An ecological building material crushing system

A crushing system and building materials technology, applied in the field of construction, can solve problems such as poor crushing effect, no screening structure for crushing equipment, and inability to crush raw materials, etc., and achieve good crushing effect, strong practicability, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

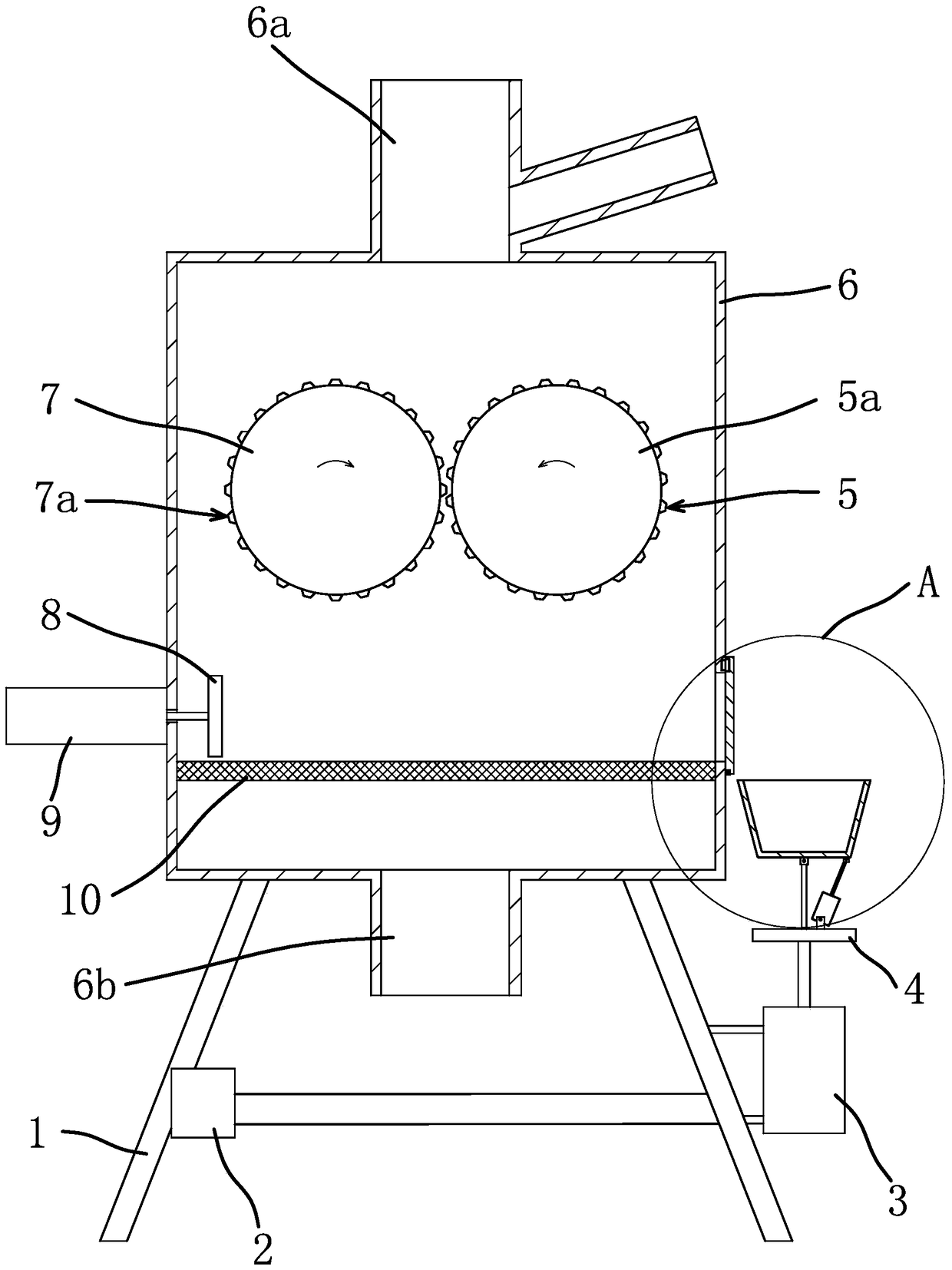

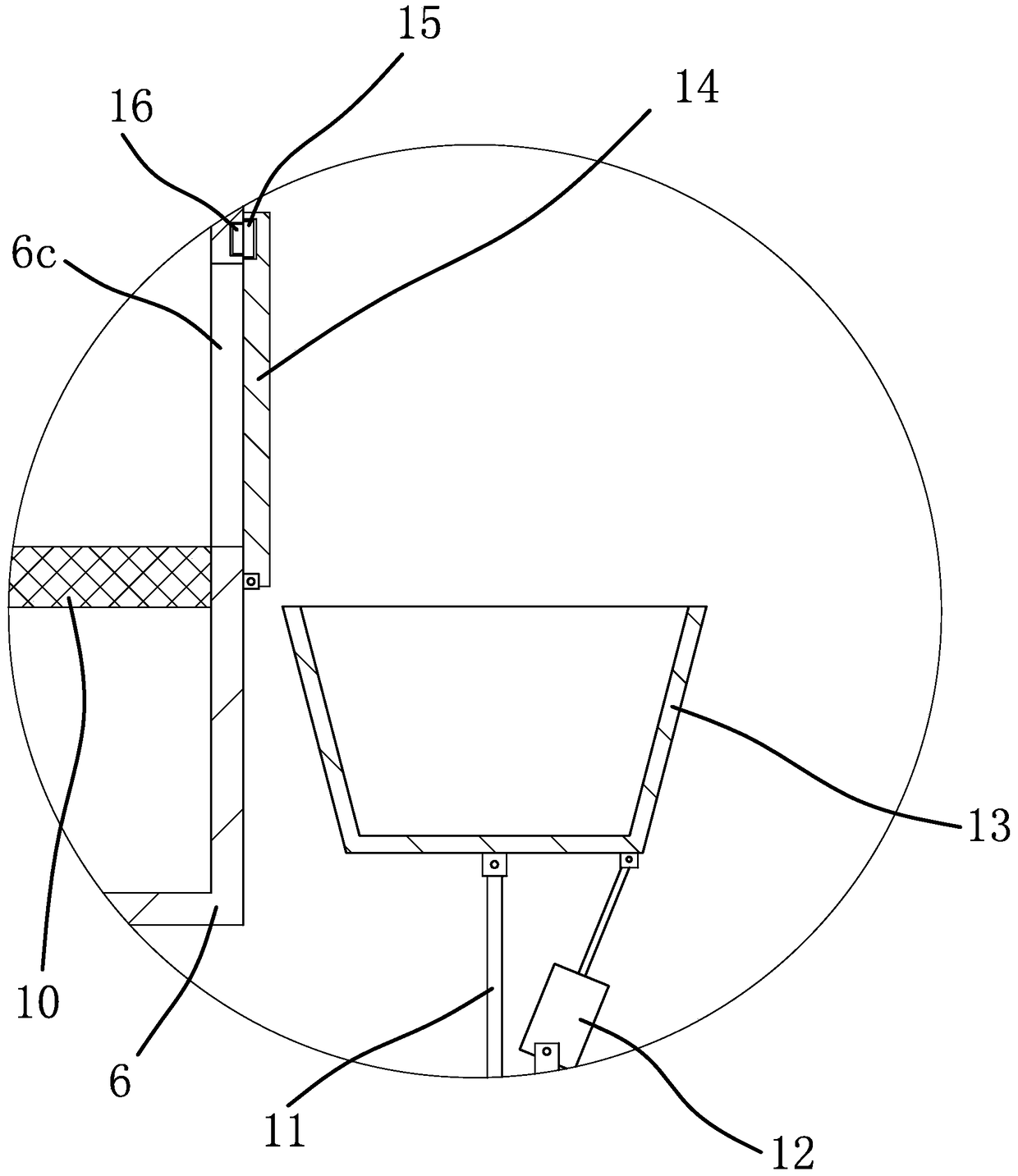

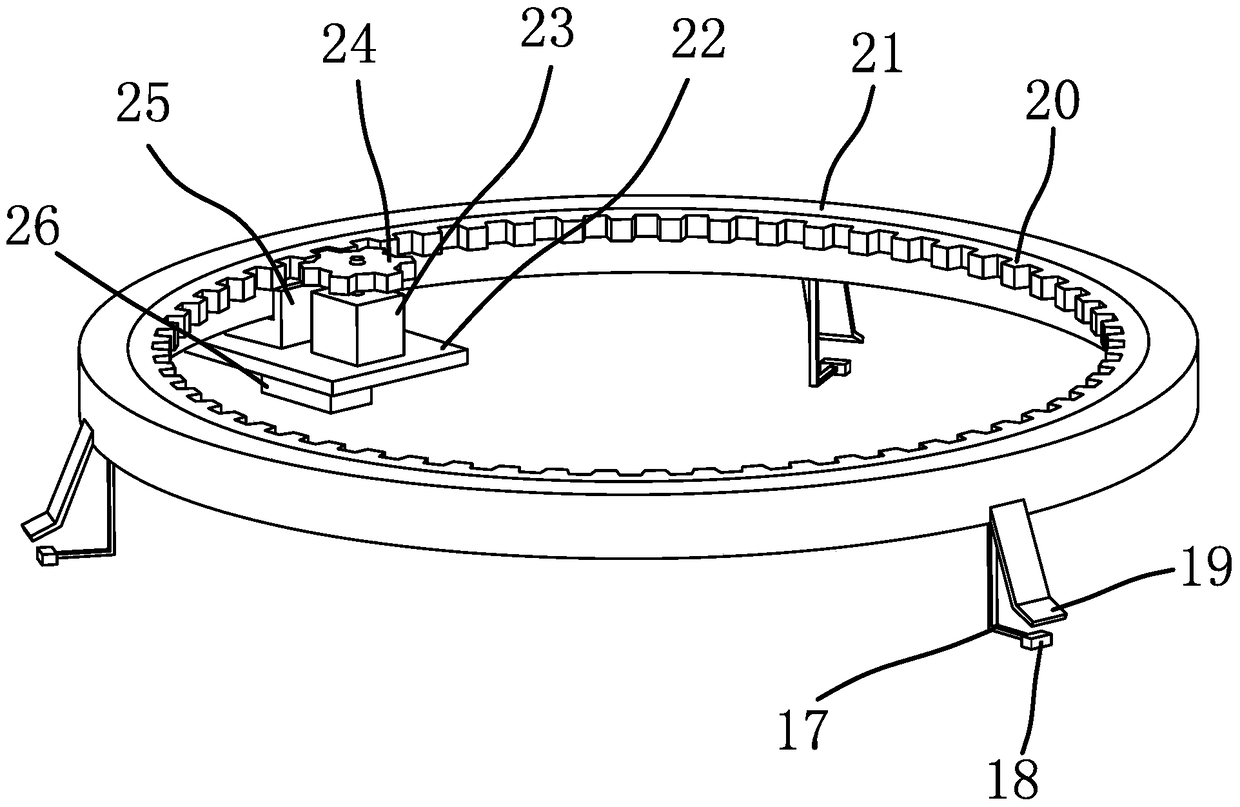

[0031] like figure 1 As shown, the ecological building material crushing system includes a frame 1, a crushing box 6 is arranged on the frame 1, the upper part of the crushing box 6 has a feed inlet 6a, the bottom of the crushing box 6 has a discharge port 6b, and the crushing box 6 is provided with a The active crushing roller shaft 5 and the driven crushing roller shaft 7, the end of the active crushing roller shaft 5 is connected to the drive motor, and the side of the active crushing roller shaft 5 has several first cutters 5a. In this embodiment, the first cutters 5a The number is one hundred; the side of the driven crushing roller shaft 7 has a second cutter 7a corresponding to the first cutter 5a, and in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com