Full-automatic lamp tube assembly machine of T8 LED lamp tube full-automatic production line

A fully automatic, production line technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high loss, low production efficiency, low product quality qualification rate, etc., and achieve the effect of high cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

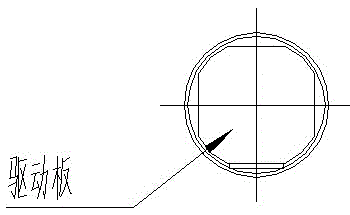

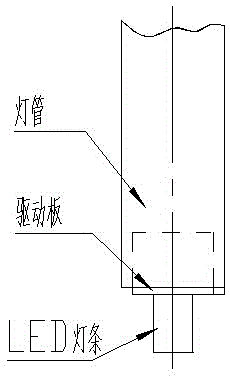

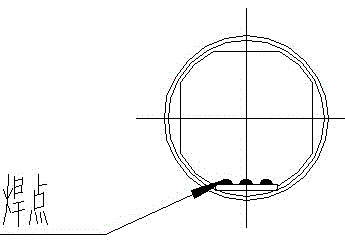

[0037]The structure of the T8 LED tube automatic production line lamp pressing machine is shown in the figure: including frame 1, mechanical transmission device 2, lamp fixture 3, lamp automatic positioning plate 4, light bar automatic positioning plate 5, light bar detection device 6. Lamp tube rotating manipulator 7, gap divider 8, station indexing plate 9, drive plate fixture 10, drive plate manipulator longitudinal control cylinder 11, drive plate manipulator longitudinal moving track 12, drive plate manipulator up and down control cylinder 13, drive Plate manipulator moving track up and down 14, drive plate manipulator control cylinder 15, drive plate manipulator 16, drive plate lamp tube clamping device 17, lamp tube clamping device control cylinder 18, automatic welding control box 19, automatic welding device 20, automatic welding Drive plate clamping manipulator 21, automatic welding drive plate clamping device 22, automatic welding lamp tube clamping device 23, automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com