Connection structure of prefabricated bridge pier and bearing platform and construction method thereof

A bridge pier and structure technology is applied to the connection structure of prefabricated bridge piers and caps, and the installation and positioning technology of annular section prefabricated bridge piers and caps. Achieve the effect of speeding up construction progress, simple positioning of bridge piers, and enhancing shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

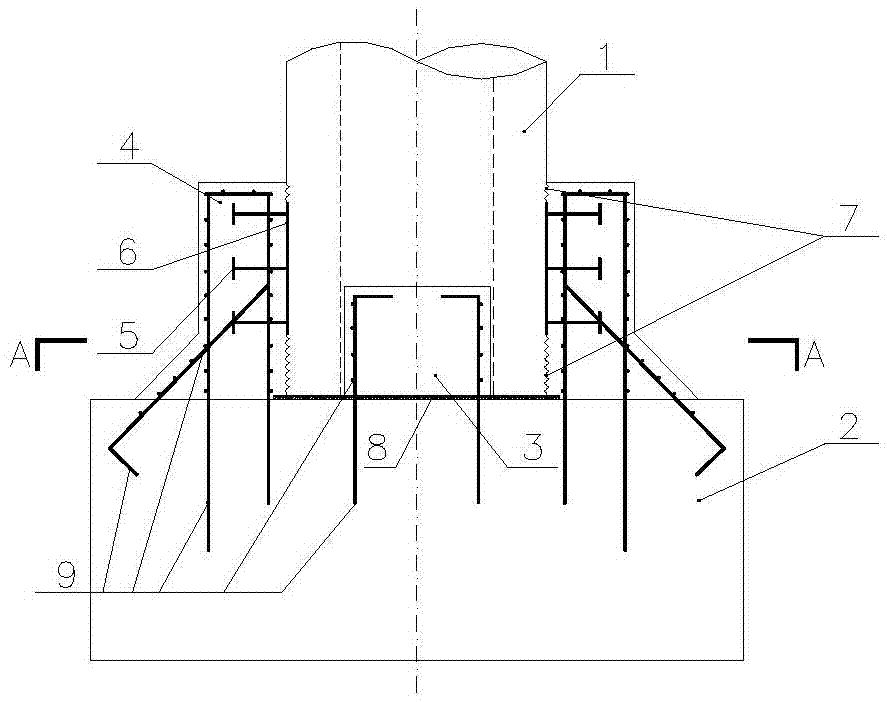

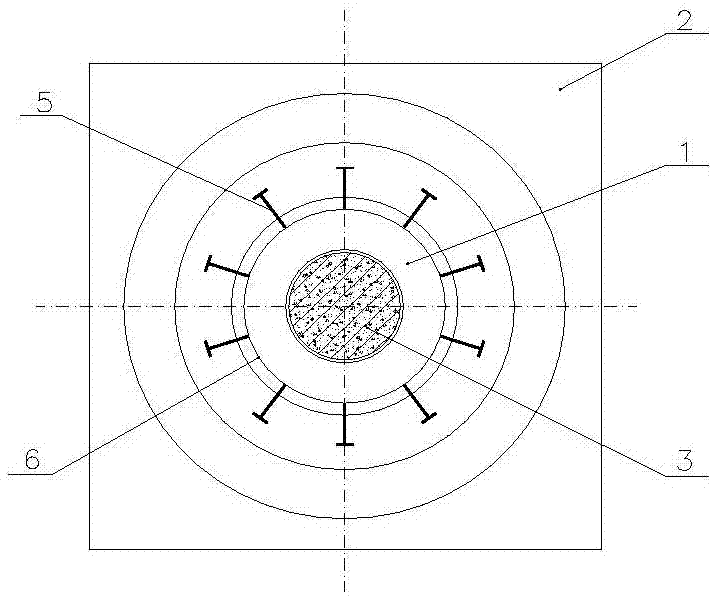

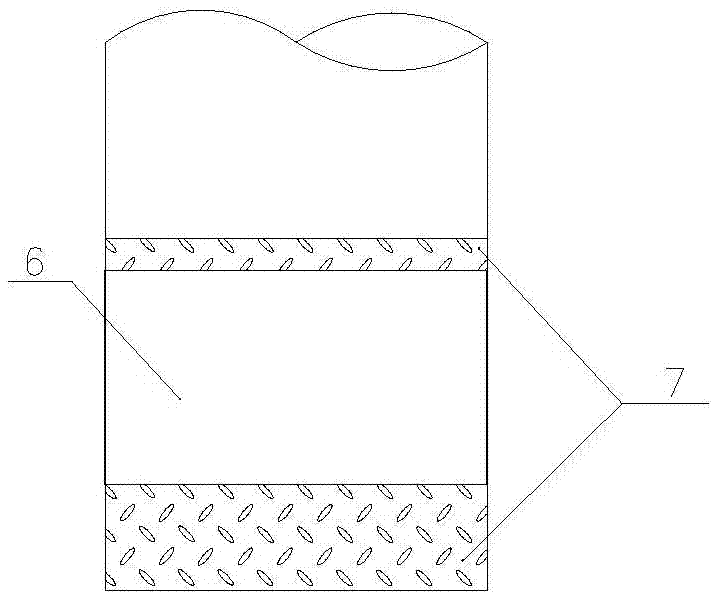

[0033] A connection structure for prefabricated bridge piers and caps. The prefabricated bridge piers with circular cross-section are set on the positioning piers 3 to complete the installation and positioning, and then the cup-mouth mounting island 4 is connected with the caps 2 through cast-in-place concrete to integrate them. The ring-shaped prefabricated bridge pier 1 is provided with an outer covering steel plate 6 and an embossed pattern cutting section 7 at the bottom of the pier. After installation and positioning, three layers of staggered shear nails are welded to the outer steel plate 6 to be used as the shear key 5, and finally the cup mouth installation island 4 is poured into the concrete connecting platform 2. A 2 cm thick mortar leveling layer 8 is provided between the positioning pier 3 and the bearing platform 2, and the positioning pier 3 and the bearing platform 2 are connected by a reserved steel bar 9.

[0034] Taking a single-pillar pier as an example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com