Method for machining narrow groove in planing mode by numerical control boring and milling machine

A boring-milling machine and narrow-slot technology, which is applied to the CNC boring-milling machine for planing and processing narrow slots, and the narrow slot machining field with circumferential radiation distribution on the gas turbine exhaust takeover heat insulation component, which can solve the problem of large diameter, high cost, and the thickness of the saw blade. Small and other problems, to ensure the quality of processing, easy operation, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

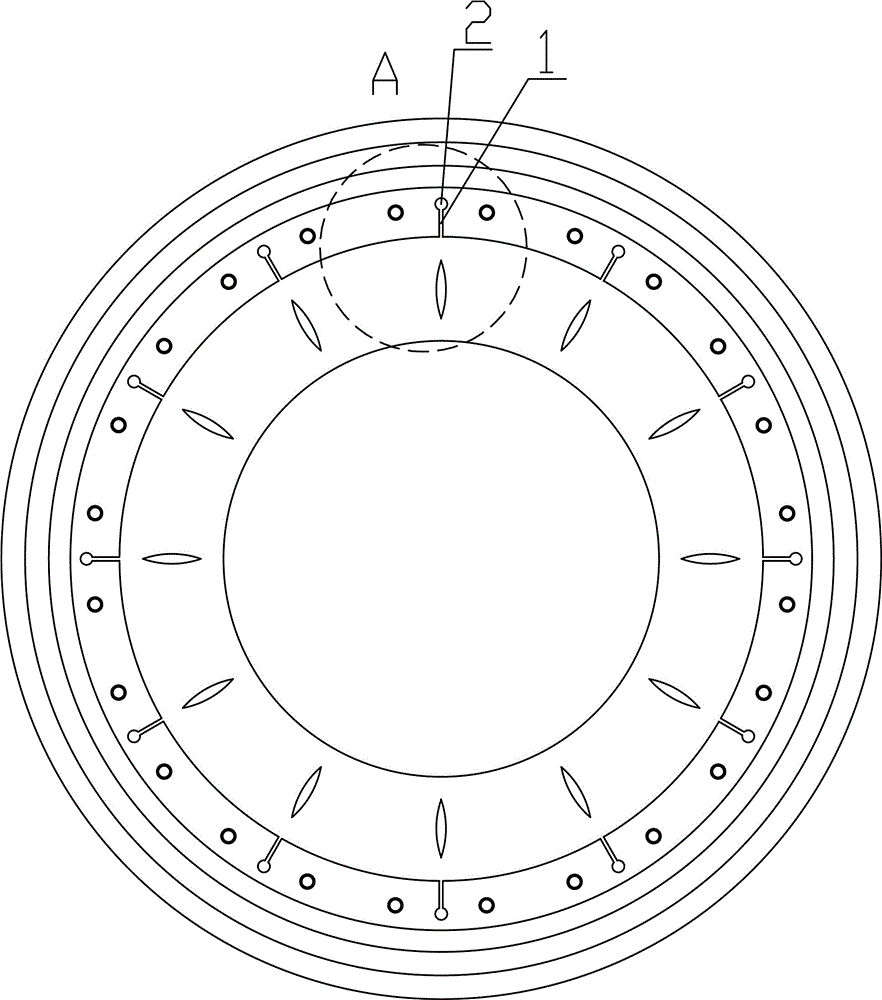

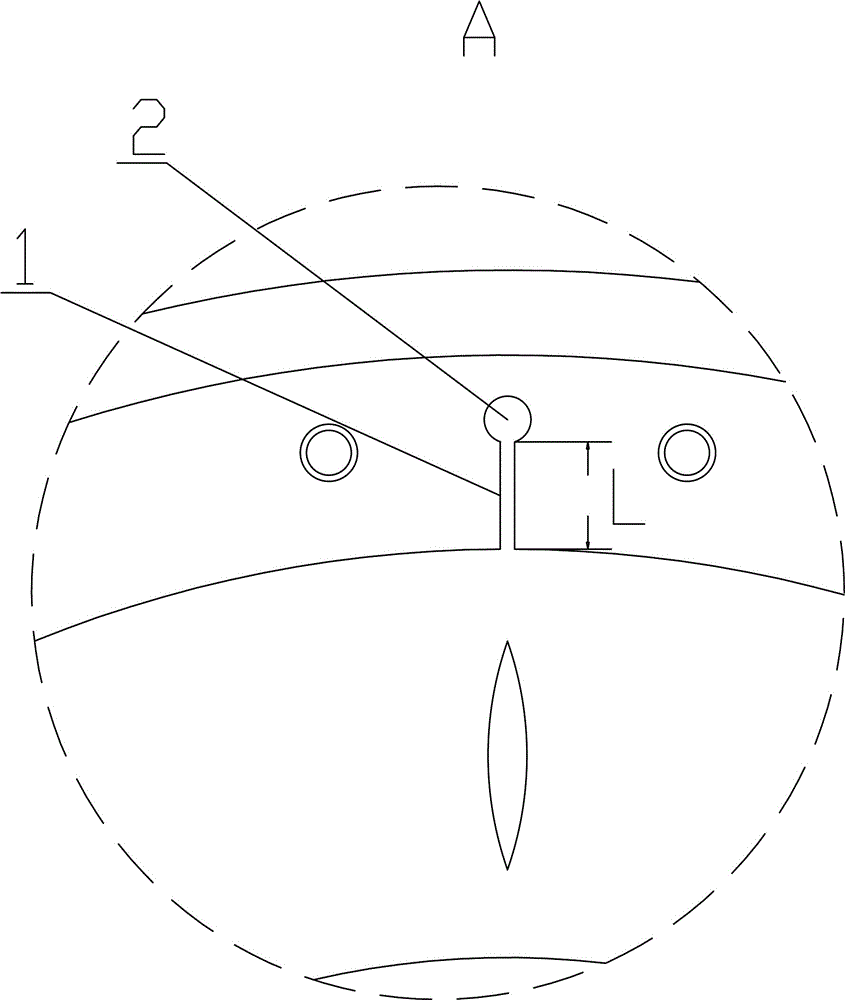

[0025] Such as Figure 1~5 Among them, a method for planing and processing narrow slots with a CNC boring and milling machine, comprising the following steps:

[0026] 1. Clamp the workpiece so that the processing surface is parallel to the main shaft 3 of the CNC boring and milling machine, and the length direction of the narrow groove 1 is parallel to the main shaft 3;

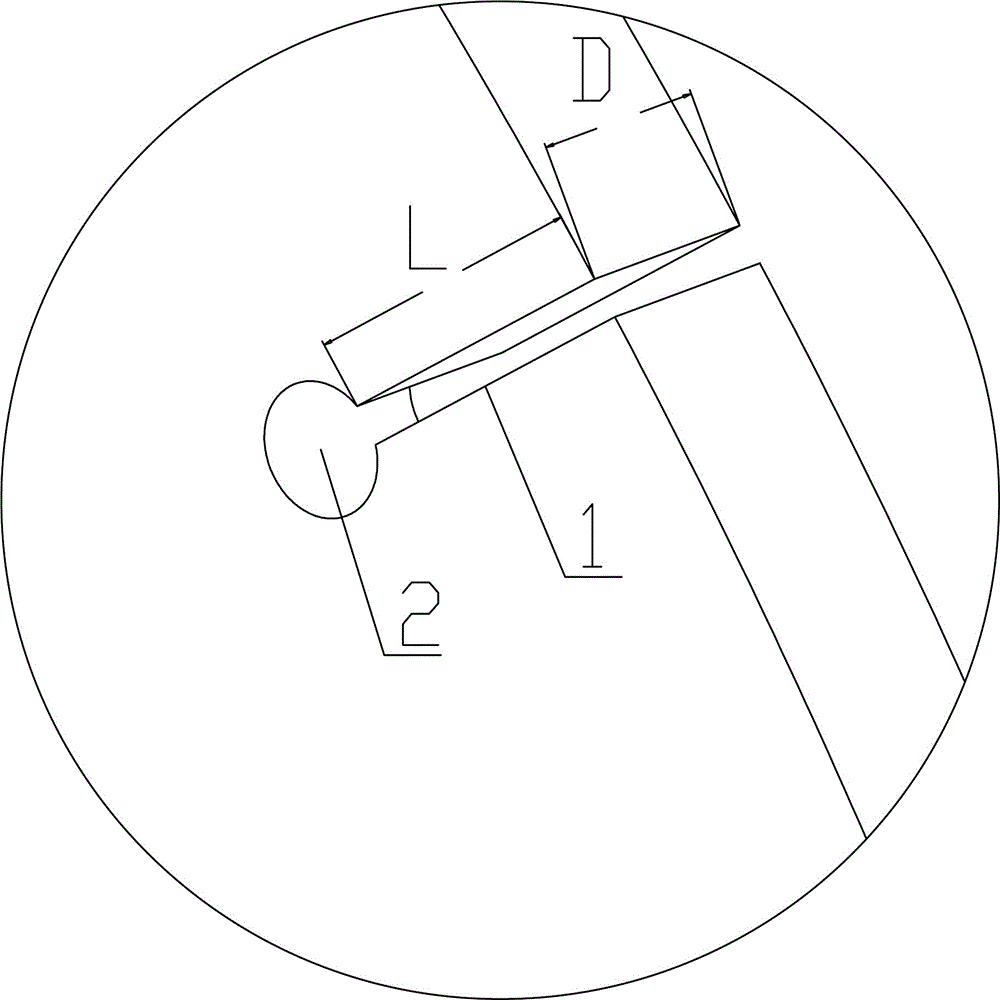

[0027] 2. Clamp and correct the tool so that the machining direction of the boring tool 6 is consistent with the length direction of the narrow slot 1, for example image 3 As shown by L in , the feeding direction is consistent with the thickness direction of the narrow groove 1, for example image 3 as shown in D;

[0028] In the preferred scheme, the boring head is installed on the CNC boring and milling machine, and the tool seat 5 of the boring head is connected with the main shaft 3, and the end face of the tool seat 5 is provided with a lower end and at least one side open knife groove 7, one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com