Reaction system used for producing active gasoline synergist

A technology of reaction system and synergist, applied in the field of reaction system, can solve the problems of reduced engine efficiency, complex reaction system, high cost, etc., and achieve the effect of scientific and reasonable design, simple reaction system and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

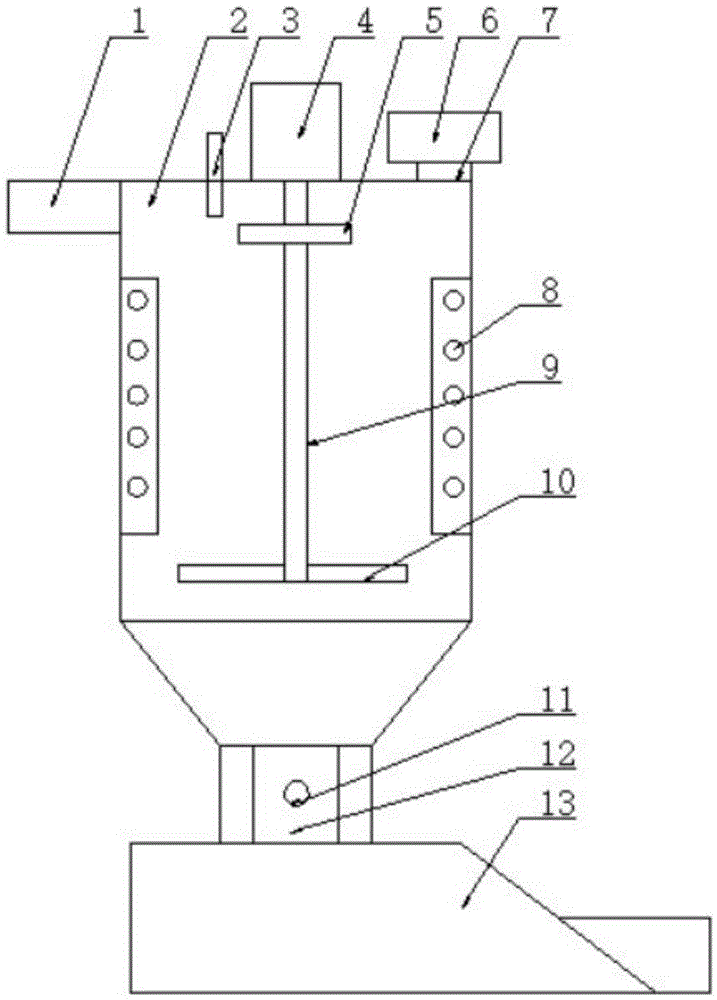

[0014] A kind of reaction system that is used to produce active gasoline synergist, this reaction system comprises a reactor 2, and it installs motor 4 at the reactor upper end, and this motor output shaft 9 is arranged in the reactor, and the upper part installed on this output shaft The stirring rod 5 and the lower stirring rod 10 are equipped with a thermocouple 3 on the reaction kettle on the side of the motor, a heater 8 is installed in the middle of the reaction kettle, a feed inlet 1 is formed on the side wall of the upper part of the reaction kettle, and a reaction lower end is formed with a The discharge port 12 is connected to a storage tank 13 . The heater is a heating tube. The heating tube is a quartz heating tube. Check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com