Power signal composite cable

A power signal and composite cable technology, applied in the direction of insulated cables, power cables, communication cables, etc., can solve the problems of lack of flexibility in the wiring system and low efficiency of wiring construction, so as to improve the efficiency of on-site wiring, simplify on-site wiring operations, and facilitate local The effect of wiring optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

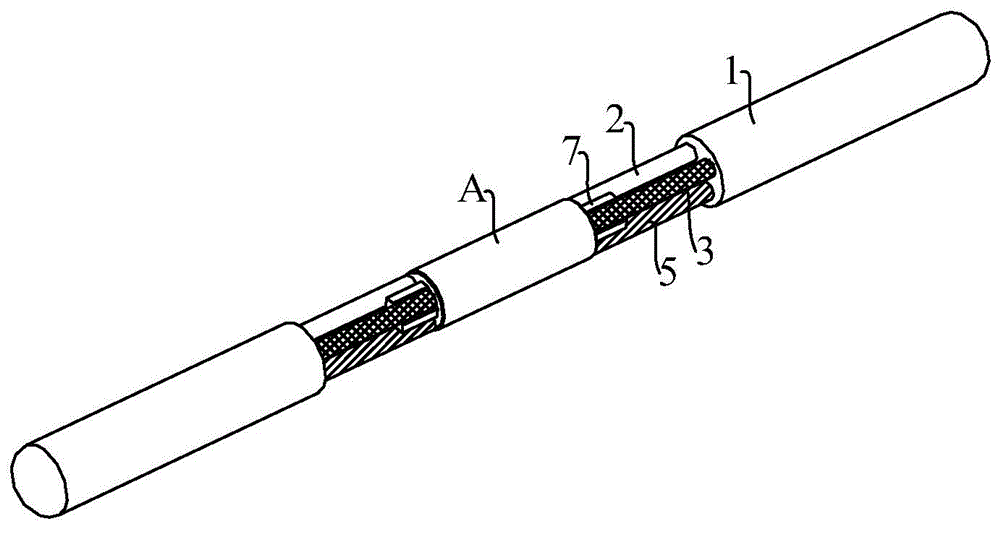

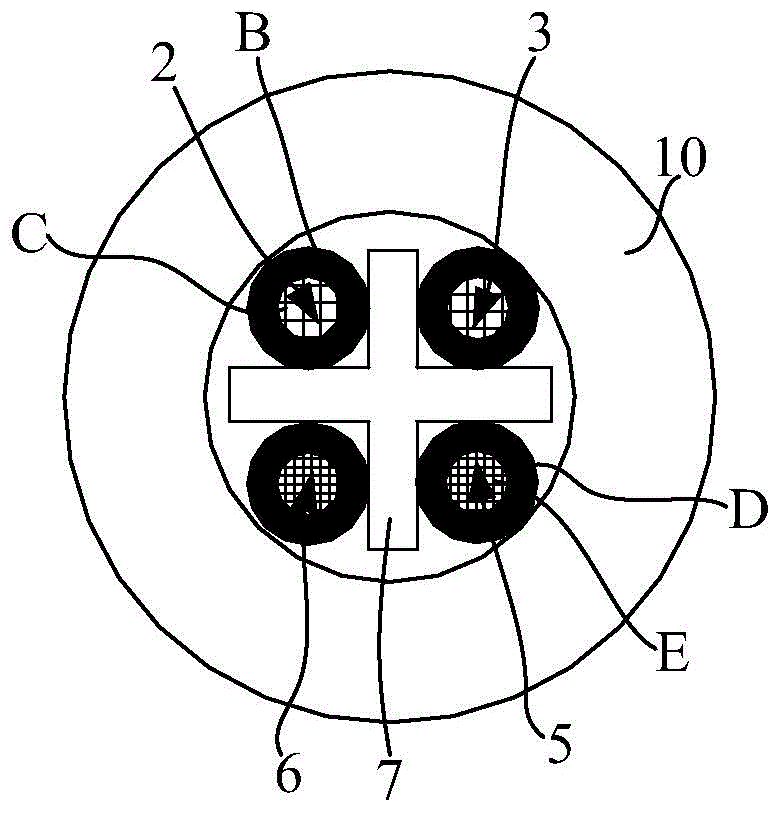

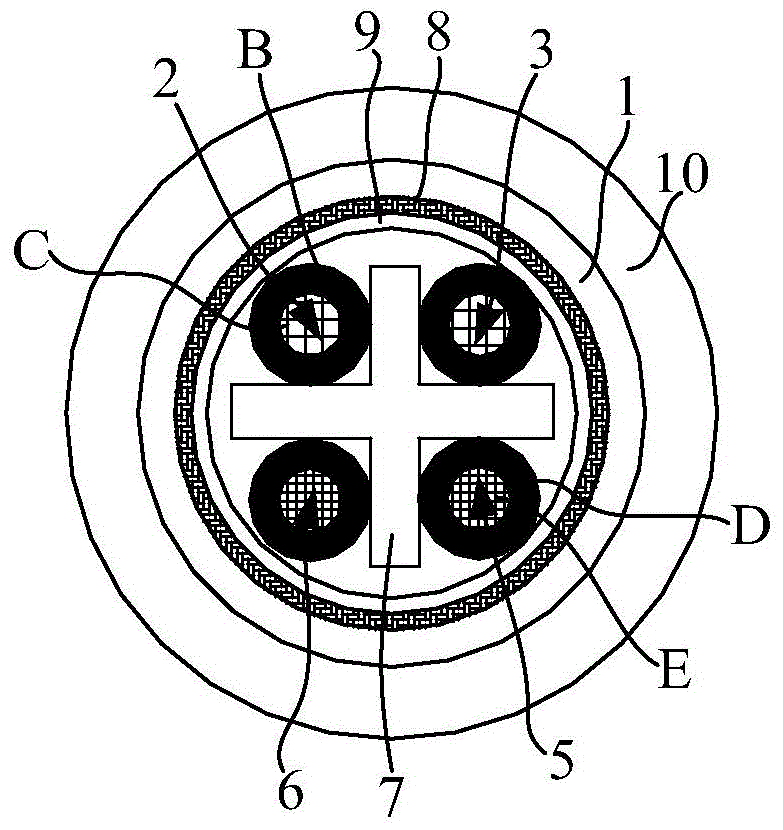

[0053] Please refer to the attached Figure 1-3 , figure 1 It is a partial structural diagram of the power signal composite cable provided by Embodiment 1 of the present invention. figure 2 It is a transverse cross-sectional view of the power signal composite cable provided with cross-node equipment according to Embodiment 1 of the present invention. image 3 It is a transverse cross-sectional view of the power signal composite cable provided by Embodiment 1 of the present invention including the cable base material.

[0054] The power signal composite cable provided by Embodiment 1 of the present invention includes at least two sections of base cables, a cross node device 7 and a plastic-molded outer sheath 10 .

[0055] Each segment of the base cable includes a first signal wire 5 , a second signal wire 6 , a live wire 2 , a ground wire 3 and an outer sheath 1 of the base cable.

[0056] The first signal line 5 and the second signal line 6 are usually cables commonly use...

Embodiment 2

[0096] Can be combined with reference Figure 1-3 , The power signal composite cable provided by Embodiment 2 of the present invention includes at least two sections of base cables, a cross node device 7 and a plastic-molded outer sheath 10 .

[0097] Each segment of the base cable includes a first signal wire 5 , a second signal wire 6 , a live wire 2 , a ground wire 3 and an outer sheath 1 of the base cable.

[0098] The first signal line 5 and the second signal line 6 are usually cables commonly used in the communication field, such as 485 signal lines. The outer sheath 1 of the base cable is wrapped outside the cable bundle formed by the first signal wire 5 , the second signal wire 6 , the live wire 2 and the ground wire 3 , and is an outer protective part of the base cable. Usually, the base cable outer sheath 1 can be made of PVC (Polyvinylchloride, polyvinyl chloride), LSZH (Low Smoke Zero Halogen, low smoke zero halogen) material or PE (polyethylene, polyethylene) mat...

Embodiment 3

[0142] Can be combined with reference Figure 1-3 , The power signal composite cable provided by Embodiment 3 of the present invention includes at least two sections of base cables, a cross node device 7 and a plastic-molded outer sheath 10 .

[0143] Each segment of the base cable includes a first signal wire 5 , a second signal wire 6 , a live wire 2 , a ground wire 3 and an outer sheath 1 of the base cable.

[0144] The first signal line 5 and the second signal line 6 are usually cables commonly used in the communication field, such as 485 signal lines. The outer sheath 1 of the base cable is wrapped outside the cable bundle formed by the first signal wire 5 , the second signal wire 6 , the live wire 2 and the ground wire 3 , and is an outer protective part of the entire base cable. Usually, the base cable outer sheath 1 can be made of PVC (Polyvinylchloride, polyvinyl chloride), LSZH (Low Smoke Zero Halogen, low smoke zero halogen) material or PE (polyethylene, polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com