Manufacturing equipment for glue dipped strips special for bamboo floor production

A technology for manufacturing equipment and dipping strips is applied in the field of manufacturing equipment for special dipping strips for bamboo floor production, which can solve the problems of impeding glue soaking, time-consuming and laborious, low efficiency, etc., so as to avoid the increase of processing costs and processing procedures. Guarantee the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

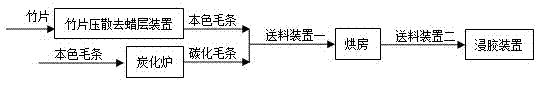

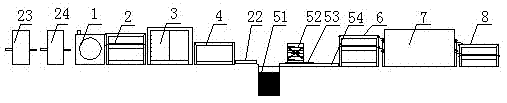

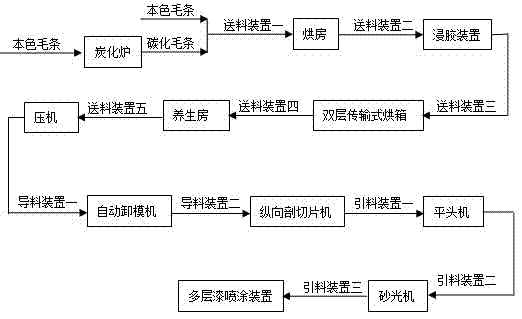

[0035] A kind of manufacturing equipment of bamboo floor production special dipping strip, such as figure 1 and figure 2, including a pressure-dispersed wax layer device, a carbonization furnace for the carbonization of natural wool tops 1, a double-layer feeding device 1 2, a drying room 3, a side-by-side feeding device 4, a dipping device 5, and a double-layer feeding device 2 6 , double-layer transmission oven 7, double-layer feeding device 3 8, double-layer feeding device 2 6 and double-layer feeding device 3 8 are respectively arranged at the feeding place and the discharge place of the double-layer conveying oven 7, and the double-layer conveying type Curved guide plates are respectively provided between the oven 7 and the double-layer feeding device 2 6, and the double-layer transmission oven 7 and the double-layer feeding device 3 8; The wax layer removal device includes a longitudinal pressure-dispersion wax-removal component 23 and a horizontal pressure-dispersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com