Film processor

A technology of membrane processor and roll-type membrane, which is applied in the field of water purification, can solve the problems of water production waste, large water production, consumption, etc., and achieve the effect of reducing water production and reducing water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

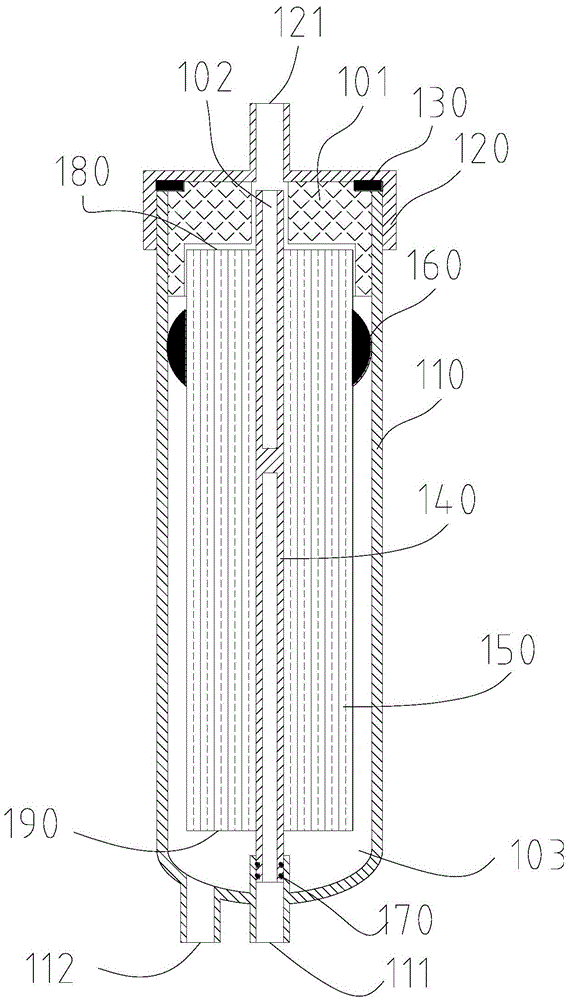

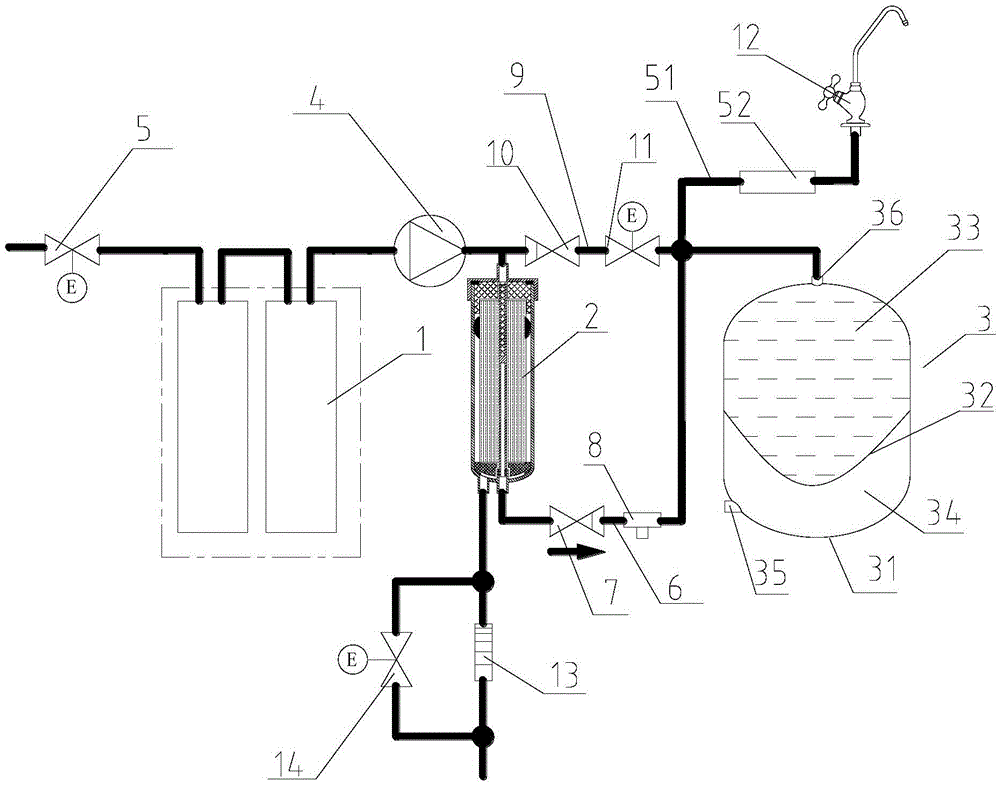

[0022] like figure 1 As shown, it is a schematic structural diagram of a membrane processor provided by the present invention, and the membrane processor includes: a housing 110 , a cover 120 and a roll-type membrane module. A first sealing ring 130 is disposed between the cover body 120 and the housing 110 . The cover 120 is provided with a water inlet 121 . The casing 110 is provided with a produced water outlet 111 and a concentrated water outlet 112 . The roll-type membrane assembly is arranged inside the casing 110. The roll-type membrane assembly includes a core tube 140 and a diaphragm group 150 wound on the core tube 140. The diaphragm group 150 includes a plate-shaped membrane, a raw water diversion net and a produced water diversion The space where the raw water diversion net is located is the raw water flow channel, and the space where the water production diversion net is located is the water production channel. The outer side of the diaphragm group 150 is also p...

Embodiment 2

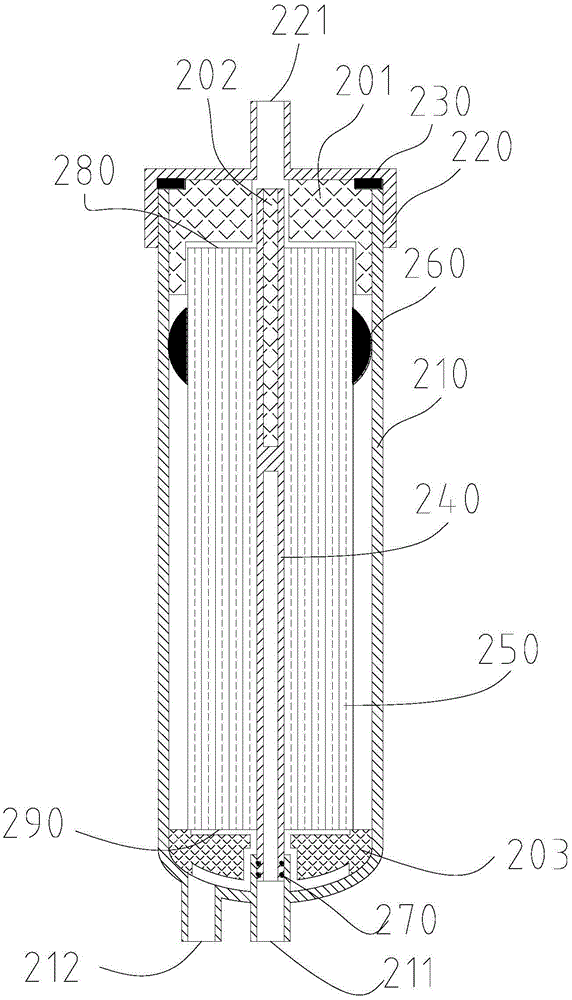

[0025] like figure 2 As shown, it is a schematic structural diagram of a membrane processor provided by the present invention, and the membrane processor includes: a housing 210 , a cover 220 and a roll-type membrane module. A first sealing ring 230 is disposed between the cover body 220 and the housing 210 . The cover 220 is provided with a water inlet 221 . The casing 210 is provided with a produced water outlet 211 and a concentrated water outlet 212 . The coiled membrane module is arranged inside the housing 210. The coiled membrane module includes a core tube 240 and a diaphragm group 250 wound on the core tube 240. The diaphragm group 250 includes a plate-shaped membrane, a raw water diversion net and a produced water diversion The space where the raw water diversion net is located is the raw water flow channel, and the space where the water production diversion net is located is the water production channel. The outer side of the diaphragm group 250 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com