Bypass type passive double-throat pneumatic vector spraying pipe with flow regulating function and control method

A flow regulation and vectoring nozzle technology, which is applied in engine functions, jet propulsion devices, machines/engines, etc., can solve the problems of cumbersome structure and complex thrust vectoring nozzle design, and achieve the effect of expanding the working range and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

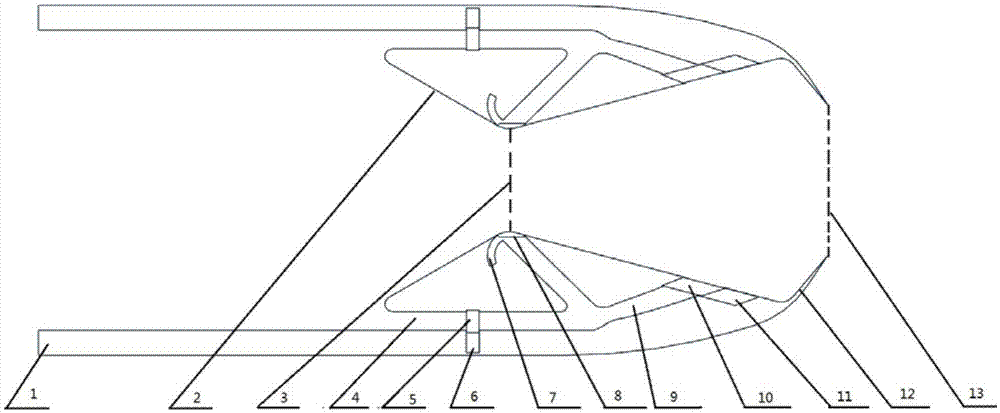

[0027] Such as figure 1 The shown invention is applied to the side view of the internal structure of the binary double-throat nozzle, and the structure has the following components: nozzle wall 1, a throat front converging section 2, a throat 3, bypass passage 4, Flow adjustment switch a5, switch guide rail 6 of flow adjustment switch a, flow adjustment switch b7, switch guide rail 8 of flow adjustment switch b, flow adjustment channel 9, flow adjustment switch c10, switch guide rail 11 of flow adjustment switch c, two throats The front part expands and converges section 12, two throats 13.

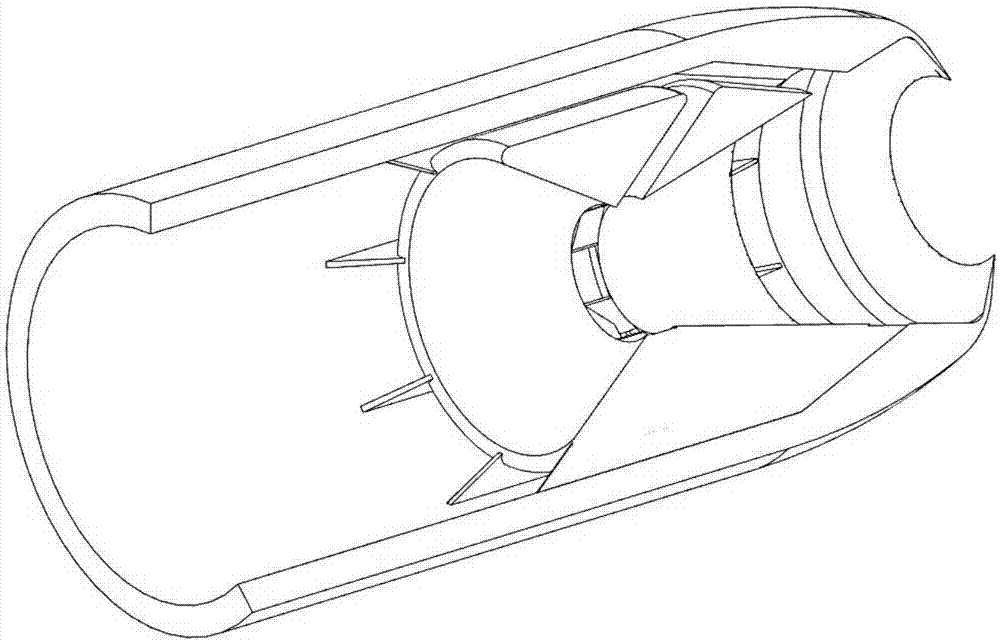

[0028] Such as figure 2 Shown is the schematic diagram of the present invention applied to the inner profile of the ternary double-throat nozzle, the inner profile of the ternary double-throat nozzle is generally circular and axisymmetric; and figure 1 Similar to the binary du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com