Full-automatic correction and force measurement machine for carbon brush springs

A force measuring machine, fully automatic technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of high cost, low detection efficiency, low measurement accuracy, etc., and achieve low manufacturing cost and force measurement efficiency High, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

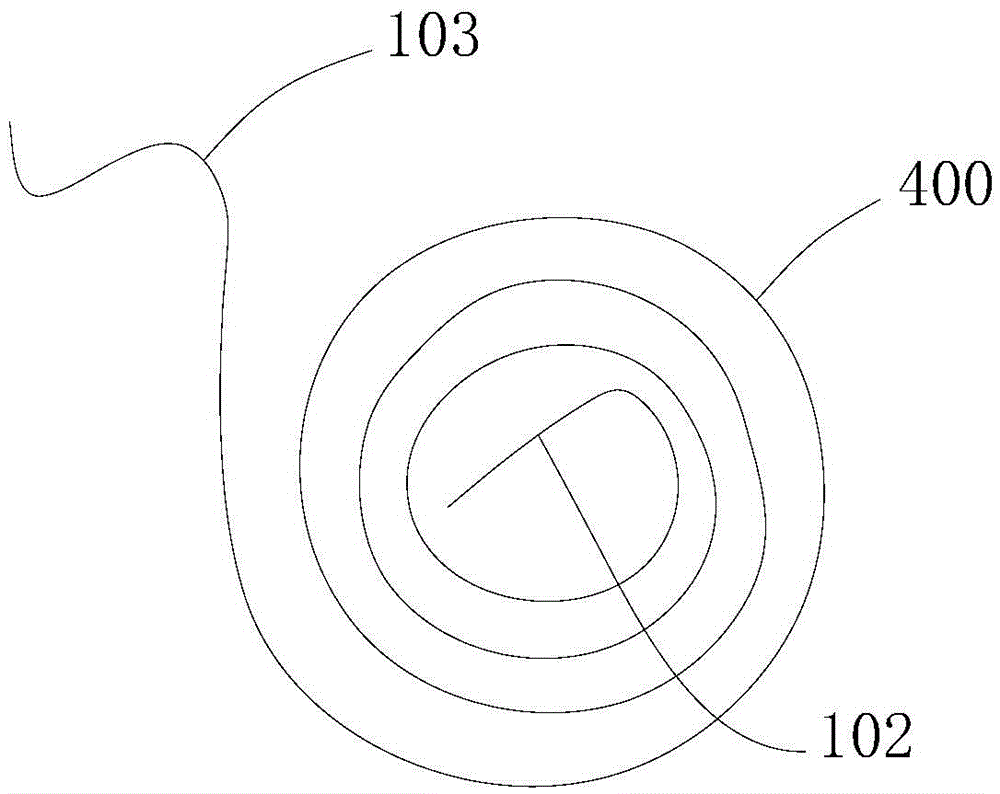

[0033] The carbon brush spring controls the force very accurately during use, and it needs to be tested before use to meet the use requirements. The existing technology uses manual force measurement. Manual force measurement has low efficiency, inaccurate detection and high cost.

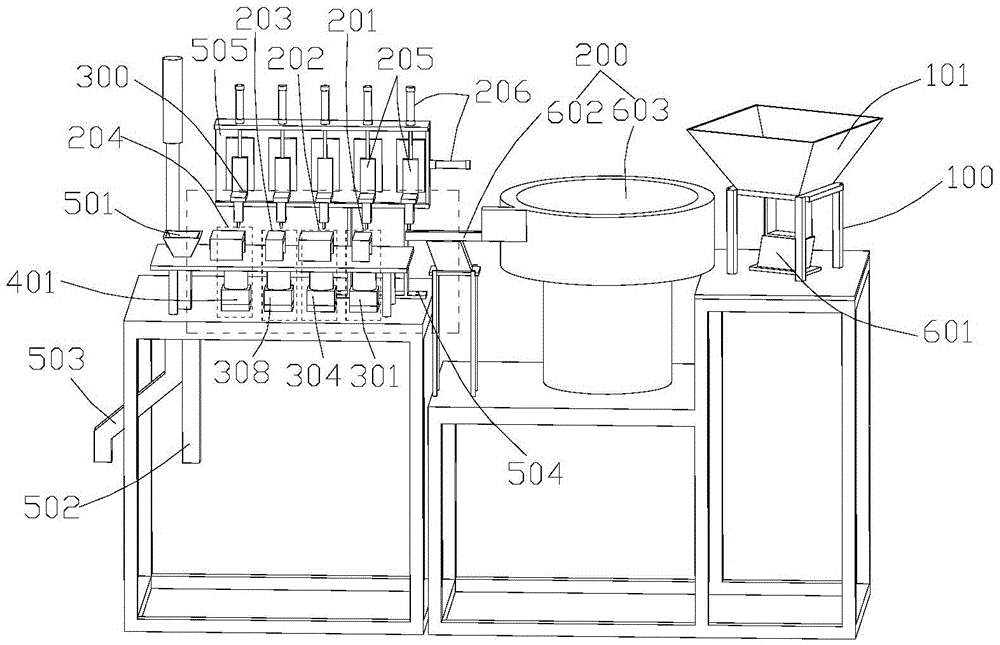

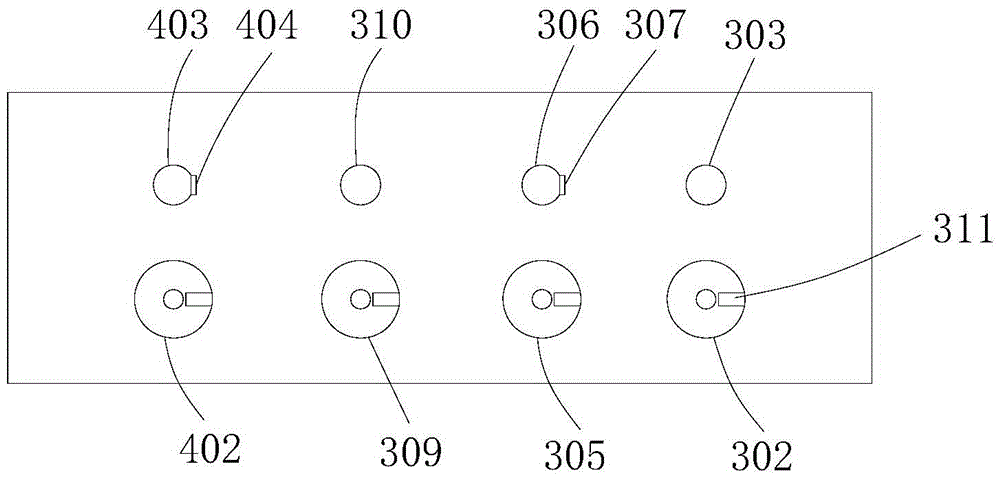

[0034] In view of this, the designer of the present invention has designed a kind of full-automatic carbon brush spring correction dynamometer, and this correction dynamometer structure is simple and reasonable, and processing is convenient; The carbon brush spring is transported to the calibration area, the force measurement area and the calibration area in sequence by the manipulator, and the force measurement process of the carbon brush spring is completed. The force measurement efficiency of the carbon brush spring is high, the precision is high, and the cost is saved.

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com