Microtube distillation and condensation method and device

A distillation condensing device and distillation condensing technology, which are applied in the microtube distillation condensing device and the field of microtube distillation condensing using the device, can solve the problems of inaccurate data, fragility, and large consumption of reagents, etc., to prevent liquid bumping , the effect of preventing bumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

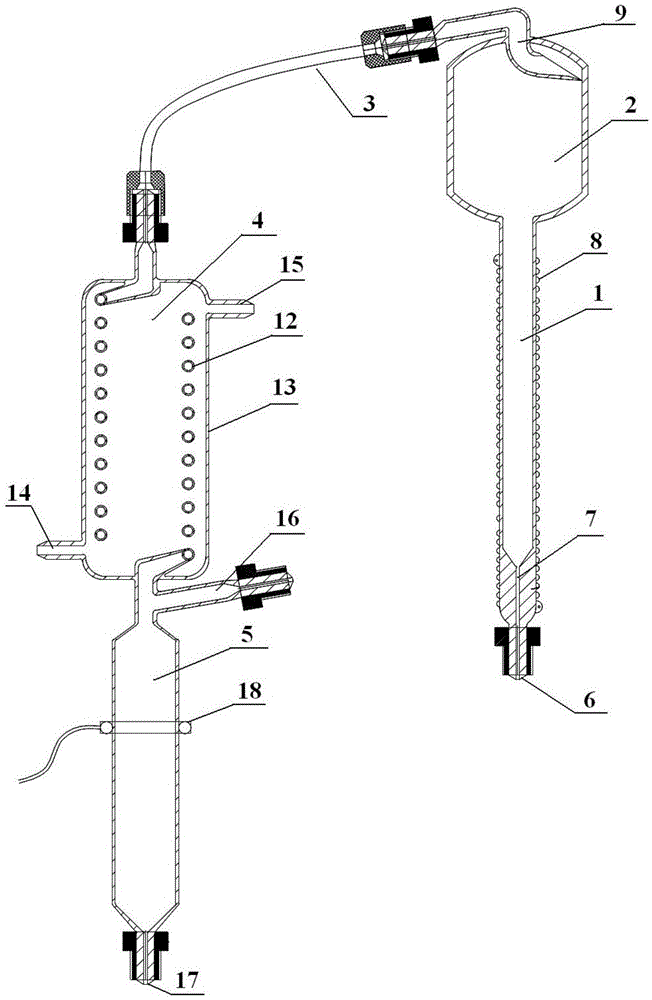

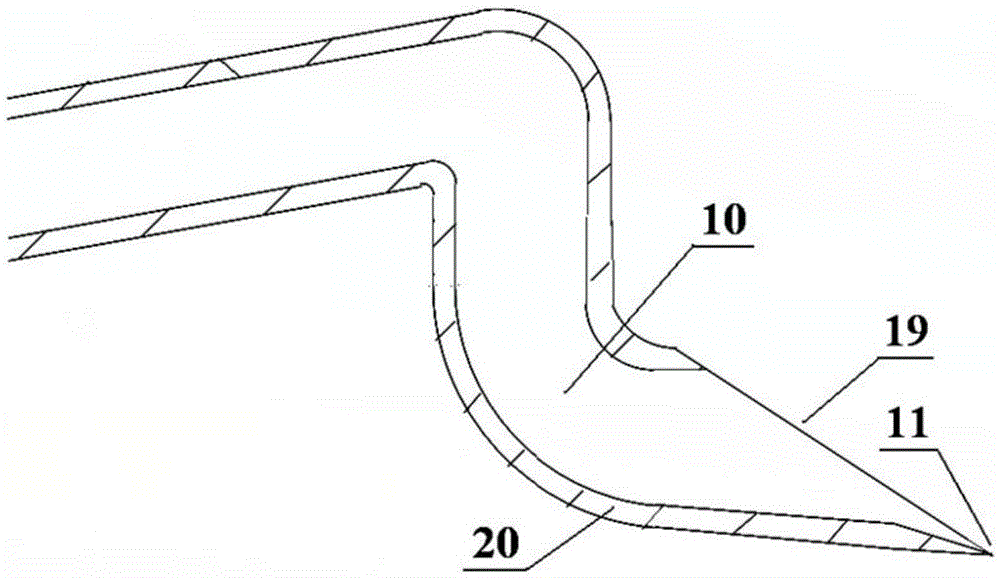

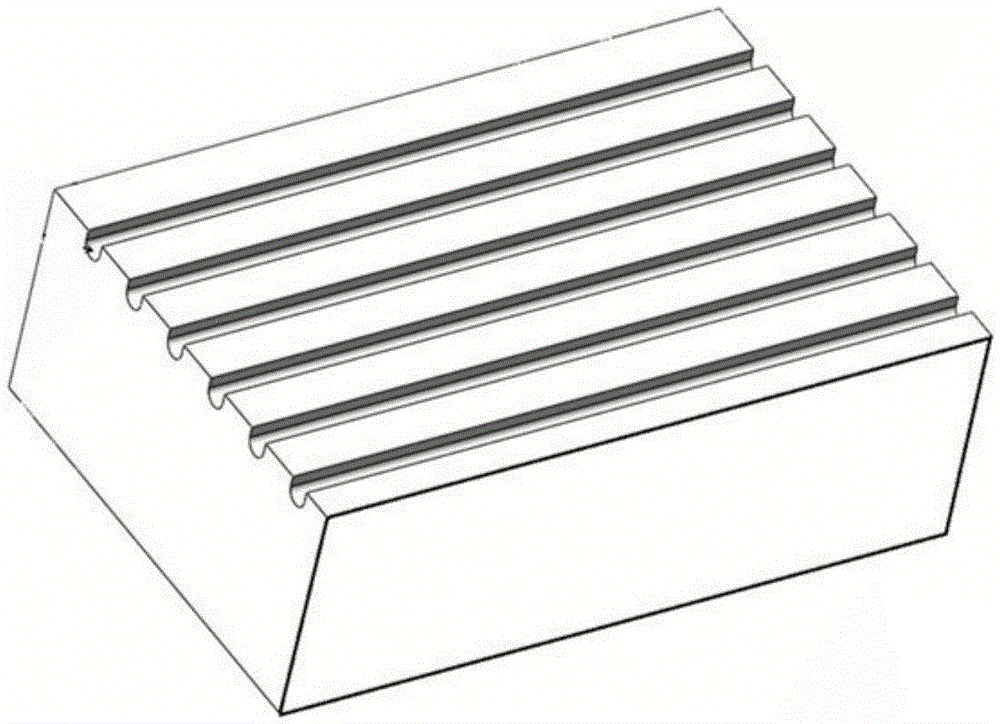

[0028] A micropipe distillation and condensation method comprises a micropipe heating unit, a gas-liquid separation unit and a condensation collection unit, the micropipe heating unit is located below the gas-liquid separation unit, and the gas-liquid separation unit and the condensation collection unit are connected by connecting thin tubes. The inner wall of the microtube heating unit is provided with a characteristic concave-convex structure, which is in contact with the distilled liquid in the microtube heating unit. During heating, the characteristic concave-convex structure will preferentially generate bubbles, and continue the entire heating process, inhibiting the accumulation of superheated liquid in the distilled liquid and avoiding exposure. boiling; the outer wall of the microtube heating unit is wound with a heating wire for heating....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com