Dust removal device special for integrated circuit board

A technology of integrated circuit board and dust removal device, which is applied in the direction of dust removal, cleaning method and utensils, and cleaning method using tools, etc., which can solve the problems of high labor intensity of dust on integrated circuit boards, large environmental pollution, etc., and avoid flying dust , It is not easy to remove hair, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

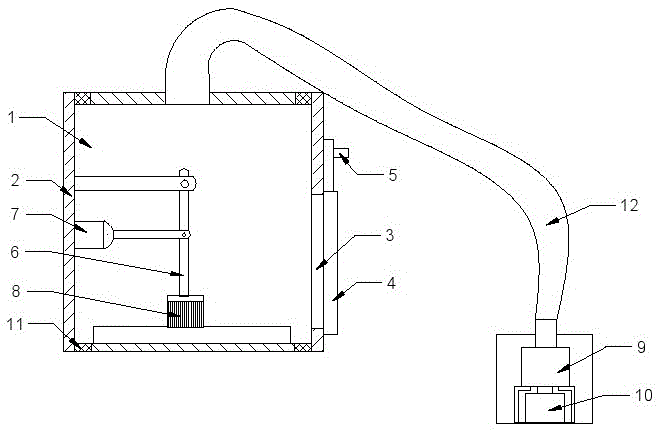

[0014] The reference signs in the drawings of the description include: dust removal box 1, mounting plate 2, opening 3, closed door 4, handle 5, support arm 6, cylinder 7, feather brush 8, fan 9, dust collection box 10, elastic member 11 , Dust removal pipeline 12.

[0015] The embodiment is basically as attached figure 1 Shown: special dust removal device for integrated circuit board, including dust removal box 1 and dust removal mechanism installed in dust removal box 1, dust removal box 1 is composed of six mounting plates 2, and adjacent mounting plates 2 are connected by elastic members 11, One side wall of the dust removal box 1 is provided with an opening 3 for the passage of the circuit board, and a chute for the sliding of the closing door 4 is provided at the opening 3 of the dust removal box 1, so that the closing door 4 slides in the chute more stably. Due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com