Ignition combustion assisting device for garbage thermal cracking furnace

A technology of ignition-supporting combustion and thermal cracking, applied in combustion ignition, incinerators, combustion methods, etc., can solve the problems of easy generation of a large amount of harmful gases, insufficient combustion of garbage, troublesome exhaust gas treatment, etc., to promote complete combustion and decomposition, promote sufficient Combustion, the effect of improving thermal combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

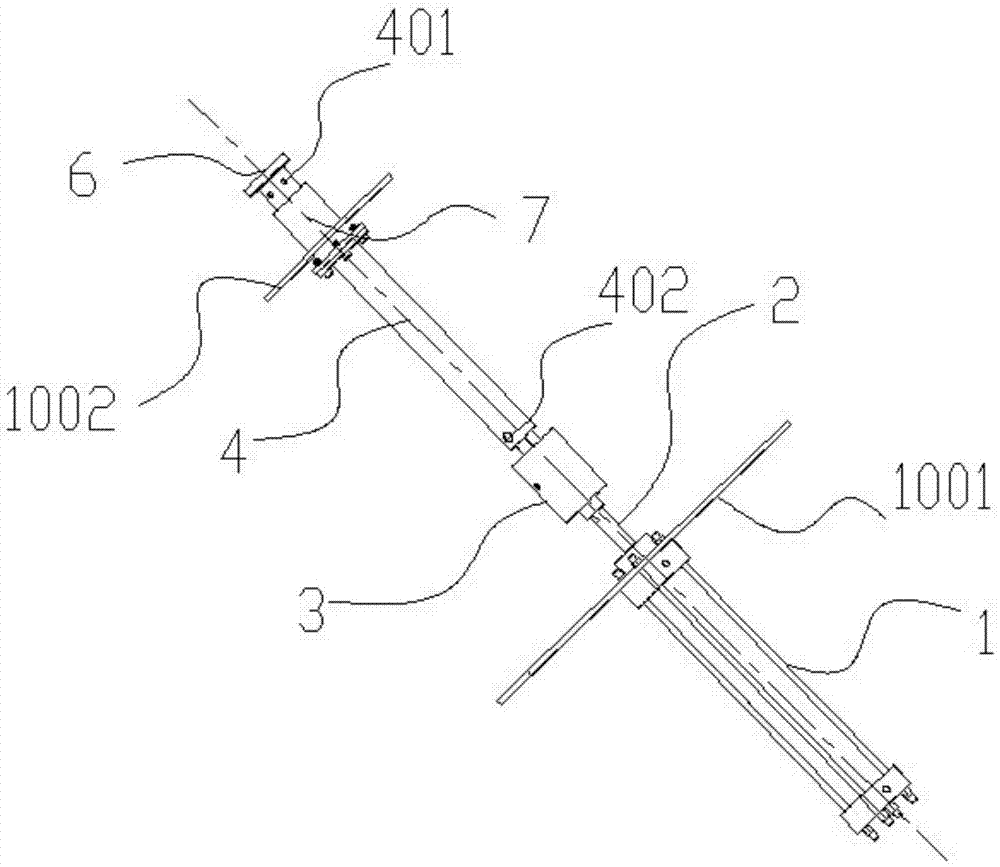

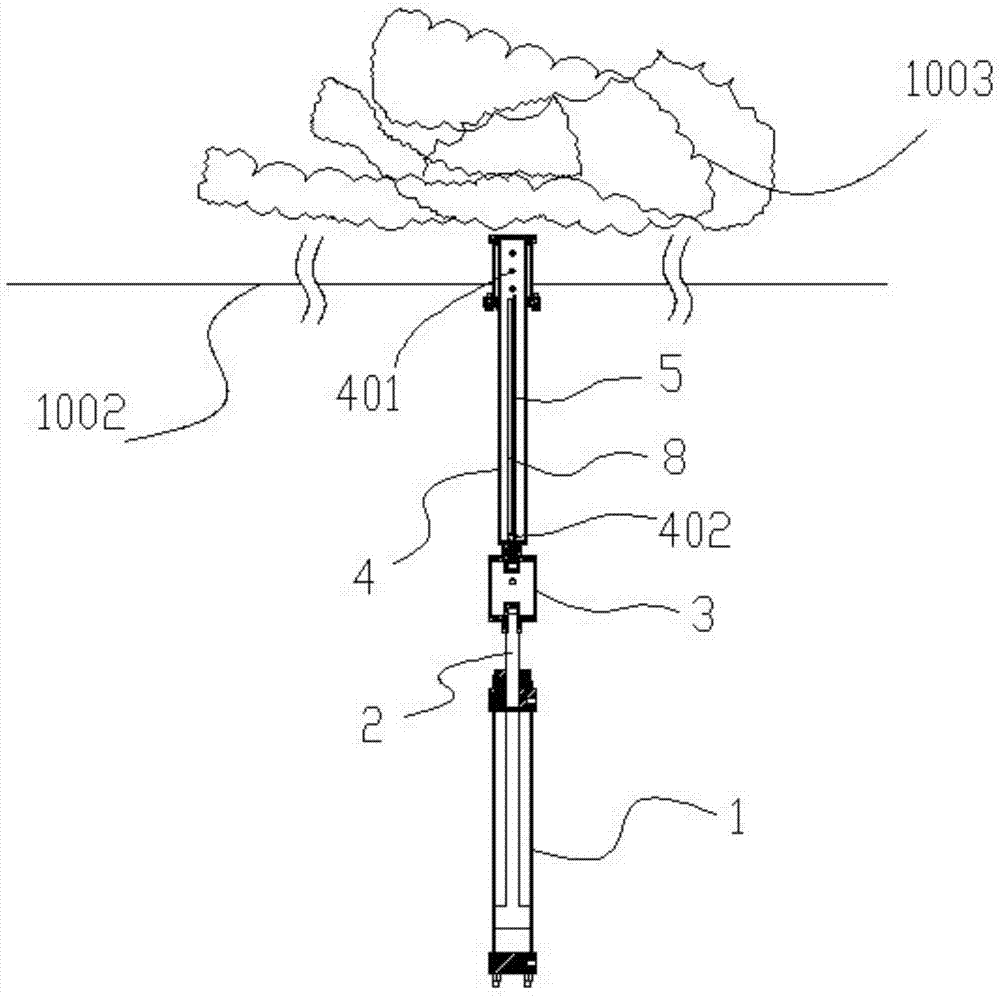

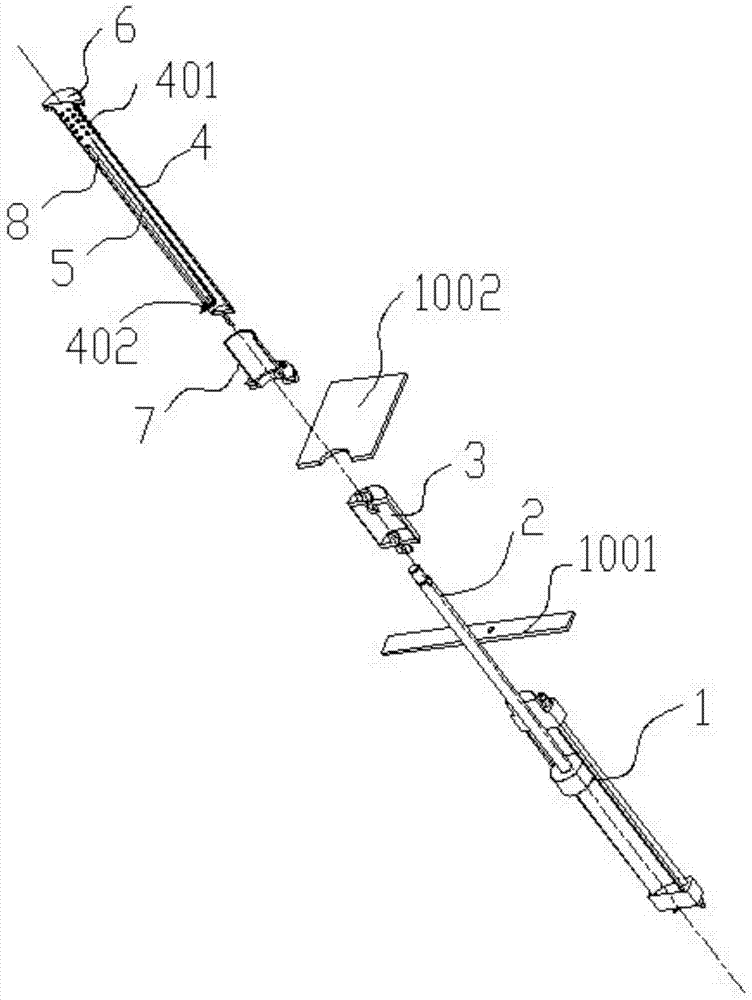

[0030] Such as Figure 1-Figure 6 Shown, the specific structure of the present invention is: a kind of ignition and combustion-supporting device that is used for rubbish pyrolysis furnace, and it is arranged on the bottom of pyrolysis furnace, and it comprises telescopic device 1 at the bottom and the pull rod 2 that telescopic device 1 front end is provided with, pull rod 2. The front end is connected to the ejector rod 4; the ejector rod 4 is hollow and the top end is provided with a cap 6, and the upper side wall of the ejector rod 4 is provided with a number of fire spray holes 401, and the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com