Rubber

A technology of rubber and rubber anti-aging agent, which is applied in the field of rubber to achieve significant damping and heat generation effects, good strength and viscoelastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Rubber X1

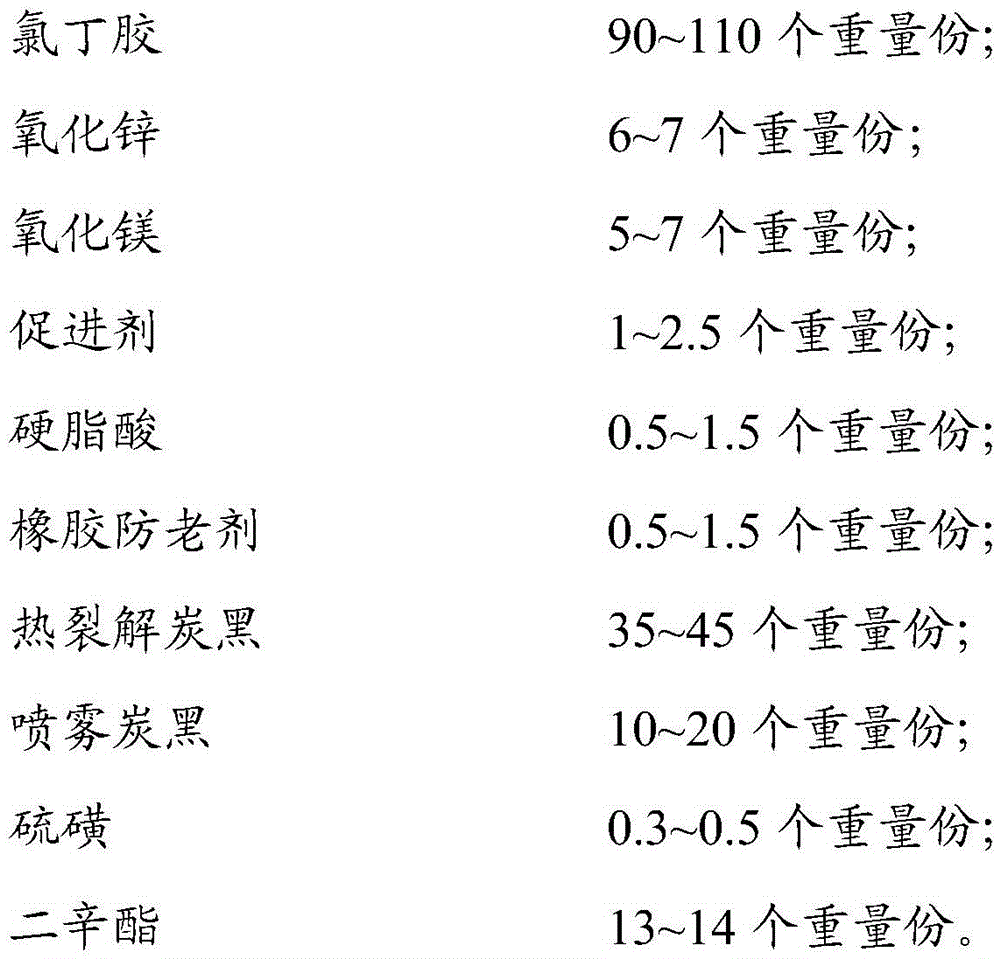

[0023] Specifically include the following components and component content:

[0024]

[0025]

[0026] Example 2 Rubber X2

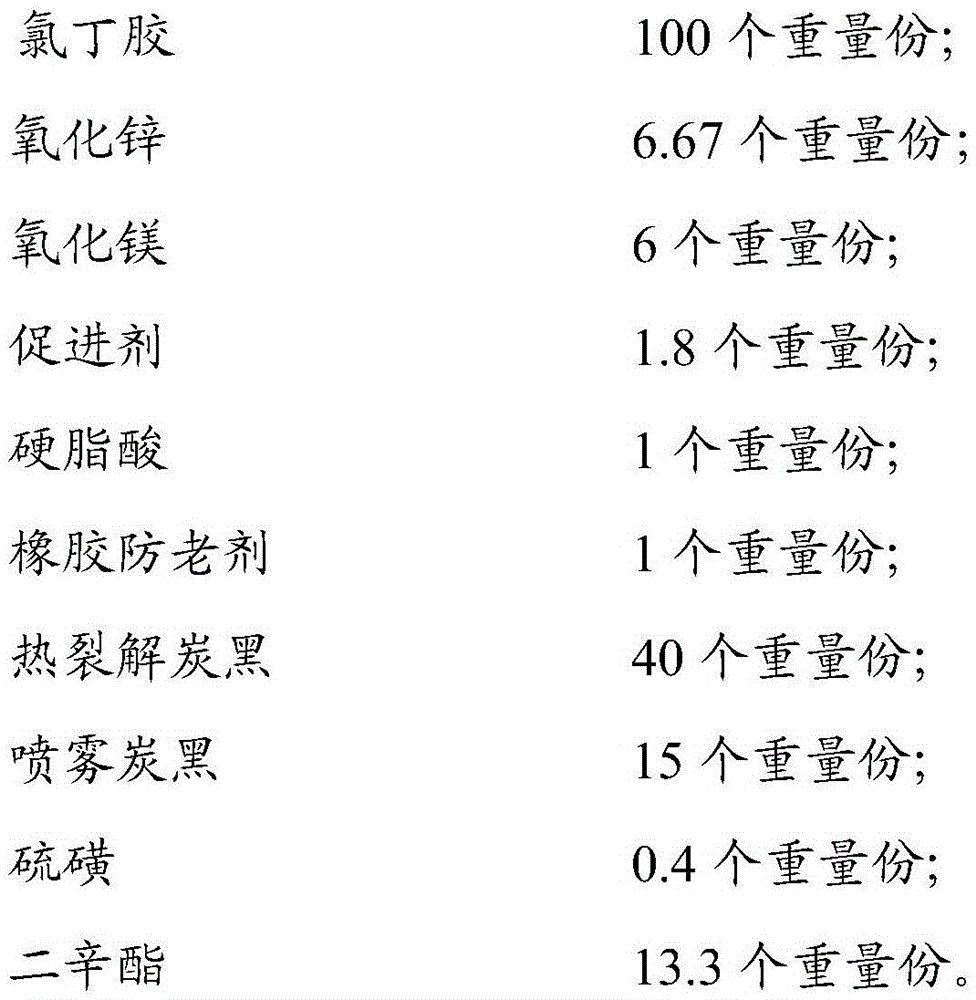

[0027] Specifically include the following components and component content:

[0028]

[0029] Example 3 Rubber X3

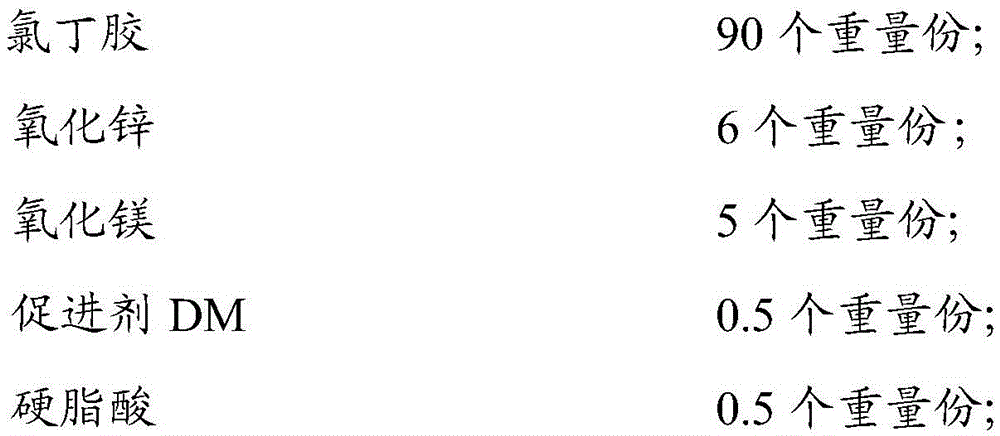

[0030] Specifically include the following components and component content:

[0031]

[0032]

[0033] Embodiment 4 Rubber X4

[0034] Specifically include the following components and component content:

[0035]

Embodiment 5

[0036] Embodiment 5 Rubber X5

[0037] Specifically include the following components and component content:

[0038]

[0039]

[0040] Embodiment 6 Rubber X6

[0041] Specifically include the following components and component content:

[0042]

[0043] Wherein, the composition and component content of the rubber of the present invention can also be expressed in a table, specifically:

[0044]

[0045]

[0046] The manufacturing method of the rubber of the present invention is as follows: put the constituent components of each component content into a kneader for kneading, wherein the kneading temperature is 50-60° C., and the kneading time is 20 minutes.

[0047] The rubbers X1 to X6 of Examples 1 to 6 of the present invention were submitted for inspection, and compared with ordinary rubber, it can be seen that they are quite different in the following aspects, specifically as The table below Show:

[0048]

[0049] by the above in the table It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com