Real-time monitoring system and monitoring method for judging welding type of laser deep penetration welding by using high-speed camera

A real-time monitoring system, laser deep penetration welding technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the workpiece cannot be judged intuitively, and achieve the effect of advanced and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

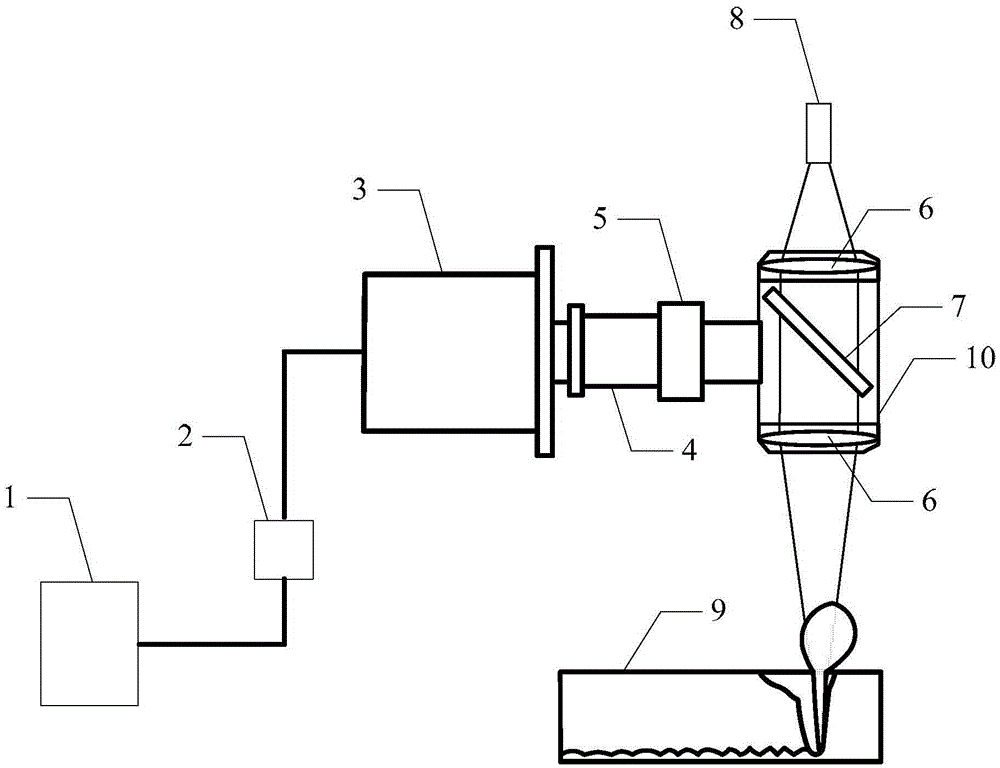

[0029] Specific implementation mode one: combine figure 1 Describe this embodiment, a real-time monitoring system that uses a high-speed camera to determine the type of laser deep penetration welding described in this embodiment, it includes an image acquisition card 2, a camera 3, a zoom lens 4, a filter system 5, two focusing Mirror 6, dichroic mirror 7, laser emitter 8 and dichroic mirror fixing frame 10;

[0030] The video signal input end of the image acquisition card 2 is connected to the video signal output end of the camera 3;

[0031] The information output end of image acquisition card 2 is connected to the information input end of PC 1; Utilize image acquisition card 2 to gather the image signal that camera 3 shoots to PC 1, save in the hard disk of PC 1 with the form of data file;

[0032] The camera 3 is used to collect images of the welding process during the laser deep penetration welding stabilization process;

[0033] The zoom lens 4 is fixed on the lens of ...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination Figure 2 to Figure 9 This embodiment is described. This embodiment is based on the monitoring method of a real-time monitoring system that uses a high-speed camera to determine the type of laser deep penetration welding described in the first embodiment. The method includes the following steps:

[0039] Step 1, start the real-time monitoring system and PC 1, after the welding process is stable, the camera 3 performs image acquisition on the welding process;

[0040] Step 2, using the PC 1 to preprocess the images collected by the camera 3;

[0041] Step 3, judge whether it is penetrating deep penetration welding according to the appearance of the keyhole and molten pool of the preprocessed image in step 2;

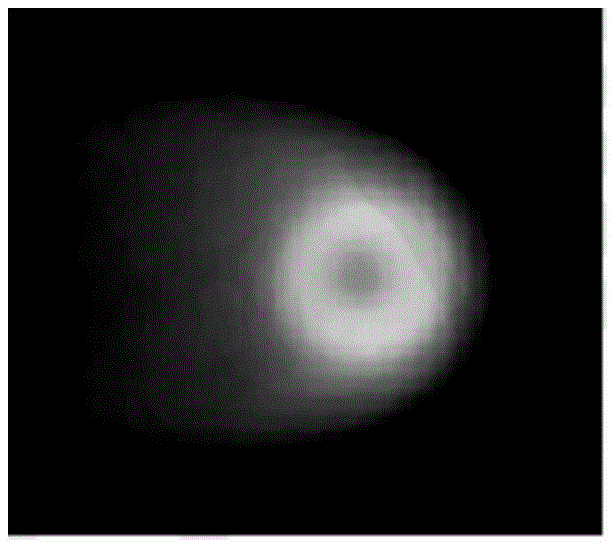

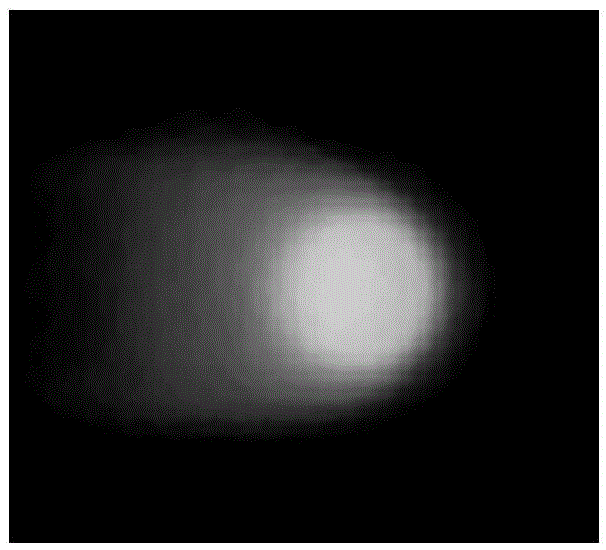

[0042] Penetrating deep penetration welding means that the weld seam is completely penetrated by the keyhole. The form of penetrating deep penetration welding in the image is: the shape of the keyhole is two circles, t...

specific Embodiment approach 3

[0045] Specific embodiment three: this embodiment is to explain the monitoring method of a real-time monitoring system that uses a high-speed camera to determine the type of laser deep penetration welding described in specific embodiment two. In this embodiment, PC 1 The method of preprocessing the image collected by camera 3 is as follows:

[0046] Method A: Median smoothing filter to remove noise;

[0047] Method B: homomorphic filtering;

[0048] Method C: Linear grayscale transformation image enhancement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com