Full-automatic feeding and discharging mechanism for freeze-drying tablet production equipment

A technology for production equipment, material feeding and discharging, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased risk of drug contamination, uncontrollable personnel errors, short duration, etc., and achieve unmanned feeding and discharging. , save labor costs, and ensure the effect of sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

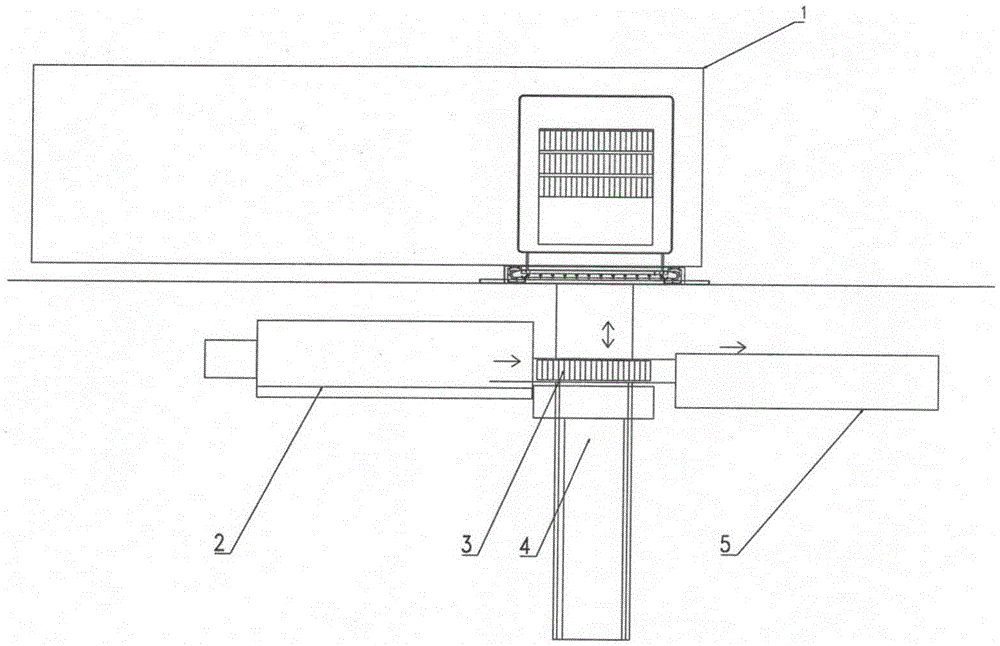

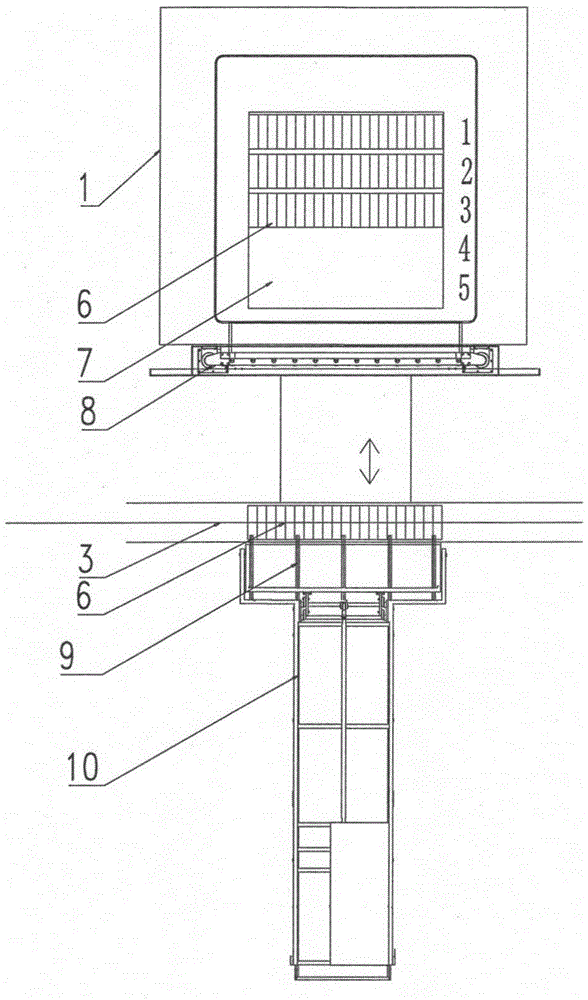

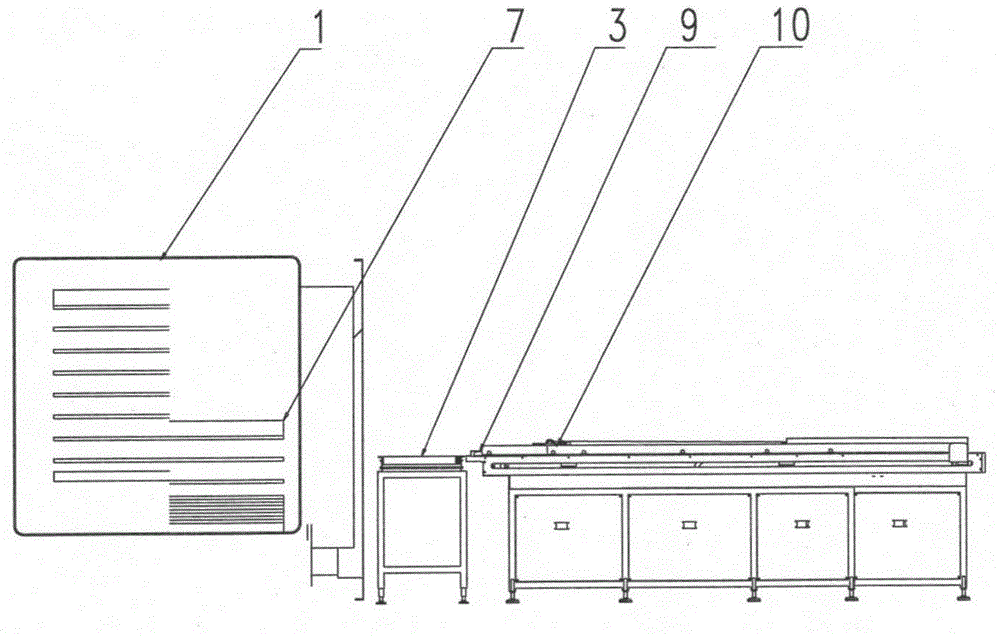

[0024] figure 1 The overall schematic diagram of the fully automatic feeding and discharging mechanism for freeze-dried tablet production equipment provided in this embodiment, the fully automatic feeding and discharging mechanism for freeze-dried tablet production equipment includes a conveying chain plate device 3 and an automatic feeding and discharging device 4, conveying The starting end of the chain plate device 3 is connected to the liquid nitrogen quick-freezing forming machine 2, and the film-coated packaging machine 5 is located at the end of the conveying chain plate device 3; the freeze dryer 1 is located on the side of the conveying chain plate device 3, and the automatic feeding and discharging device 4 is located in the conveying chain plate device 3 On the other side, the freeze dryer 1 and the automatic feeding an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com