Weighing and weight losing integrated extrusion control system and method

A control system and integrated technology, applied in the field of weighing and weight loss integrated extrusion control system, can solve the problems of short service life of extruder screw, inaccurate raw material ratio, unstable product output, etc., to solve the problem of output decline , improve quality, improve accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

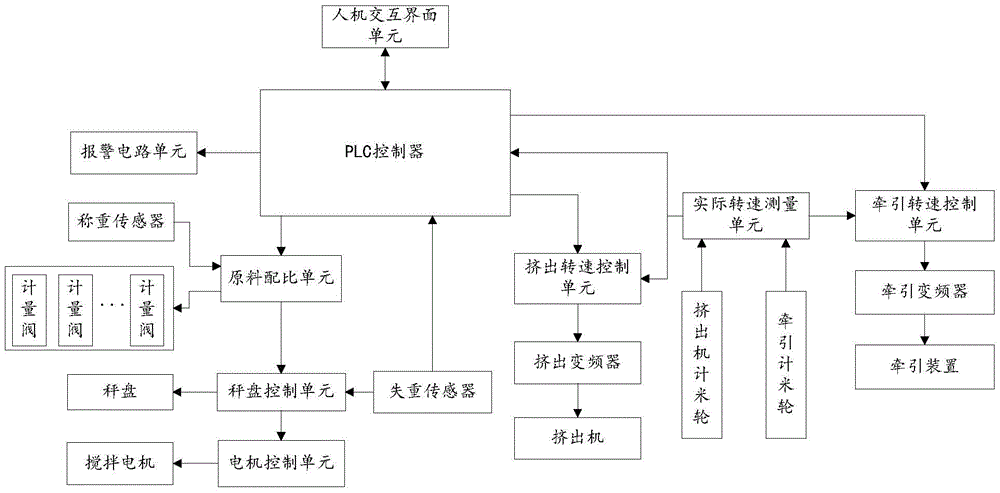

[0028] Embodiment 1. A weight loss integrated extrusion control system. Combine below figure 1 The system provided by the present invention is described in detail.

[0029] see figure 1 , the system provided by the present invention includes a human-computer interaction unit, a PLC controller, a raw material proportioning unit, a weighing pan control unit, a motor control unit, an extrusion speed control unit, a traction speed control unit, an alarm circuit unit, a storage tank, a metering Valves, weighing pans, load cells, loss-in-weight buckets, loss-in-weight sensors, stirring motors, extruders, traction units, extrusion drives and traction frequency converters.

[0030] There are multiple storage tanks, each storage tank stores a kind of raw material, and the multiple storage tanks correspond to a plurality of metering valves, and each metering valve is installed at the bottom of the corresponding material storage tank. The weighing pan is located directly below the plu...

Embodiment 2

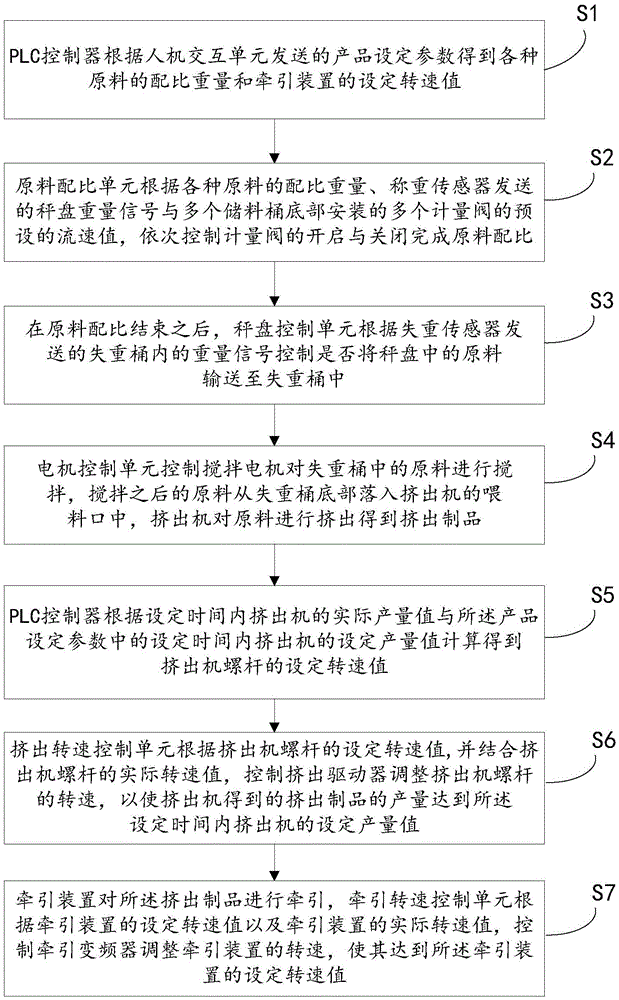

[0053] Embodiment 2. A weight loss integrated extrusion control method. Combine below figure 2 The method provided by the present invention is described in detail.

[0054] see figure 2 , S1. The PLC controller obtains the proportioning weight of various raw materials and the set speed value of the traction device according to the input product setting parameters, and sends the proportioning weight of the various raw materials to the raw material proportioning unit, and sends The set speed value of the traction device is sent to the traction speed control unit, wherein the product set parameters at least include the set output value of the extruder within a set time.

[0055] Specifically, the human-computer interaction unit inputs product setting parameters to the PLC controller, and the product setting parameters at least include the set output value of the extruder within the set time, and the PLC controller sets the parameters according to the product Obtain the propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com