Indigo-blue jean dyeing machine

A technology for denim and dyeing machine, applied in dyeing method, textile and papermaking, liquid/gas/vapor removal with squeeze rollers, etc. It can solve the problems of long process flow, low efficiency and many labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

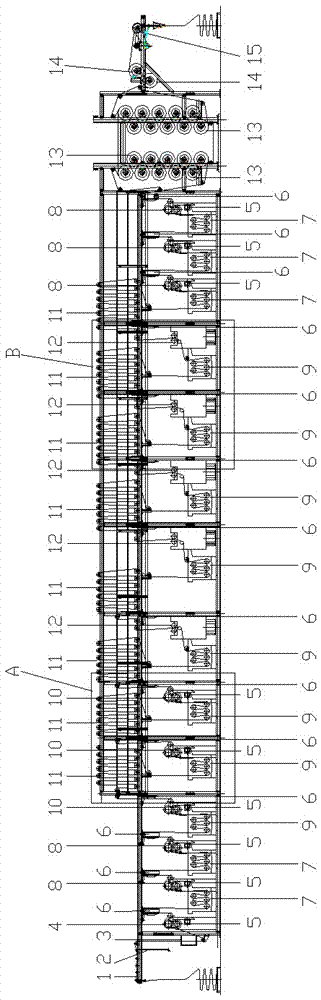

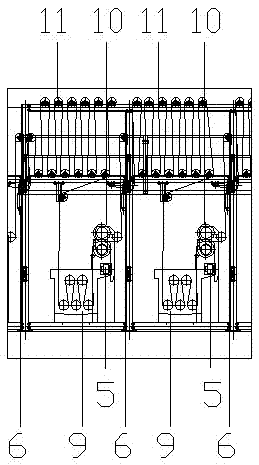

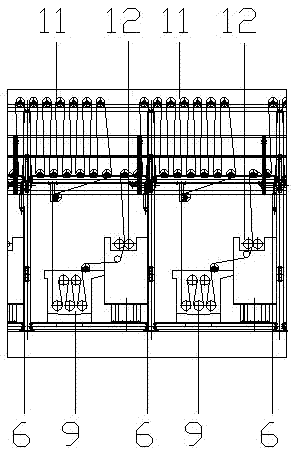

[0034] Embodiment: a kind of indigo denim dyeing machine.

[0035] Such as Figure 1 to Figure 3 As shown, an indigo denim dyeing machine includes a cloth feeding device 1, a gray cloth cleaning system, a cloth surface dyeing system, a colored cloth cleaning system, a cloth surface drying system, a cloth surface cooling system and a cloth output device 15. in:

[0036] The cloth feeding device includes a cloth surface pretensioner 2, a cloth surface centering device 3 and a two-roller cloth surface smoothing roll 4.

[0037] The gray cloth cleaning system includes two groups of cloth surface cleaning tanks 7 and two rollers of cloth surface rolling hydraulic pressure rollers 8 . Cloth cleaning tank 7 cleaning water capacity 2000L.

[0038] The cloth surface dyeing system is a continuous pad dyeing oxidation system and a level dyeing oxidation system, wherein the pad dyeing oxidation system is composed of three groups of cloth surface dyeing tanks 9, two rolls of dye liquor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com