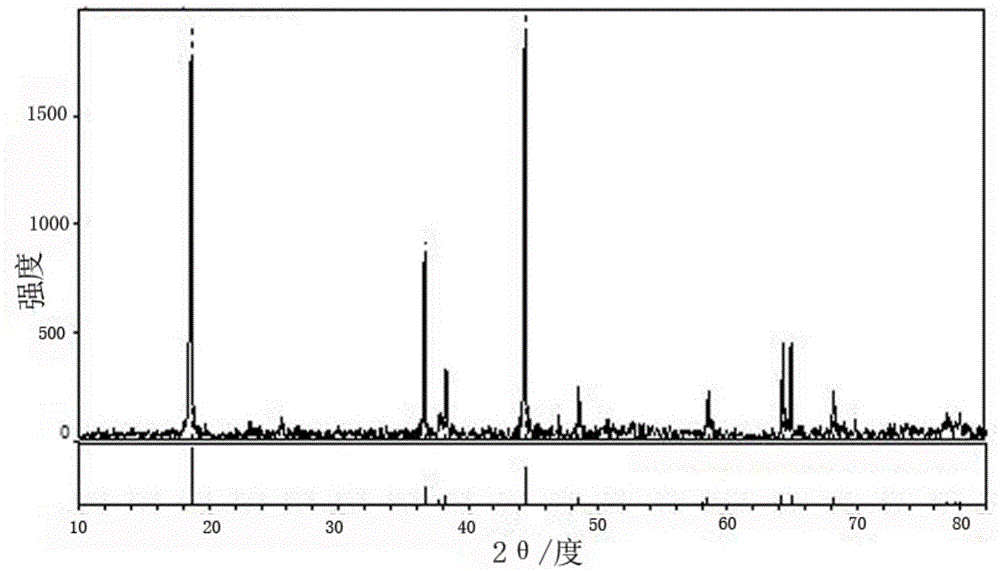

Embodiment 2

[0048] Prepare nickel cobalt lithium manganese oxide cathode material according to the following steps:

[0049] (1) Weigh 2kg of nickel-cobalt-manganese hydroxide, 1.1kg of lithium hydroxide monohydrate, and 3kg of deionized water into a 10L autoclave;

[0050] (2) Turn on the stirring, keep the stirring speed at 60 rpm, and the reaction temperature is 50°C, at 10m 3 Ozone with a concentration of 80mg / L is introduced at a flow rate of / h to make the nickel-cobalt-manganese hydroxide oxidize, and the reaction time is 2h;

[0051] (3) Raise the reaction temperature of the autoclave to 250 °C, control the pressure inside the autoclave at 5.0 MPa, react for 1 hour, and form nickel-cobalt lithium manganate precipitate, and cool to 40-50 °C;

[0052] (4) Pour the nickel-cobalt-lithium-manganese-oxide precipitation into a centrifuge to filter, put the filtered material into a muffle furnace for sintering, the sintering temperature is 850°C, the sintering time is 8h, and the sintere...

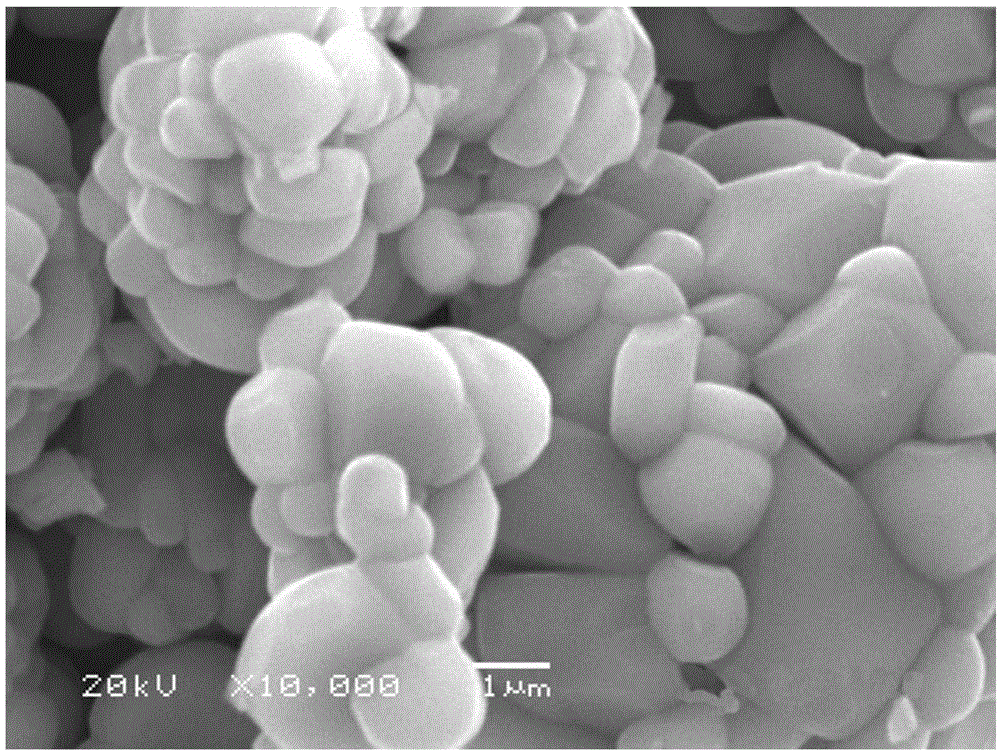

Embodiment 3

[0076] Prepare nickel cobalt lithium manganese oxide cathode material according to the following steps:

[0077] (1) Weigh 2kg of nickel-cobalt-manganese hydroxide, 0.5kg of lithium hydroxide monohydrate, and 2kg of deionized water into a 10L autoclave;

[0078] (2) Turn on the stirring, keep the stirring speed at 60 rpm, and the reaction temperature is 40°C, 3 Ozone with a concentration of 100mg / L is introduced at a flow rate of / h to cause the nickel-cobalt-manganese hydroxide to undergo an oxidation reaction, and the reaction time is 10h;

[0079] (3) Raise the reaction temperature of the autoclave to 150°C, control the pressure inside the autoclave at 0.2MPa, react for 5h, and form nickel-cobalt-lithium-manganate precipitate, and cool to 40-50°C;

[0080] (4) Pour the nickel-cobalt-lithium-manganese-oxide precipitate into a centrifuge for filtration, put the filtered material into a muffle furnace for sintering, the sintering temperature is 600°C, the sintering time is 15...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap