Swing polishing device for complex curved surface polishing machining

A polishing device and technology for complex curved surfaces, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as difficulty in satisfying complex curved surface polishing, and obvious leftovers on the machined surface of workpieces, so as to improve workpiece life and improve The effect of surface accuracy and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] See Figure 1a-Figure 6 , the embodiment of the present invention is described below in conjunction with accompanying drawing.

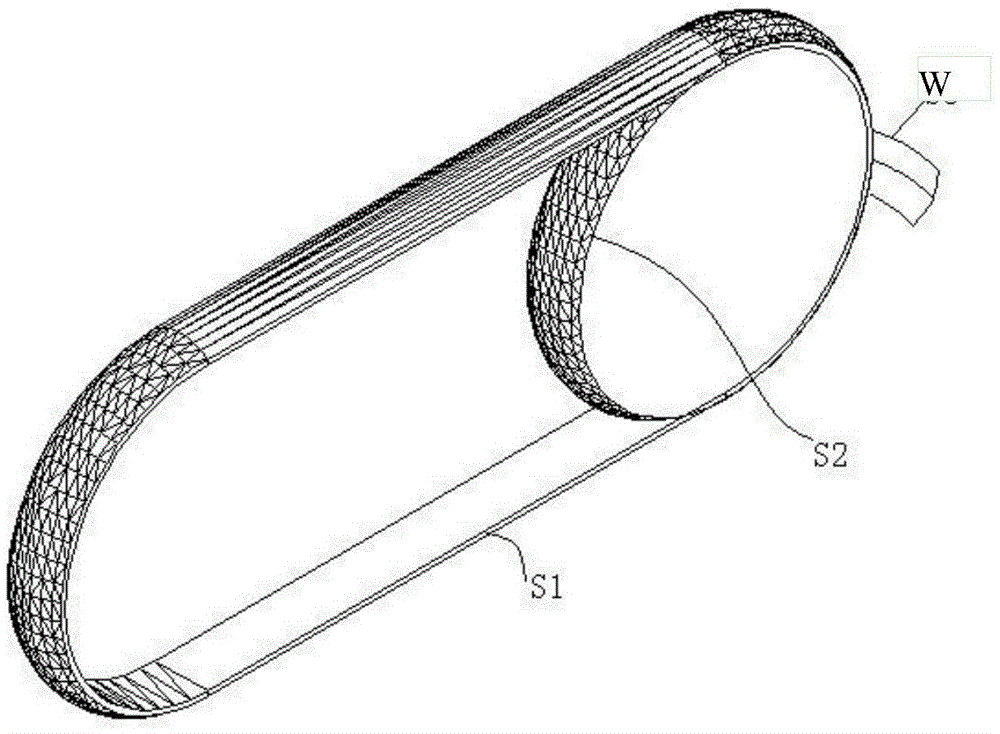

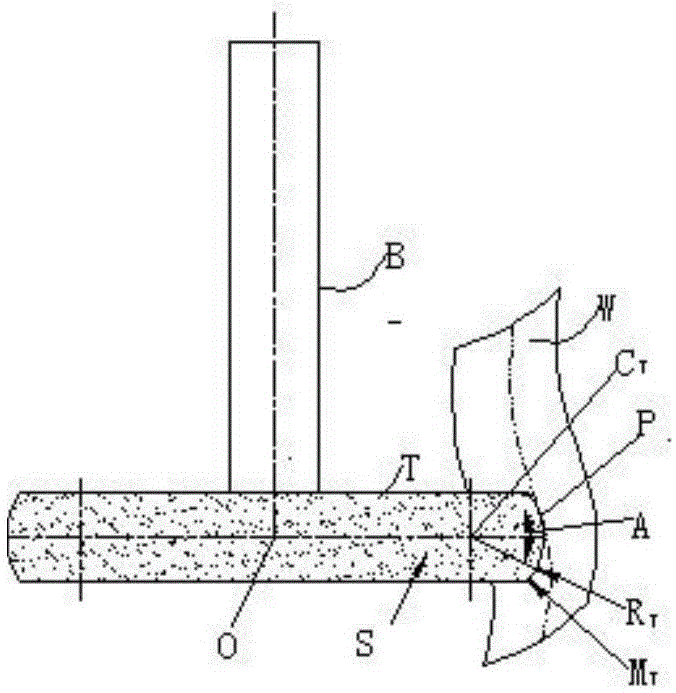

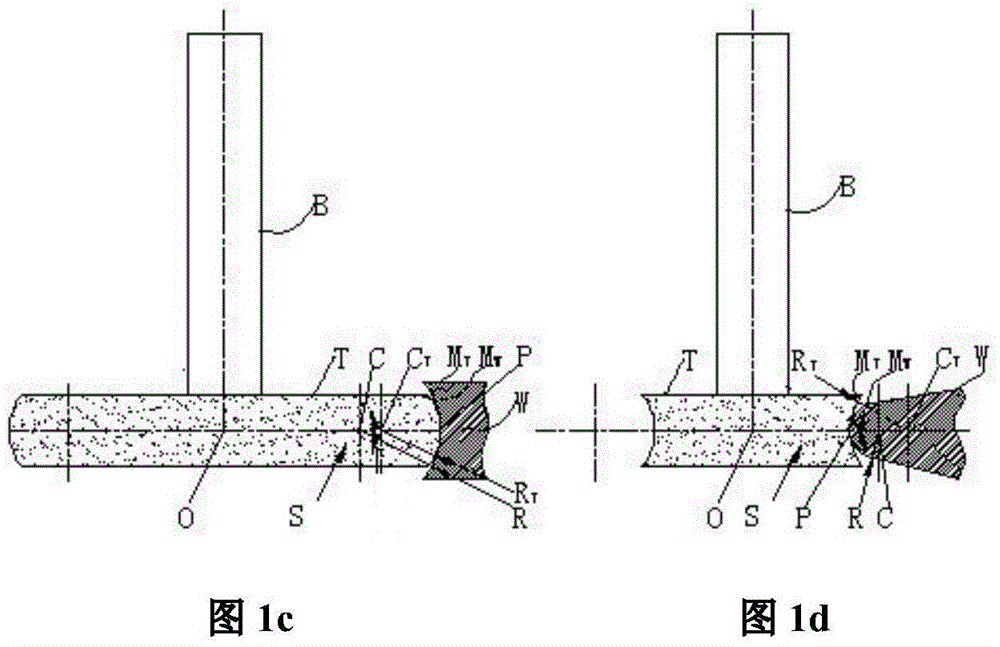

[0025] Figure 1c , 1d is a specific embodiment of grinding and polishing complex curved surfaces based on the polishing wheel of the swing mechanism. in Figure 1c The convex busbar polishing wheel is used to polish the concave surface. The drum-shaped polishing wheel itself follows the main shaft and moves around the center of rotation O. According to the curvature radius W of the concave surface of the workpiece W r Adjust the swing motion A to make the tool T swing around the center of the transition arc of the workpiece W, so that the abrasive grain S generates a fluctuating track on the curved surface of the workpiece, and changes the horizontal knife pattern with a single direction into random patterns along all directions. This trajectory can improve the processing line width and ensure the consistency of surface processing quality....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com