Method for producing manganese sulfate by removing high-concentration SO2 in flue gas by mass-separation and multi-point feeding method

A high-concentration sulfuric acid production technology, which is applied in the field of flue gas desulfurization to manganese sulfate and manganese sulfate preparation, achieves the effects of high desulfurization efficiency, high leaching rate and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

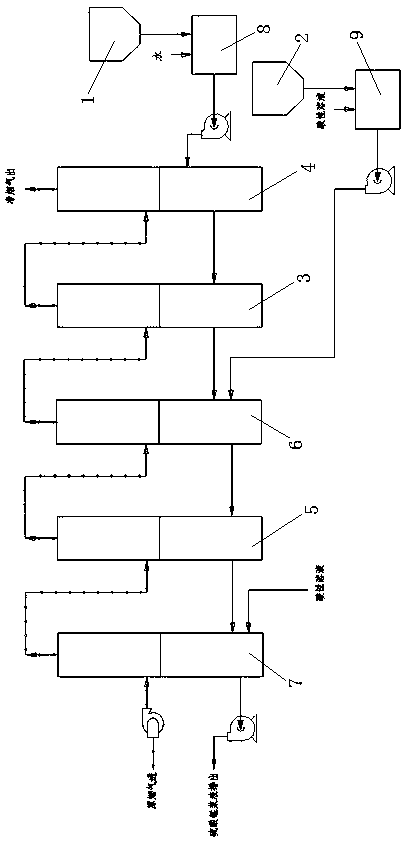

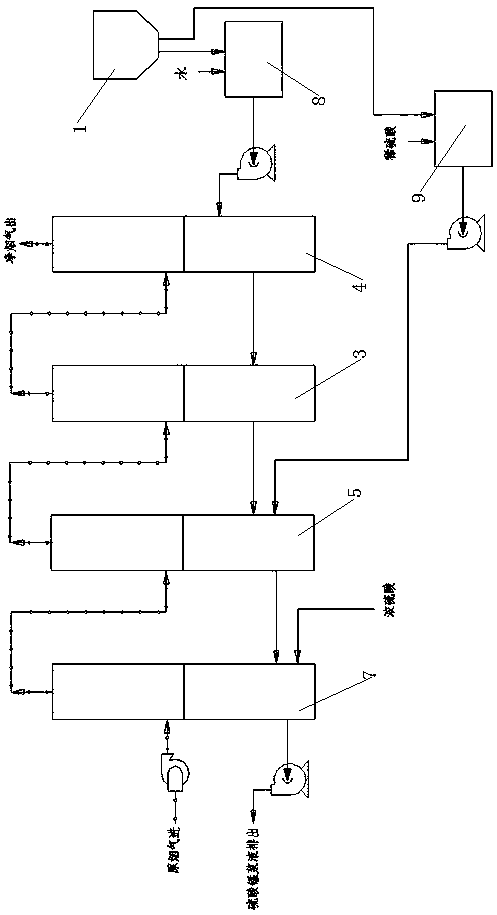

[0051] As shown in the figure, in this embodiment, the first-stage reaction group, the intermediate-stage reaction group, and the latter-stage reaction group are connected in series in sequence. Among them, the post-stage reaction group is the first post-stage reactor, the mid-stage reaction group is formed by connecting the first mid-stage reactor, the second mid-stage reactor, and the third mid-stage reactor in series, and the pre-stage reaction group is the first pre-stage reaction device. In the first stage of reaction, the first manganese ore powder bin and the first slurry mixing tank are used to cooperate with each other to prepare a stage of manganese ore reaction slurry. In the second-stage reaction, the second manganese ore powder bin and the second slurry mixing tank are used to cooperate with each other to prepare the second-stage manganese ore reaction slurry.

[0052] Its reaction process is as follows.

[0053] Flue gas SO after electrostatic precipitator 2 T...

Embodiment 2

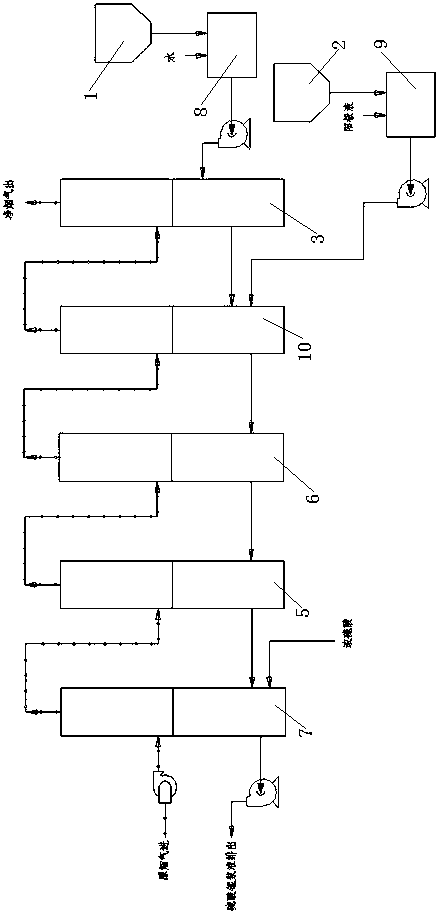

[0060] As shown in the figure, in this embodiment, the first-stage reaction group, the intermediate-stage reaction group, and the latter-stage reaction group are connected in series in sequence. Wherein, the rear-stage reaction group is formed by connecting the first post-stage reactor and the second post-stage reactor in series, the intermediate reaction group is the first intermediate reactor, and the front-stage reaction group is the first front-stage reactor. In the first stage of reaction, the first manganese ore powder bin and the first slurry mixing tank are used to cooperate with each other to prepare a stage of manganese ore reaction slurry. In the second-stage reaction, the first manganese ore powder bin and the second slurry mixing tank are used to cooperate with each other to prepare the second-stage manganese ore reaction slurry.

[0061] Its reaction process is as follows.

[0062] Flue gas SO after electrostatic precipitator 2 The content is 40000mg / m 3 , wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com