Thermal mass flow meter

一种质量流量计、质量流量的技术,应用在测量流量/质量流量、使用热变量测量流体速度、测量装置等方向,能够解决温度平衡破坏、热式流量计破损、传感器部热劣化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

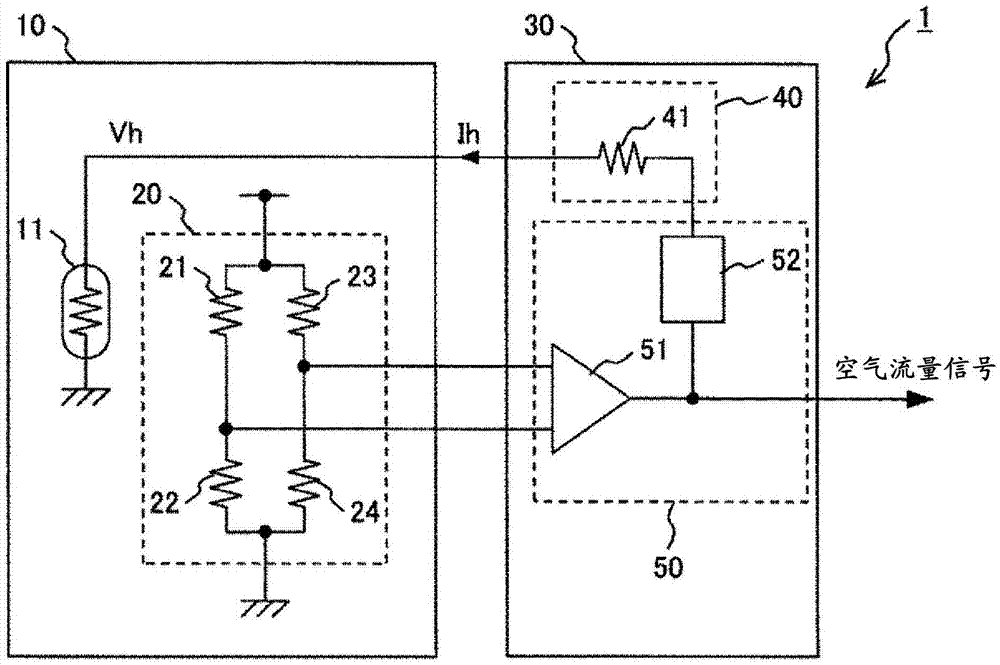

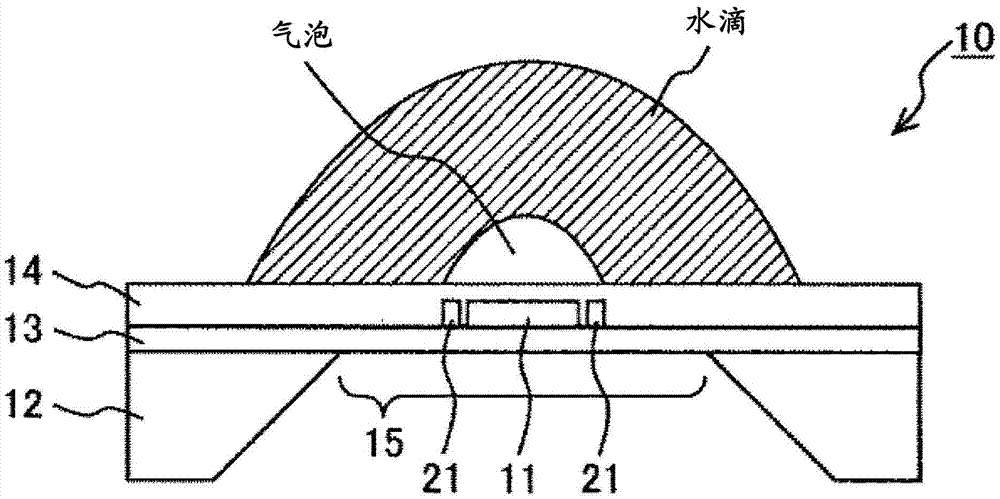

[0056] pass Figure 1 ~ Figure 4 A thermal mass flowmeter according to a first embodiment of the present invention will be described.

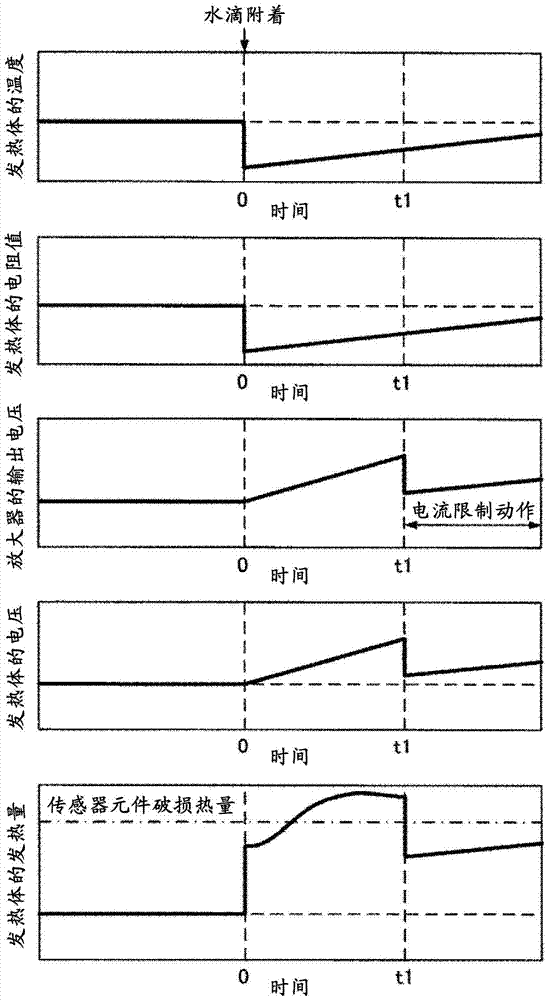

[0057] figure 1 It is a schematic circuit diagram showing the configuration of the thermal mass flowmeter of the first embodiment. Such as figure 1 As shown, the thermal mass flowmeter 1 of the first embodiment has: a sensor element unit 10 having a heating element 11 that generates heat by energization and a temperature detection bridge circuit 20 that detects the temperature of the heating element 11; The circuit unit 30 is connected to the sensor element unit 10 and controls the conduction of electricity to the heating element 11 . The temperature detection bridge circuit 20 is composed of a temperature detection resistor 21 whose resistance value changes according to temperature, and constant resistors 22 to 24 whose resistance value is constant.

[0058] The sensor element drive circuit unit 30 has an output mechanism 50 and an output...

no. 2 approach

[0070] pass Figure 5-11 A thermal mass flowmeter according to a second embodiment of the present invention will be described.

[0071] Figure 5 It is a schematic circuit diagram showing the configuration of the thermal mass flowmeter of the second embodiment. Such as Figure 5As shown, the thermal mass flowmeter 2 of the second embodiment has the same configuration as the sensor element unit 10 of the thermal mass flowmeter 1 of the first embodiment, but the sensor element drive circuit unit 31 has a different configuration. The sensor element drive circuit unit 31 of the present embodiment has an output mechanism 70 and an output impedance adjustment mechanism 60 .

[0072] The output mechanism 70 has: an amplifier 71, which detects the output voltage of the temperature detection bridge circuit 20; a MOS transistor 72, which receives the output of the amplifier 71; a resistor 73 and a MOS transistor 74 connected in series with the MOS transistor 72; a MOS transistor 75, ...

no. 3 approach

[0080] pass Figure 12 A thermal mass flowmeter according to a third embodiment of the present invention will be described.

[0081] Figure 12 It is a schematic circuit diagram showing the configuration of the thermal mass flowmeter of the third embodiment. Such as Figure 12 As shown, the thermal mass flowmeter 3 of the third embodiment has a sensor element unit 10 and a sensor element drive circuit unit 32 , and the sensor element drive circuit unit 32 has an output mechanism 70 and an output impedance adjustment mechanism 65 . That is, the thermal mass flowmeter 3 of the third embodiment differs from the thermal mass flowmeter 2 of the second embodiment in the output impedance adjustment mechanism 65 .

[0082] The output impedance adjustment mechanism 65 is different from the output impedance adjustment mechanism 60 in that the resistor 63 is arranged in the rear stage of the MOS transistor 62, and the output impedance of the sensor element drive circuit section 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com