Method for removing ITO (tin indium oxide) on surface of base plate

A substrate surface and substrate technology, which is applied in the field of ITO removal on the substrate surface, can solve the problems of etching cost, difficult safety control, easy cracking, easy acid leakage at the edge of the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The method for removing the ITO on the substrate surface of embodiment 1 comprises the following steps:

[0055] (1) Use alcohol with a concentration of 99.7% to wipe the substrate with ITO on the surface to remove surface stains. In the substrate with ITO on the surface, the material of the substrate is a TFT glass substrate, and the thickness of the substrate is 0.4mm. The thickness is 25nm.

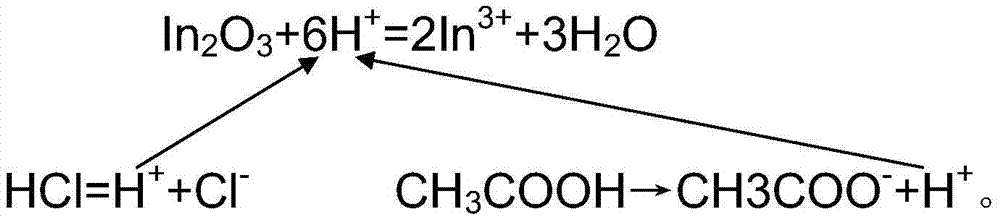

[0056] (2) The substrate with ITO on the surface is placed in an acid tank and soaked for 10 minutes for pickling. The acid solution in the acid tank includes 20% hydrochloric acid, 30% acetic acid and 50% water by weight percentage. Bubble tubes are installed at the bottom of the tank to improve the speed and uniformity of pickling.

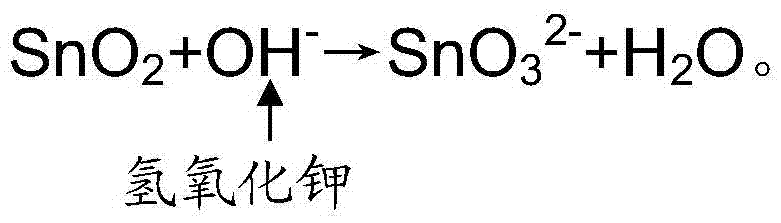

[0057] (3) Soak the substrate with ITO on the pickled surface in flowing pure water for 10 minutes to remove the acid solution on the surface, then place the substrate with ITO in an alkali tank to soak for 10 minutes for alkali cleaning, the The ...

Embodiment 2

[0061] The method for removing the ITO on the substrate surface of embodiment 2 comprises the following steps:

[0062] (1) Use alcohol with a concentration of 99.7% to wipe the substrate with ITO on the surface to remove surface stains. In the substrate with ITO on the surface, the material of the substrate is a TFT glass substrate, and the thickness of the substrate is 0.4mm. The thickness is 25nm.

[0063] (2) The substrate with ITO on the surface is placed in an acid tank and soaked for 10 minutes for pickling. The acid solution in the acid tank includes 22% hydrochloric acid, 33% acetic acid and 45% water by weight percentage. Bubble tubes are installed at the bottom of the tank to improve the speed and uniformity of pickling.

[0064] (3) Soak the substrate with ITO on the pickled surface in flowing pure water for 10 minutes to remove the acid solution on the surface, then place the substrate with ITO in an alkali tank to soak for 10 minutes for alkali cleaning, the Th...

Embodiment 3

[0068] The method for removing the ITO on the substrate surface of embodiment 3 comprises the following steps:

[0069] (1) Use alcohol with a concentration of 99.7% to wipe the substrate with ITO on the surface to remove surface stains. In the substrate with ITO on the surface, the material of the substrate is a TFT glass substrate, and the thickness of the substrate is 0.4mm. The thickness is 25nm.

[0070] (2) The substrate with ITO on the surface is placed in an acid tank and soaked for 10 minutes for pickling. The acid solution in the acid tank includes 25% hydrochloric acid, 35% acetic acid and 40% water. Bubble tubes are installed at the bottom of the tank to improve the speed and uniformity of pickling.

[0071] (3) Soak the substrate with ITO on the pickled surface in flowing pure water for 10 minutes to remove the acid solution on the surface, then place the substrate with ITO in an alkali tank to soak for 10 minutes for alkali cleaning, the The lye comprises 10% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com