Product quality online detection X-ray apparatus

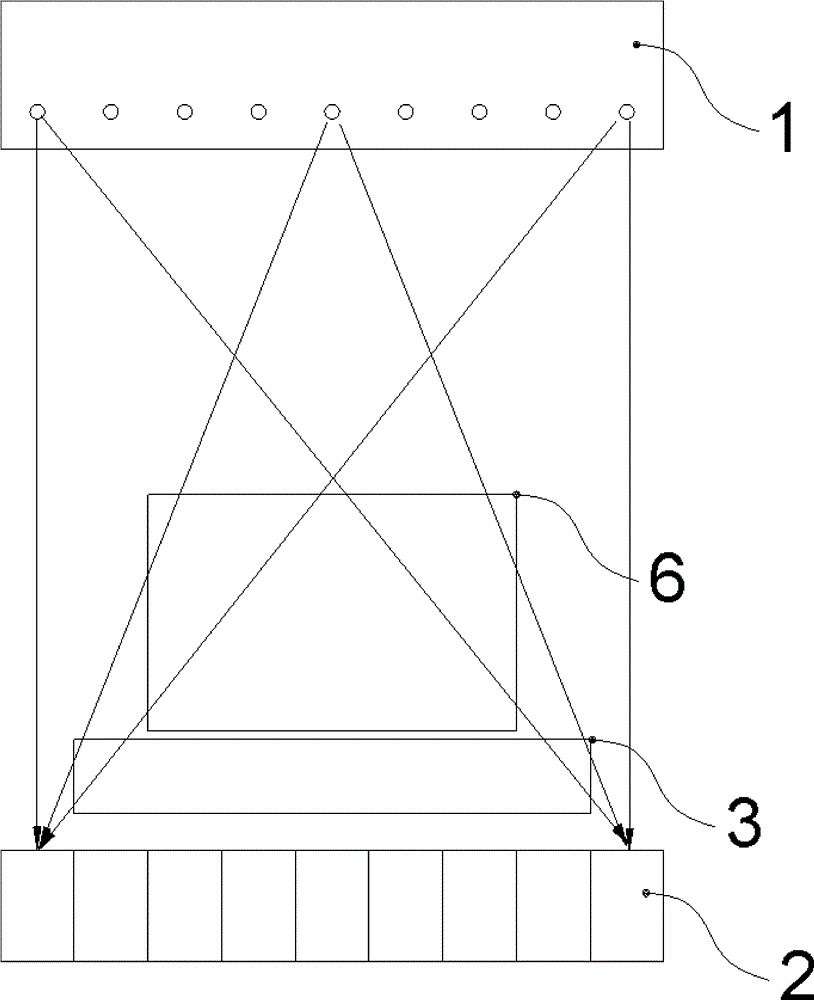

A product quality and detection device technology, which is applied in the direction of material analysis and sorting using radiation, can solve the problems of difficulty in matching the production speed requirements of the assembly line, limited image omnidirectional effect, and limited effective viewing angle range, etc., to achieve fast detection speed, Detect the effect of no dead angle and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

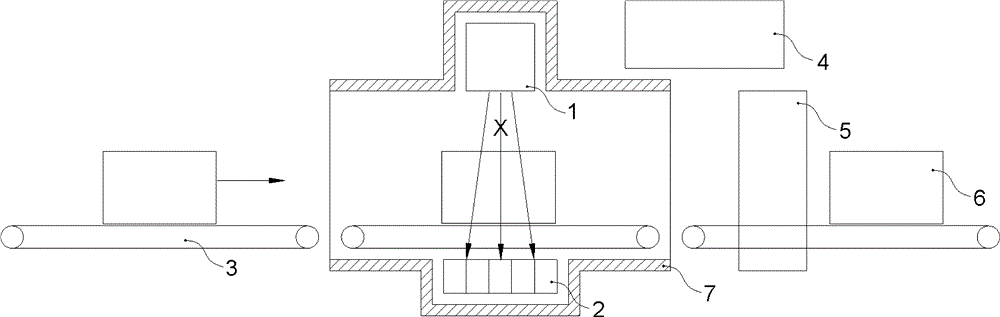

[0068] The second embodiment is an X-ray product quality online inspection device. Except for the transmission device 3 that is different from the first embodiment, the structure and working principle of other parts are the same as those of the first embodiment, that is, in this embodiment Among them, the conveying device 3 is located between the distributed X-ray source 1 and the detector 2, carries the inspected product 6 through the X-ray radiation area, and is arranged in a continuous conveying structure matching the production line of the inspected product 6.

[0069] In this Embodiment 2, the arrangement of the conveying device 3 as a continuous conveying structure matching the production line formation of the product under inspection 6 means: (1) the conveying capacity of the conveying device 3 matches the conveying capacity of the production line, that is, All the inspected products 6 produced on the production line within a unit time can be carried by the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com