Steel bridge framework installing and welding method

A frame and steel bridge technology, applied in the field of assembly and welding, can solve the problems of product quality decline, method difficulty, size change, etc., to achieve the effect of ensuring quality and construction period, ensuring quality, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings. However, embodiments of the present invention are not limited thereto.

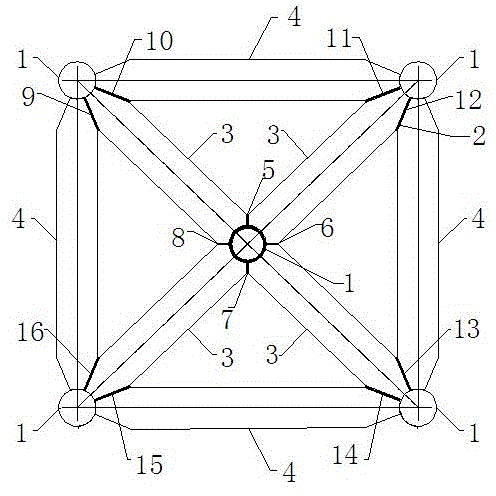

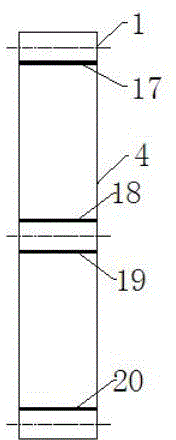

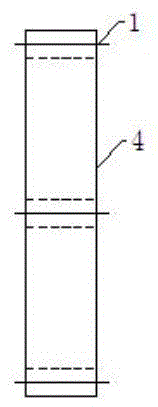

[0011] The material plates used in the assembly welding method are all made of Q345BH-shaped steel; on the workbench, 4 pieces of the first material plate 3 are reserved for a certain weld width and assembled on the outside of the steel pipe 1 at the same angle at the same interval. After the assembly is completed, use CO 2 Gas shielded welding is used to spot weld and fix the center of the connection between the four first material plates 3 and the steel pipe 1; after the spot welding is fixed, insert the reinforcing plate 2 at the weld between the adjacent first material plates 3, and use the reverse deformation method , two welders use CO 2 Gas shielded horizontal welding, simultaneous diagonal welding, welding seam 5 and welding seam 7 are diagonally welding at the same time, and welding seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com