Compound, organic electroluminescence element material, ink composition, organic electroluminescence element, electronic device, and method for producing compound

一种化合物、键合的技术,应用在化合物领域,能够解决多种要求特性不充分等问题,达到高效简便制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

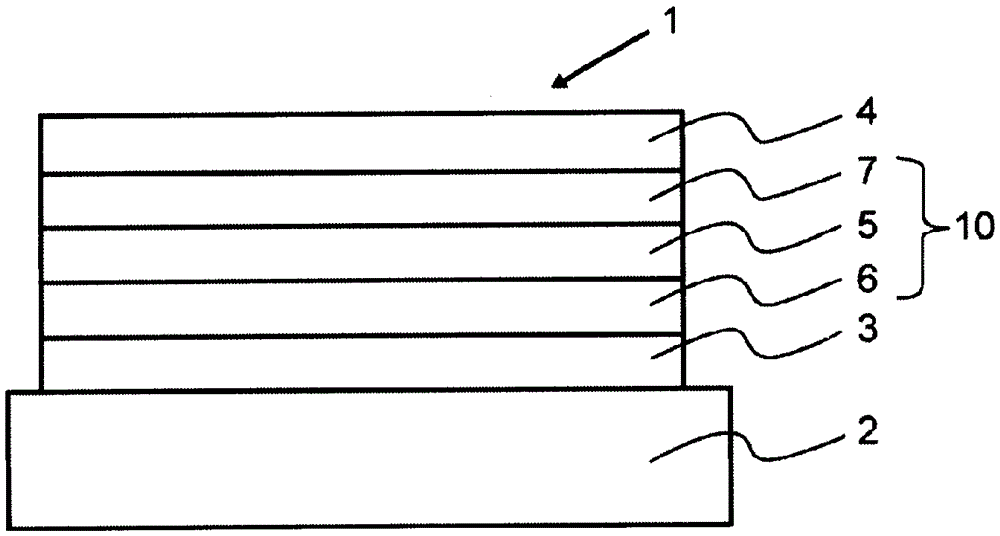

[1120] (Substrate washing)

[1121] A 25 mm x 25 mm x 1.1 mm thick glass substrate with an ITO transparent electrode (manufactured by Geomatec Co., Ltd.) was ultrasonically cleaned in isopropanol for 5 minutes, and then UV ozone was washed for 5 minutes.

[1122] (formation of basal layer)

[1123] On the above-mentioned ITO substrate, CLEVIOUS AI4083 (trade name) manufactured by HERAEUS Co., Ltd. as a hole transport material was formed into a film with a thickness of 30 nm by the spin coating method. After the film formation, unnecessary parts were removed with acetone, and then fired on a hot plate at 200° C. for 10 minutes in the air to produce a base substrate.

[1124] (Formation of luminescent layer)

[1125] Compound H-4 obtained in Synthesis Example 4 was used as a host material, and the following compound D-1 was used as a dopant material, and mixed so that the mass ratio of compound H-4: compound D-1 was 90:10 A mixing ratio of 1.6 mass % was prepared in toluene. ...

Embodiment 2

[1130] An organic EL device was produced in the same manner as in Example 1 except that Compound D-2 was used as a dopant material. The measurement results are shown in Table 1.

Embodiment 3

[1136] Using the compound H-13 obtained in Synthesis Example 13 as the host material and the following compound D-1 as the dopant material, the mixing ratio of compound H-13:compound D-1 reached 95:5 in terms of weight ratio An organic EL element was fabricated by the same method as in Example 1 except that a 1.6% by weight toluene solution was prepared. The measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com