Multi-active zone epitaxial structure, semiconductor laser adopting same and manufacturing method of multi-active zone epitaxial structure

A technology of epitaxial structure and manufacturing method, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of increasing the far-field divergence angle of semiconductor lasers and deteriorating beam quality, so as to increase the burden of heat dissipation, reduce the diffraction effect, Effect of Reducing Power Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

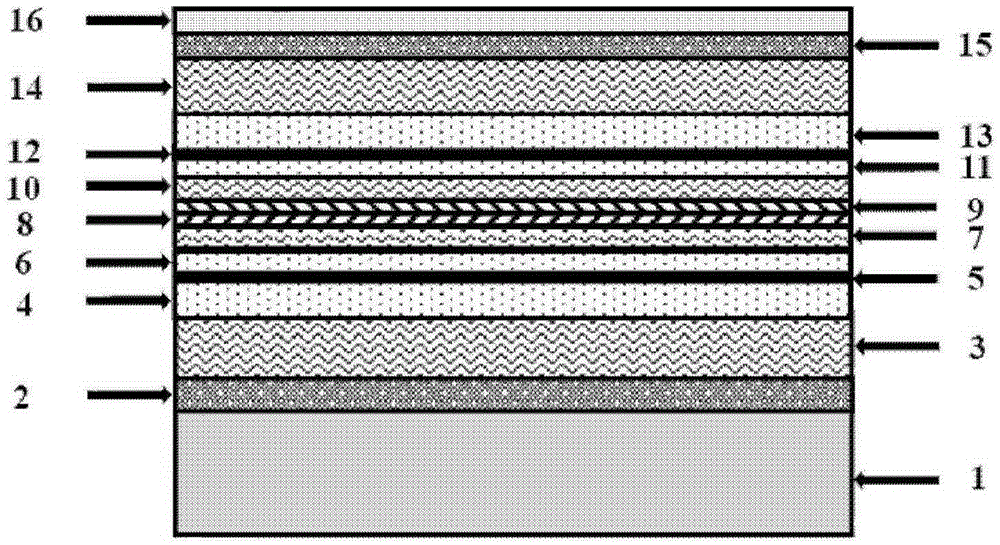

[0031] The invention discloses a tunnel cascade epitaxial structure with multiple active regions, comprising:

[0032] a substrate;

[0033] A plurality of active regions, the plurality of active regions are sequentially formed on the substrate, and the plurality of active regions are connected through a reverse-biased PN junction.

[0034] Wherein, in the reverse biased PN junction, the thickness of the P-type material is 10-20 nm, and the thickness of the N-type material is 10-20 nm.

[0035] Preferably, the reverse-biased PN junction is composed of a stacked P-type GaAs layer and an N-type GaAs layer.

[0036] Preferably, each of the plurality of active regions includes a lower confinement layer, a lower waveguide la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com