Crescent-shaped dehydrating screen for paper making machine

A paper machine and crescent technology, which is applied in the field of dewatering wire for crescent paper machines, can solve the problems of inability to meet the needs of high-grade household paper production, low speed of the paper machine, poor softness, etc., and achieves strong water absorption, The effect of fast dehydration and clear oblique lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

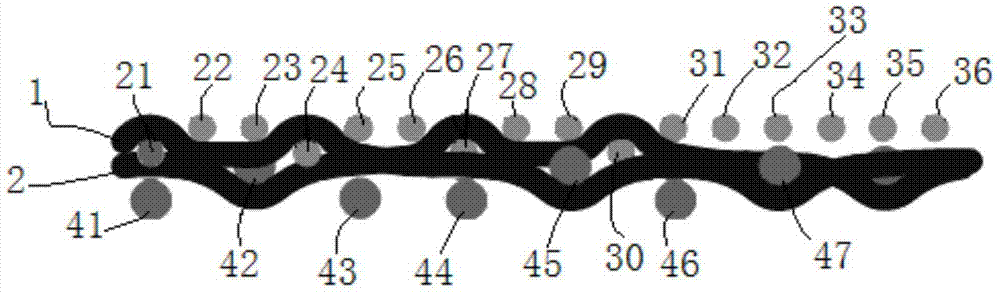

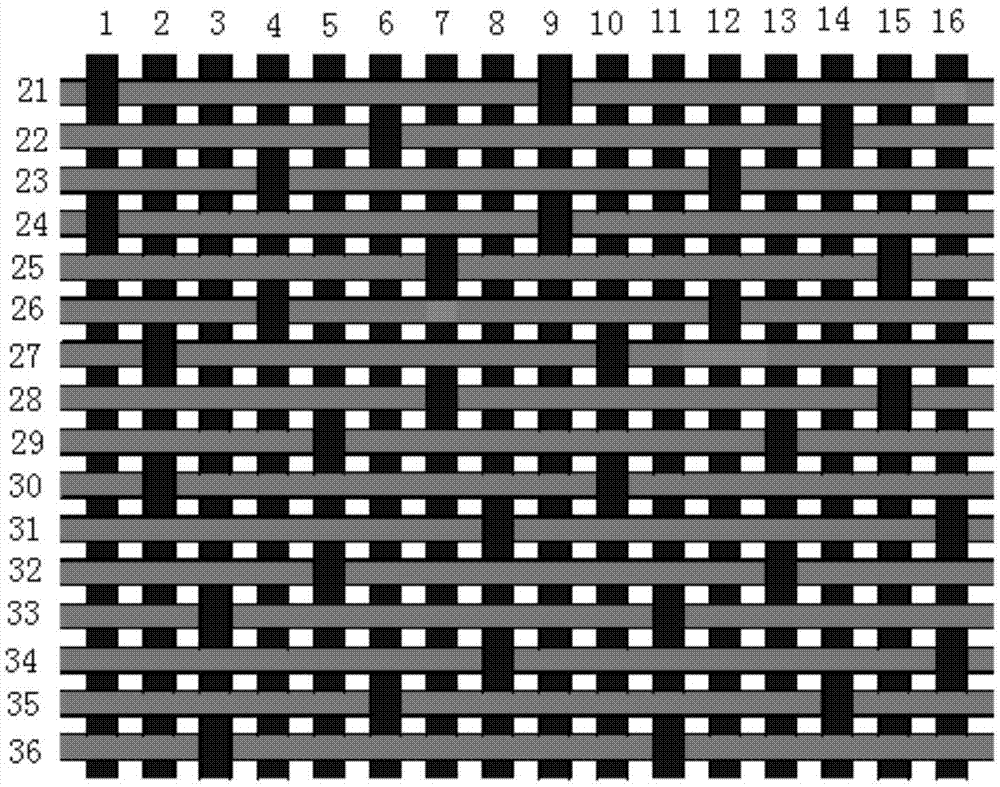

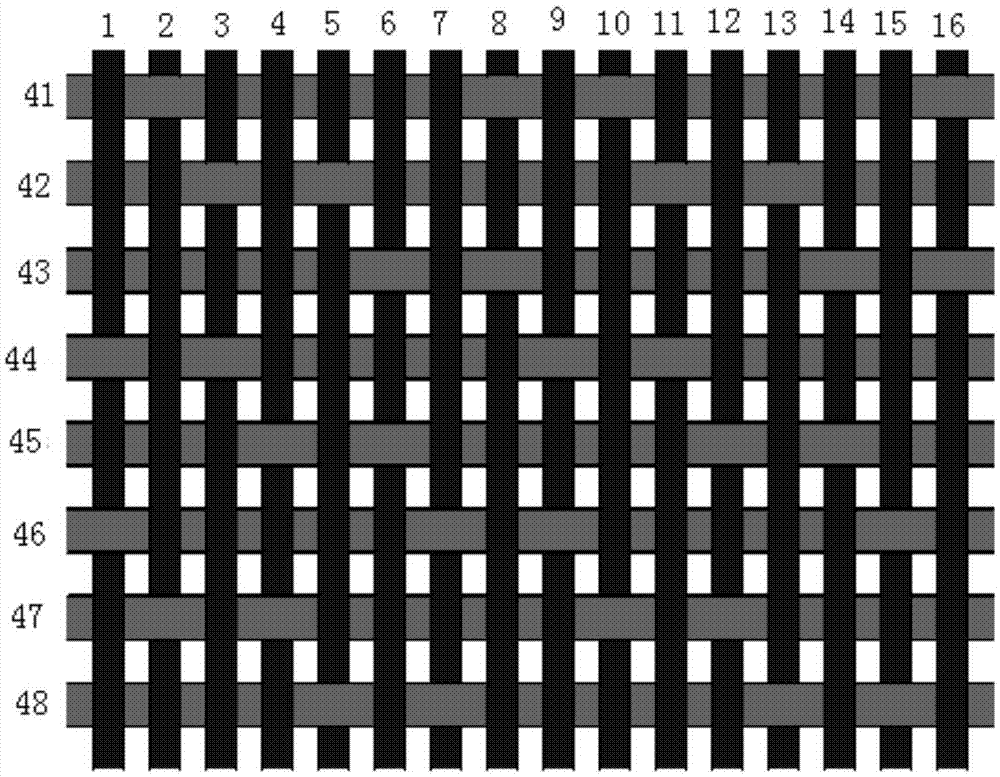

[0030] Such as figure 1 , figure 2 with image 3 Shown: 1-16 are 16 warp threads, 21-36 are 16 weft threads in the upper layer, and 41-48 are 8 weft threads in the lower layer.

[0031] Such as figure 1 Shown: 16 warp threads from 1 to 16 interweave with 16 weft threads from 21 to 36 to form the upper layer of the dehydration net, forming the front side of the dehydration net. The front side of the dehydration net forms oblique lines and weft satin weaves, and the protruding front weft supports fine fibers , high fiber retention rate, low basis weight and good formation.

[0032] Such as figure 2 Shown: 16 warp threads from 1 to 16 interweave with 8 weft threads from 41 to 48 to form the lower layer of the dewatering net, forming the reverse side of the dewatering net. .

[0033] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warp diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com