Embedded friction clutch

A friction clutch and embedded technology, applied in the direction of clutches, automatic clutches, couplings, etc., can solve problems such as unsatisfactory requirements, and achieve the effect of easy production, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

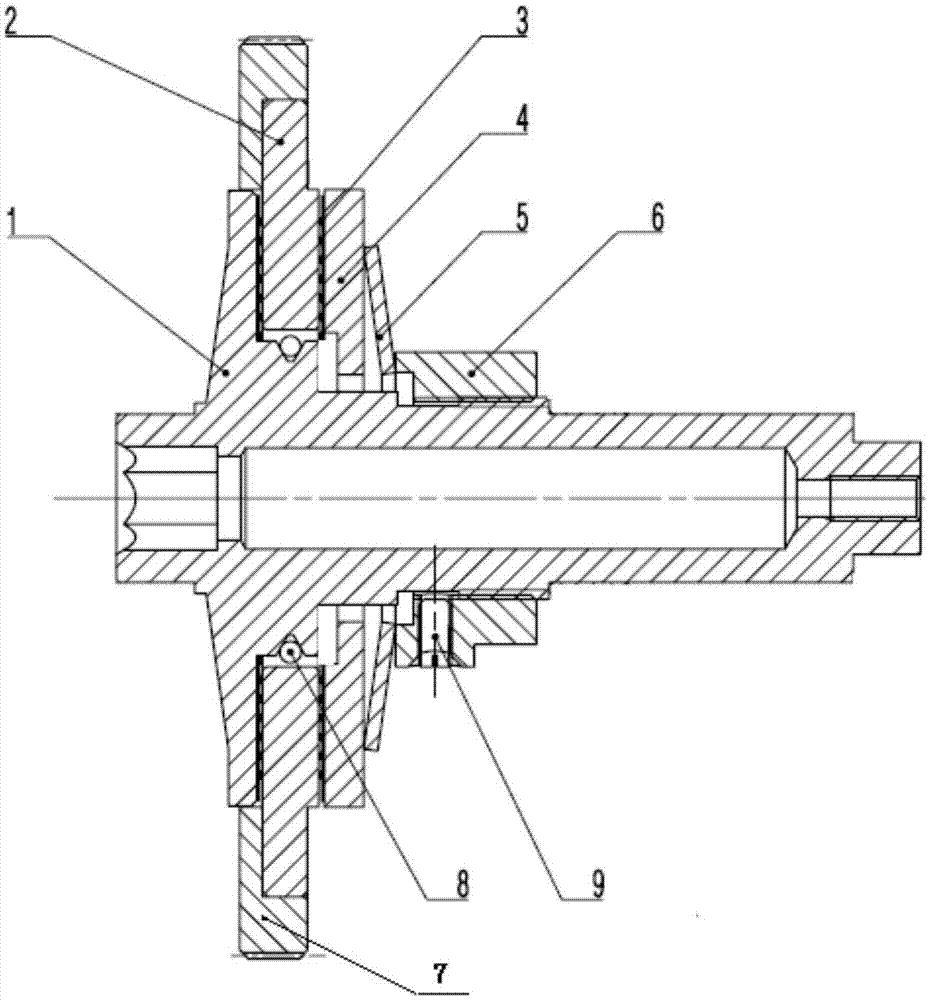

[0014] An embedded friction clutch used in the executive mechanism of the airborne automatic flight control system, the friction clutch includes an output shaft 1, a friction disc 2, a powder metallurgy tin bronze friction plate 3, a pressure sleeve 4, a disc spring 5, and a thrust nut 6. The input gear 7 and the steel ball 8, wherein, the output shaft 1 has an umbrella structure on one side, and the umbrella structure protrudes to the other side with an annular step, and there is a circumferential V on the annular surface of the annular step. type groove; the friction disc 2 is set on the annular step, and is connected with the input gear 7 by bolts, which adopts structural steel 38CrMoAl surface nitriding; the powder metallurgy tin bronze friction plate 3, pressure sleeve 4, The disc spring 5 and the thrust nut 6 penetrate from the other side of the output shaft 1 in turn, and apply pressure to the friction disc 2 through the threaded connection between the thrust nut 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com