Method for quickly detecting quality of frying oil based on synchronous fluorometry

A technology of synchronous fluorescence and synchronous fluorescence spectroscopy, which is applied in the field of rapid detection of frying oil quality based on synchronous fluorescence method, can solve the problems of time-consuming, toxic reagents, etc., and achieve the effects of improved food safety, easy operation, and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 1. Preparation of oil samples

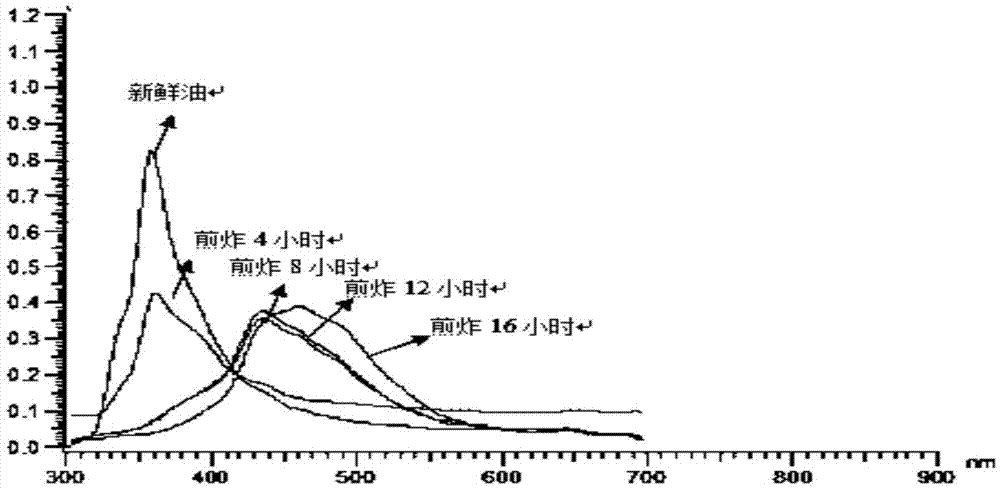

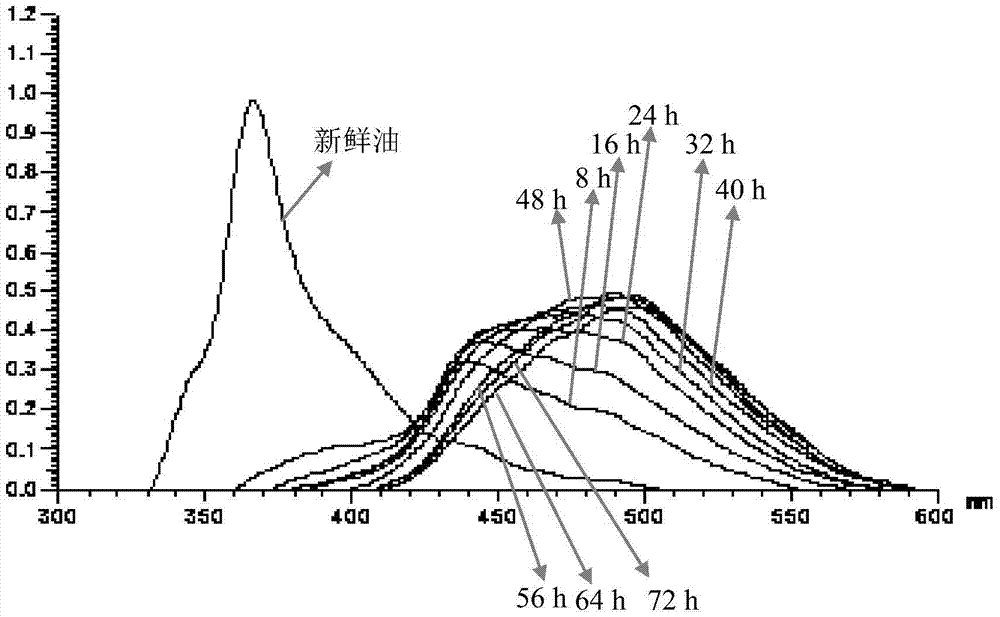

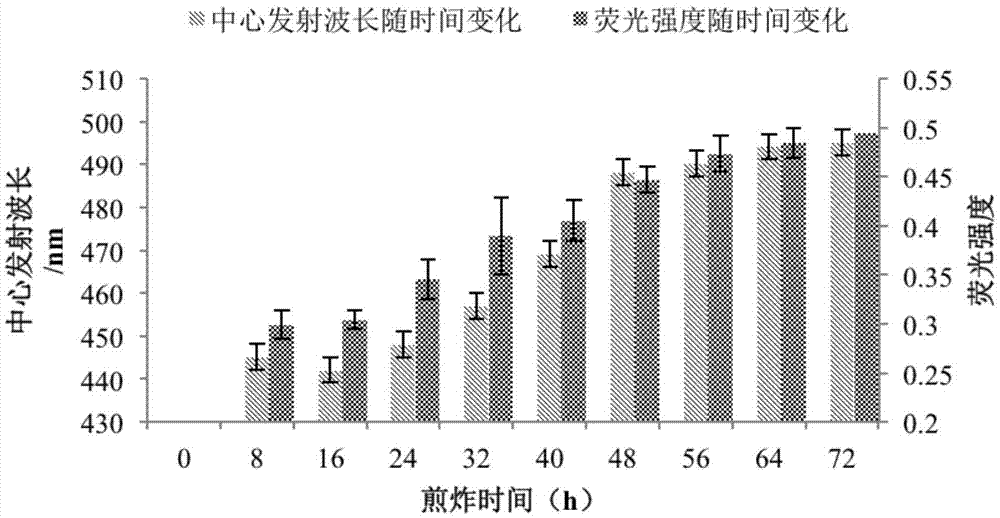

[0032] Control the oil tank at 180±5°C to fry the fried dough sticks, take a sample every 8 hours, and take a total of 9 to 10 samples. Make up oil after each sampling. After the oil sample was taken out, it was placed in the refrigerator and stored at 8°C.

[0033] 2. Simultaneous fluorescence spectrometry

[0034] Perform simultaneous fluorescence spectroscopy scans on the same set of oil samples from step 1.

[0035] The slit width will affect the fluorescence intensity, the larger the slit width, the stronger the fluorescence intensity, but too large slit width will lead to low resolution. If you need to observe two peaks that are close to each other, you can choose to reduce the width of the slit to increase the resolution. For the situation that contains complex fluorescent substances and needs to observe multiple target peaks, the appropriate width of the slit should be selected. In order to better eliminate stray light and rec...

Embodiment 1

[0044] The frying oil is soybean oil, and the frying material is fried dough sticks. The specific implementation process is as follows:

[0045] (1) Establishment of the correlation model between the simultaneous fluorescence peak response of frying oil and common physical and chemical indicators

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com