A method of preparing components of railroad engineering machine-made sand pump concrete

A technology for pumping concrete, railway engineering, applied in the field of concrete, can solve problems such as not grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

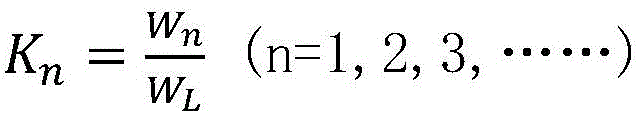

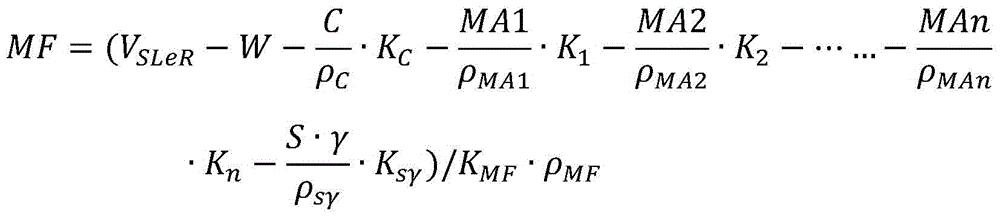

Method used

Image

Examples

Embodiment 1

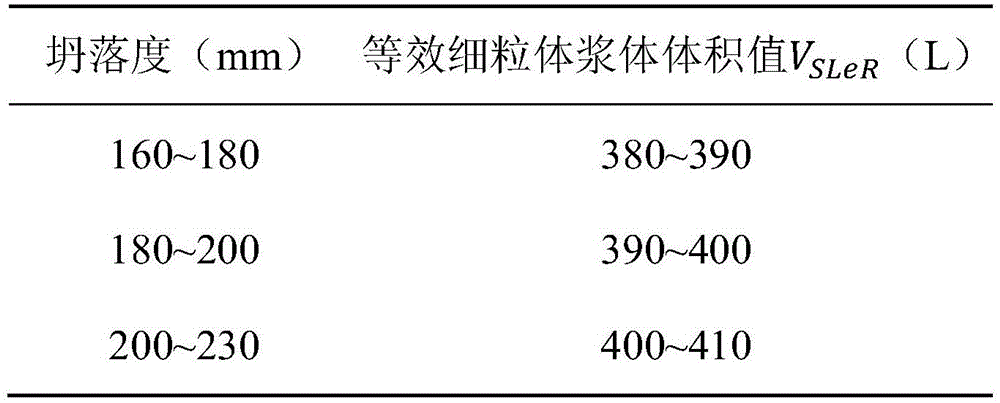

[0051] Example 1: C25 machine-made sand pumping concrete, σ is 5.0MPa, and the required slump is 180-200mm.

[0052] The use of raw materials in the following implementation is as follows: Sichuan Esheng Cement Co., Ltd. P.O42.5 ordinary Portland cement, density 3.10g / cm 3 ; Sichuan Juxing New Material Co., Ltd. JX-GBNHy2 high-performance polycarboxylate superplasticizer, the recommended dosage is 0.8%; Suining thermal power plant Ⅱ grade fly ash, density 2.45g / cm 3 , 14.6% fineness, 25% internally mixed; burnt clay from Sichuan Donglanxing Technology Development Co., Ltd., with a density of 2.65g / cm 3 , mixed with 5%; Guanghan machine-made sand, fineness modulus 2.67, apparent density 2680kg / m 3 , the loose bulk density is 1450kg / m 3 ; The content of fine grains (particles less than 0.15mm) in the sand is 12.0%, and the density is 2.7g / cm 3 ; 5 ~ 25mm continuous gravel, the apparent density is 2680kg / m 3 , loose bulk density 1530kg / m 3 , the porosity is 43%, and the crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com