Efficient heating mechanical hand of hot header

A high-efficiency, manipulator technology, applied in heating/cooling equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult pier forming, high hardness, waste of time, etc., to achieve flexible start and stop, small moment of inertia, Avoid inefficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

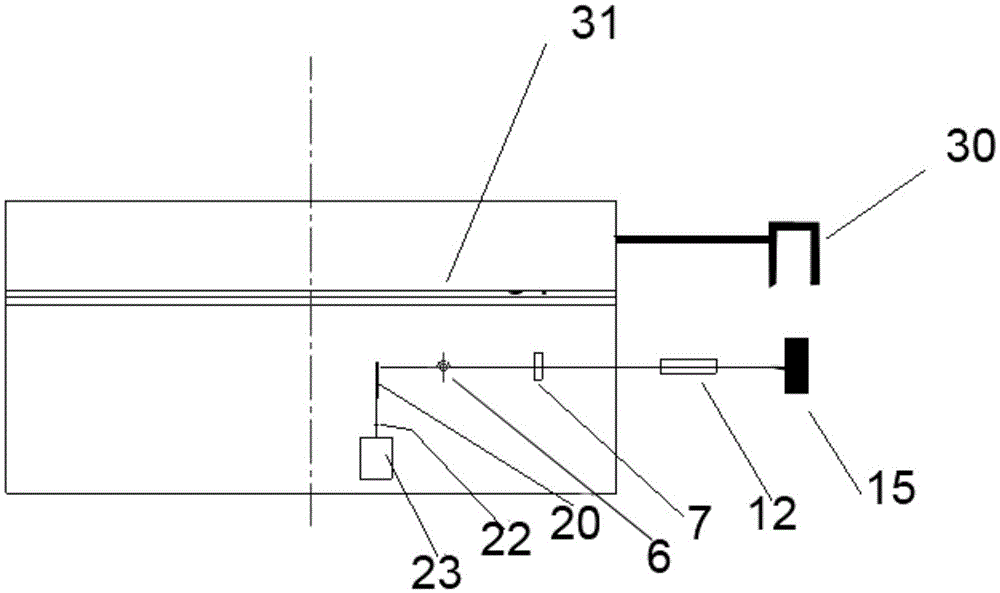

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

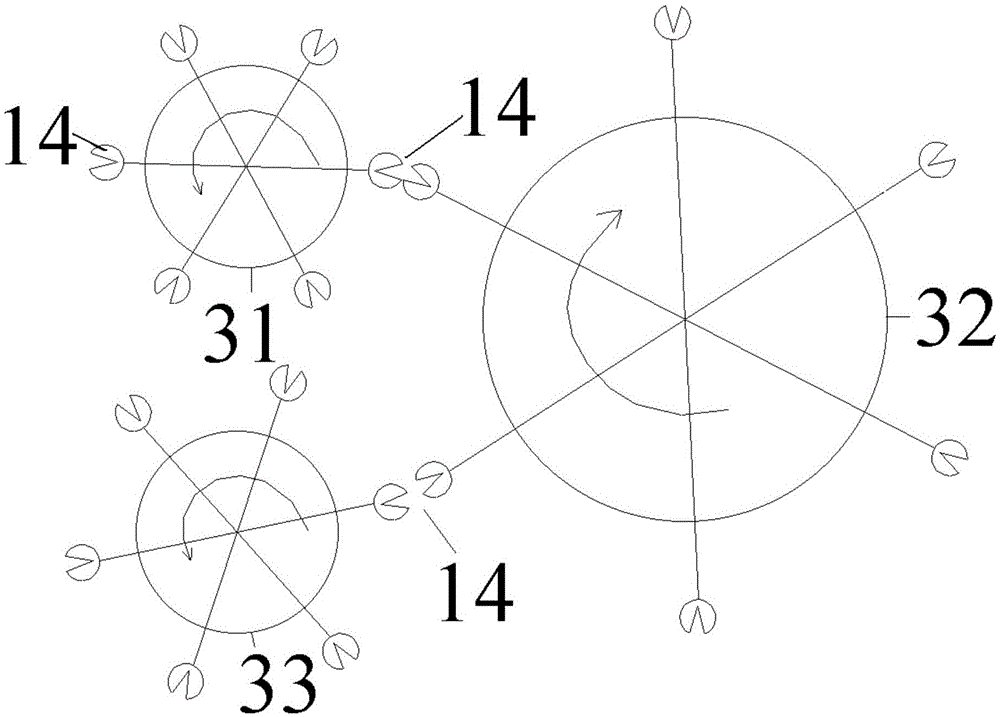

[0012] A high-efficiency heating pier machine heating manipulator, the structure is as follows Figure 1-2 As shown, it includes successively adjacent feeding turntable 32, manipulator heating turntable 33, and retrieving turntable 34. The diameter of the manipulator heating turntable 33 is much larger than the feeding turntable 32, retrieving turntable 34, feeding turntable 32, and manipulator heating turntable 33. 1. A plurality of work clamps 14 are respectively arranged on the reclaiming turntable 34 .

[0013] The feeding turntable 32, the heating turntable 33 of the mechanical arm, and the reclaiming turntable 34 are three controlled turntables. The heating turntable 33 of the mechanical arm has a large moment of inertia and keeps rotating at a constant speed. Very flexible, there is sufficient time to stop and discharge and load mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com