Particle impact noise detection analyzer

A technology of noise detection and particle collision, applied in the field of mechatronics, can solve problems such as the inability to meet the requirements of testing and analysis, and achieve the effect of ensuring signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

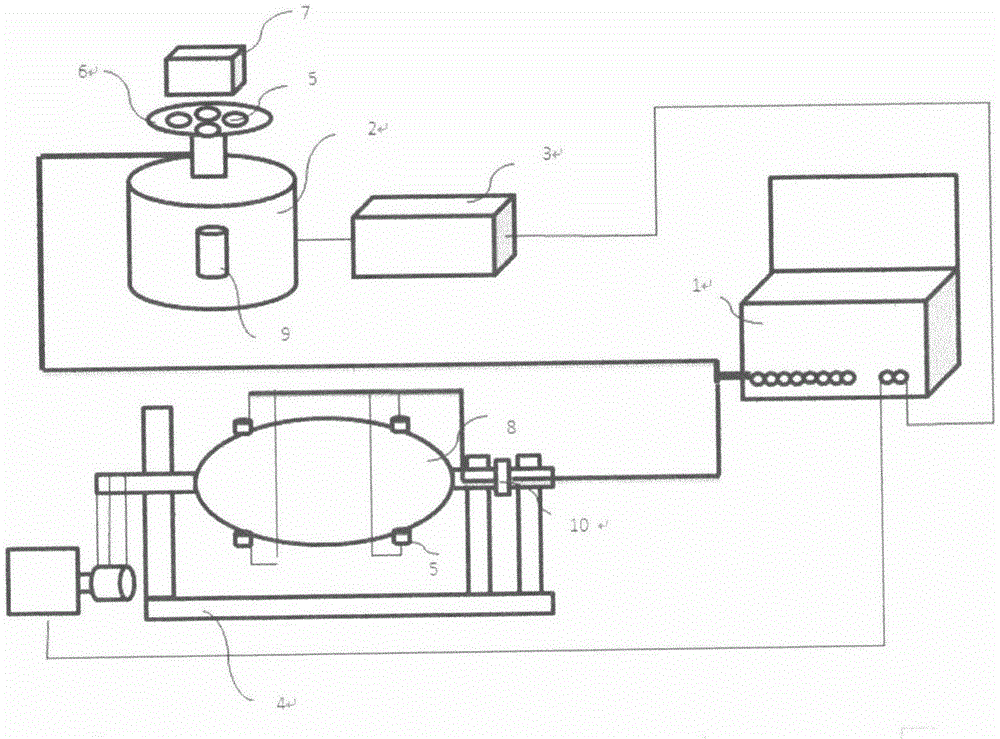

[0038] 1. The 16-channel input and 2-channel output acquisition control circuit (expandable) is integrated into the host computer with PC function through PCI bus (or PXI, USB) communication form.

[0039] 2. Use matlab (vb, c or labview) to program the driver and operating software.

[0040] 3. Design the independent power amplifier system with power and have a large thrust vibration table (0-3 tons). The vibration table adopts an integrated impact device to achieve a high impact of 1000g.

[0041] 4. Design and manufacture the turntable with independent motor drive, and the signal transmission adopts the form of slip ring or winding device.

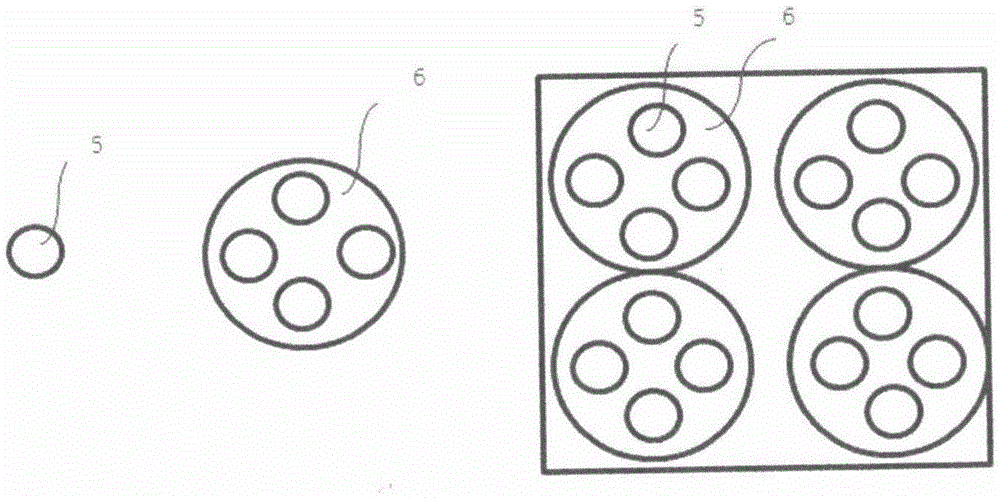

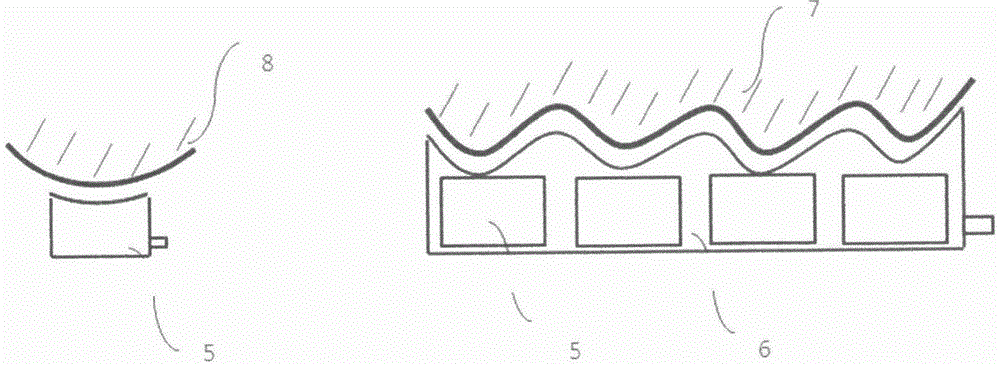

[0042] 5. Design and manufacture single-point high-sensitivity particle acoustic sensors, and sensor integrated modules (divided into plane general design and curved surface flexible design.

[0043] 6. Components are connected to the chassis integration, and the appearance design of the internal components of the instrument.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com