Heat-insulating composition, method of preparing the same, and heat-insulating element using the same

A composition and polymer technology, applied in heat exchange equipment, chemical instruments and methods, and protection of pipelines through thermal insulation, etc., can solve problems such as inability to achieve thermal insulation properties, and achieve excellent economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

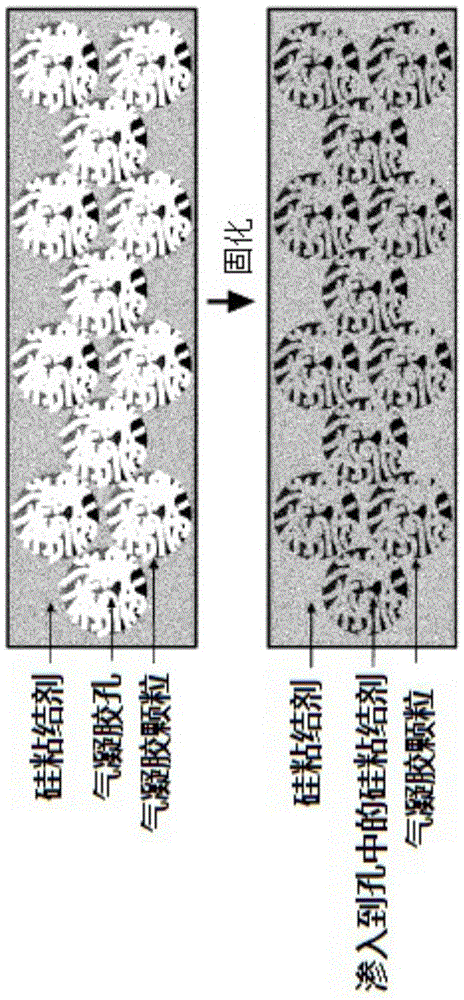

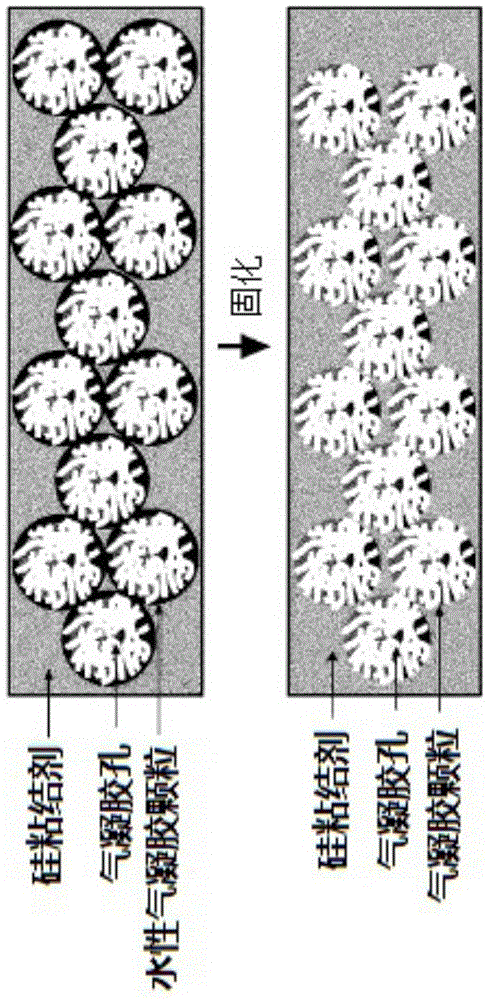

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: Preparation of thermal insulation composition

[0080] A gel-like aqueous solution was prepared by mixing 10 g of a superabsorbent polymer (SAP) (HI-SWELL available from SONGWON), 5 g of carboxymethylcellulose, and 200 g of water. Here, the viscosity of the gel-like aqueous solution measured with a viscometer (SV-10kv from AND Company) was 5200CP.

[0081] Subsequently, 50 g of airgel was added to the above aqueous solution using a fast stirrer at a rotational speed of 2500 rpm, and stirred for 20 minutes, thus obtaining an aqueous airgel composition in which the airgel was uniformly dispersed.

[0082] 100 g of the obtained aqueous airgel composition and 100 g of a high-temperature silicon binder (50% by dry weight) were mixed, thus obtaining a thermal insulation composition.

Embodiment 2

[0091] Example 2: Manufacture of thermal insulation elements

[0092] The thermal insulation composition obtained in Example 1 is coated on a glass fiber mat (120g / m2) of about 0.5mm thickness 2 low density) and then stacked to have a thickness of 1 mm to obtain a laminate, which was stacked and folded 4 times, and then dried at 120° C. for 3 hours to manufacture a heat insulating element.

Embodiment 3

[0093] Example 3: Manufacture of thermal insulation elements

[0094] A gel-like aqueous solution was prepared by mixing 10 g of a superabsorbent polymer (SAP) (HI-SWELL available from SONGWON), 5 g of carboxymethylcellulose, and 200 g of water. Here, the viscosity of the gel-like aqueous solution measured with a viscometer (SV-10kv from AND Company) was 5200CP.

[0095] Subsequently, 50 g of airgel was added to the above aqueous solution using a fast stirrer at a rotational speed of 2500 rpm, and stirred for 20 minutes, thus obtaining an aqueous airgel composition in which the airgel was uniformly dispersed.

[0096] 100 g of the obtained aqueous airgel composition, 70 g of high-temperature silicon binder (50% by dry weight) and 30 g of water glass solution were mixed, thus obtaining a thermal insulation composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water sorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com