Process for making cyclohexanone

A technology of cyclohexanone and cyclohexylbenzene, which is applied in the field of cyclohexanone manufacturing, can solve the problems of non-challenge and yield loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

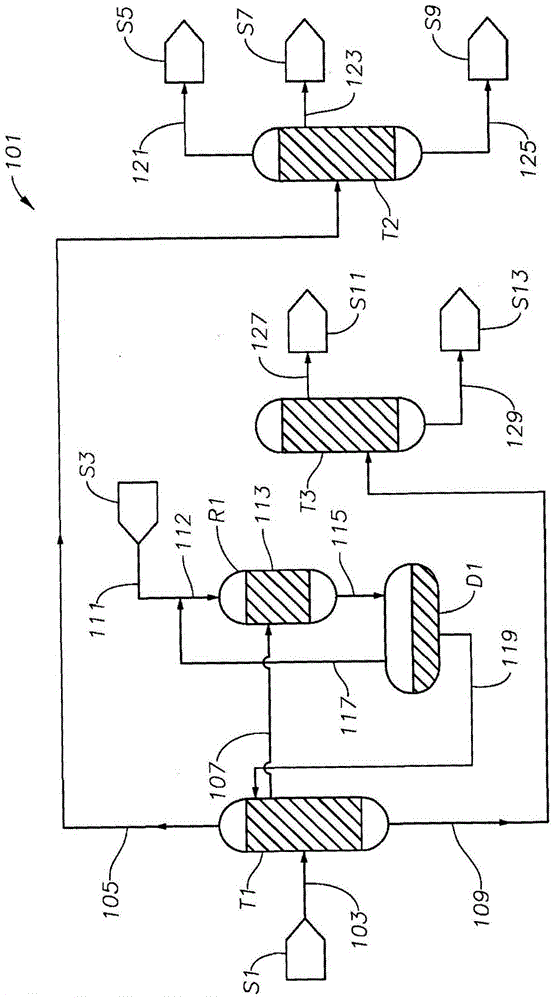

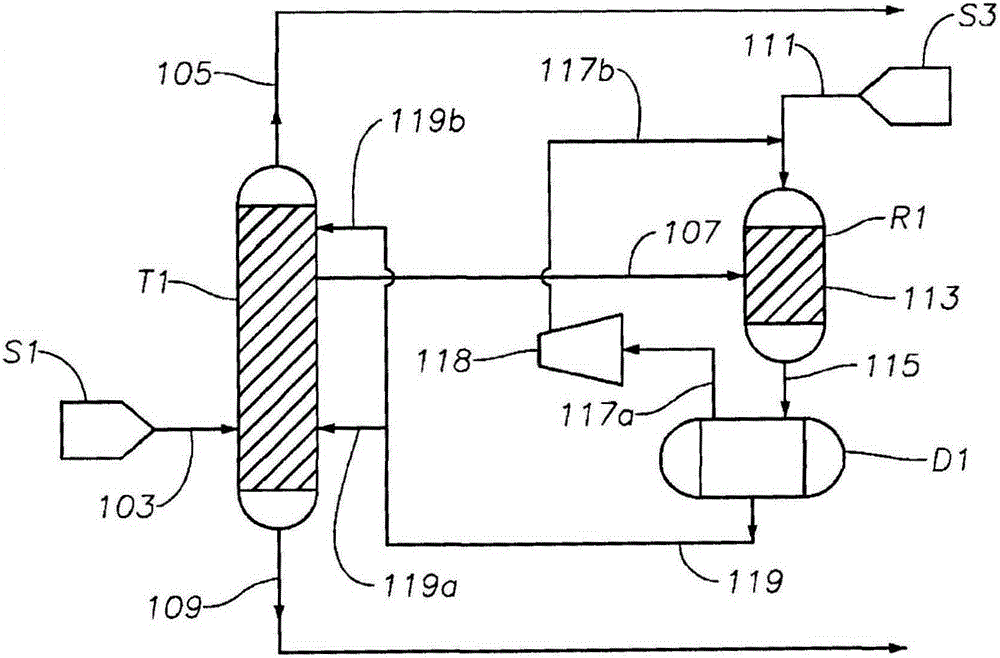

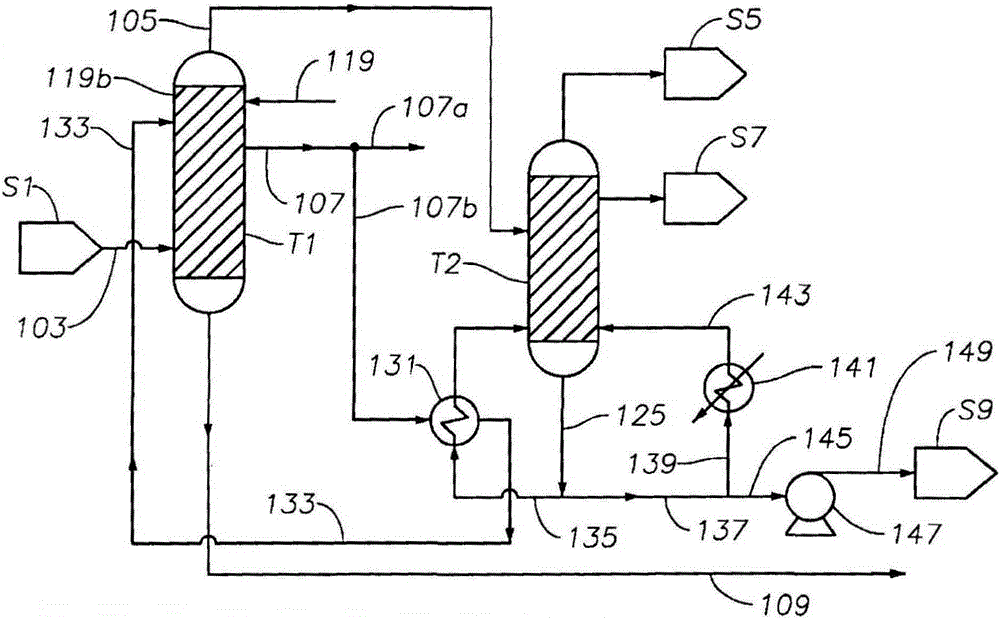

[0191] E1. a method for manufacturing cyclohexanone, the method may further comprise the steps:

[0192](1) the first mixture containing cyclohexanone, phenol, and cyclohexylbenzene is fed into the first distillation column;

[0193] (II) obtain from the first distillation column:

[0194] a first upper effluent comprising phenol, cyclohexylbenzene, and cyclohexanone at a concentration higher than that of the first mixture;

[0195] A first intermediate effluent comprising cyclohexanone, cyclohexylbenzene, bicyclohexane produced in step (III) below, and phenol at a concentration higher than in the first mixture; and

[0196] a first lower effluent comprising cyclohexylbenzene at a higher concentration than in the first mixture;

[0197] (III) at least a part of the first intermediate effluent and hydrogen are fed into the hydrogenation reaction zone, wherein under hydrogenation reaction conditions, in the presence of a hydrogenation catalyst, phenol is reacted with hydrogen,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com