Application of positioning rib in large storage tank bearing platform ring wall foundation

A large-scale storage tank and positioning rib technology, which is applied in the field of invention and application, can solve the problems of excessive flatness of the surface of the surrounding wall, waste of construction period and construction cost, difficulty in finishing the surface of the surrounding wall, etc., so as to shorten the construction period, improve the flatness, reduce the The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

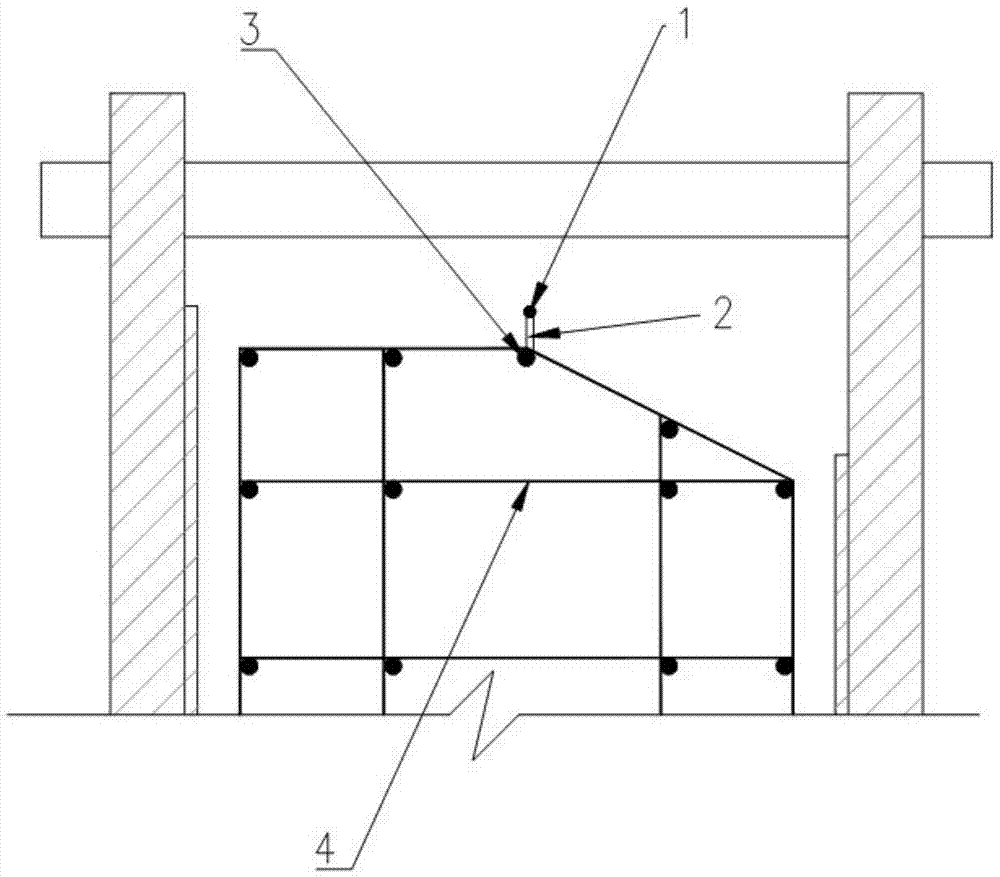

[0012] Such as figure 1 As shown, the inventive application of the positioning rib of the present invention in the foundation of the ring wall of the large-scale storage tank cap, the positioning rib is applied to the foundation of the ring wall of the large-scale storage tank cap, and the elevation of the positioning rib is the same as that of the ring wall foundation after forming Consistent, the positioning rib is an annular ring-shaped steel bar 1 arranged in the horizontal direction, the bottom end of the ring-shaped steel bar 1 is connected to the top of a plurality of vertical bars 2 by welding, and the adjacent vertical bars 2 The distance between them is 900-1100mm, and the bottom end of each vertical bar 2 is welded and connected with the main bar 3 arranged along the horizontal direction, and the main bar 3 is welded and fixed on the top of the reinforced grid frame 4 of the ring wall foundation of the storage tank cap.

[0013] As a further improvement of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com