Preparation method of water-repellent polyester-cotton brushed fabric

A water-repellent and polyester-cotton technology, applied in fabric surface trimming, textile material treatment, plant fibers, etc., can solve the problems of affecting the fabric's aesthetics, short service life, poor waterproof performance, etc., and achieve a strong water-repellent effect , prolong the service life and shorten the fluffing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

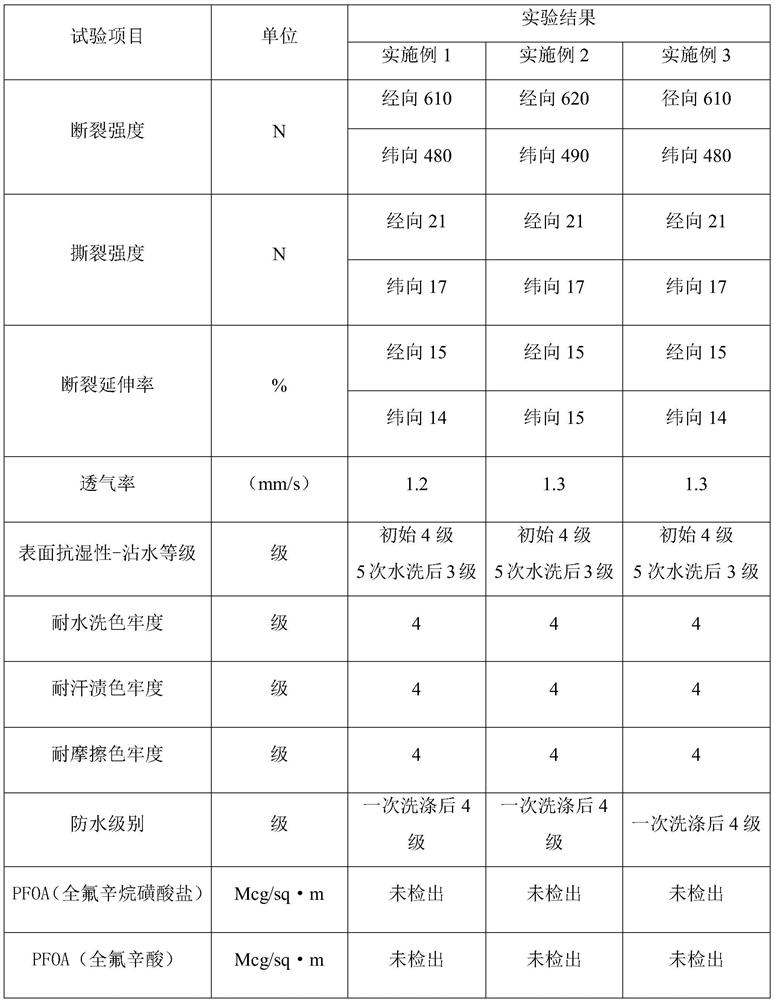

Embodiment 1

[0045] The preparation method of water-repellent polyester-cotton brushed fabric comprises the steps:

[0046] Step 1, weaving gray fabric:

[0047] The polyester-cotton blended yarn is weaved to obtain a polyester-cotton fabric, wherein the polyester-cotton blended yarn includes 65% polyester yarn and 35% cotton yarn in terms of mass percentage.

[0048] Step two, cold stack:

[0049] The polyester-cotton fabric obtained in step 1 is cold-stacked to obtain cold-stack gray fabric, the cold-stack temperature is 30°C, and the cold-stack time is 10h, wherein the cold-stack auxiliary agent includes the following components in terms of water volume: methacrylic acid shrinkage Glyceride 4g / L, caprylic capric acid macrogolglyceride 2g / L, acetic acid 2g / L.

[0050] Step three, rinse:

[0051] Rinse the cold-stacked gray cloth obtained in step 2 to obtain a rinsed cloth; during the rinsing process, the rinsing temperature is 50° C., the rinsing time is 1 h, and water is used for rin...

Embodiment 2

[0068] The preparation method of water-repellent polyester-cotton brushed fabric comprises the steps:

[0069] Step 1, weaving gray fabric:

[0070] The polyester-cotton blended yarn is weaved to obtain a polyester-cotton fabric, and the polyester-cotton blended yarn includes 70% polyester yarn and 30% cotton yarn in terms of mass percentage.

[0071] Step two, cold stack:

[0072] The polyester-cotton fabric obtained in step 1 is cold-stacked to obtain a cold-stack gray fabric, the cold-stack temperature is 33°C, and the cold-stack time is 11 hours, wherein the cold-stack auxiliary agent includes the following components in terms of water volume: methacrylic acid shrinkage Glyceride 5g / L, caprylic capric acid macrogolglyceride 3g / L, acetic acid 3g / L.

[0073] Step three, rinse:

[0074] Rinse the cold-stacked gray cloth obtained in step 2 to obtain a rinsed cloth; during the rinsing process, the rinsing temperature is 60° C., the rinsing time is 2 hours, and water is used ...

Embodiment 3

[0091] The preparation method of water-repellent polyester-cotton brushed fabric comprises the steps:

[0092] Step 1, weaving gray fabric:

[0093] The polyester-cotton blended yarn is weaved to obtain a polyester-cotton fabric, and the polyester-cotton blended yarn includes 70% polyester yarn and 30% cotton yarn in terms of mass percentage.

[0094] Step two, cold stack:

[0095] The polyester-cotton fabric obtained in step 1 is cold-stacked to obtain cold-stack gray fabric, the cold-stack temperature is 35°C, and the cold-stack time is 12h, wherein the cold-stack auxiliary agent includes the following components in terms of water volume: methacrylic acid shrinkage Glyceride 7g / L, caprylic capric acid macrogolglyceride 3g / L, acetic acid 3g / L.

[0096] Step three, rinse:

[0097] Rinse the cold-stacked gray cloth obtained in step 2 to obtain a rinsed cloth; during the rinsing process, the rinsing temperature is 65° C., the rinsing time is 2 hours, and water is used for rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com