Pure water manufacturing equipment

A technology for manufacturing equipment and pure water, which is applied in water treatment parameter control, water/sewage treatment, non-polluted water treatment, etc., to achieve good backwashing effect, good water quality and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

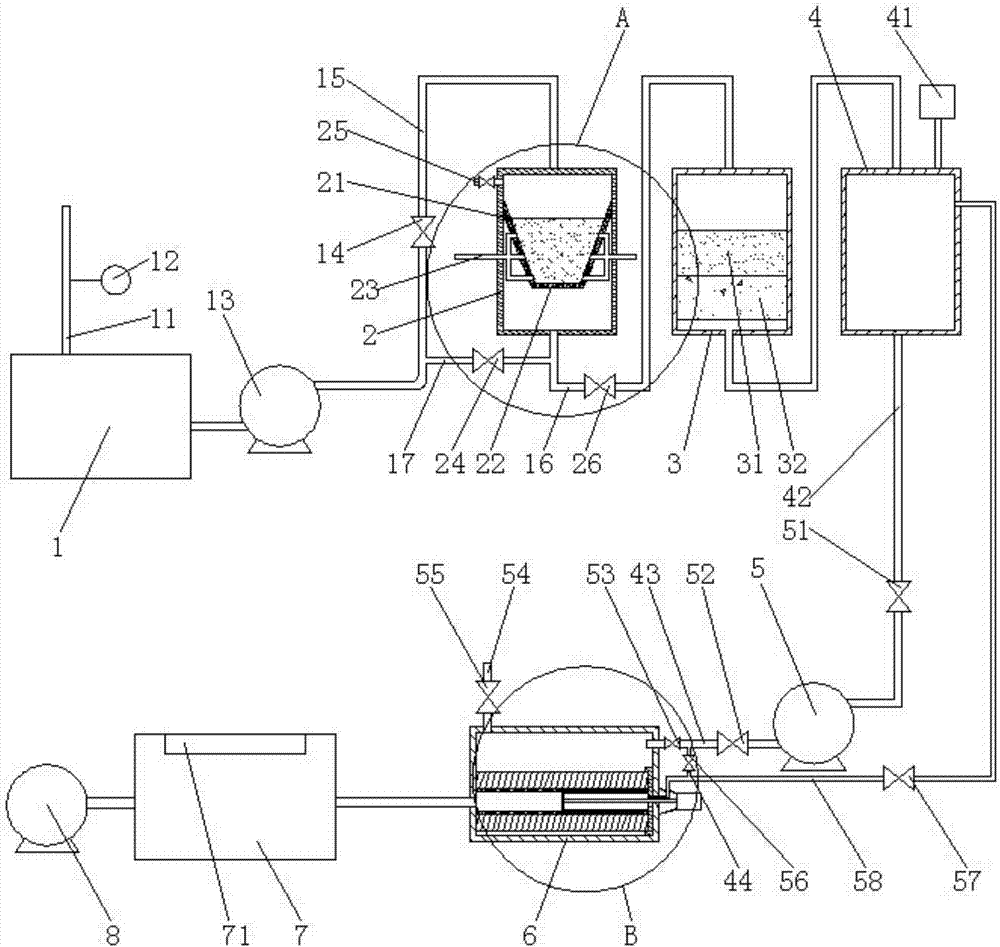

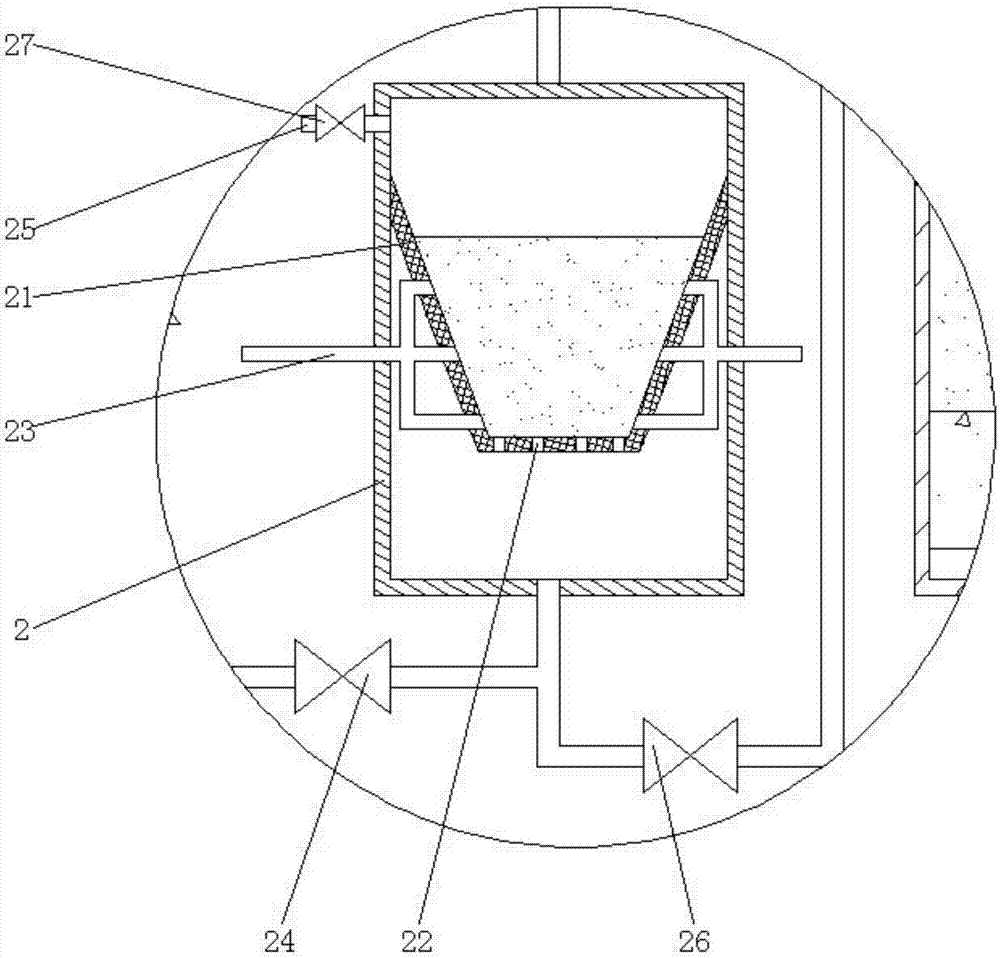

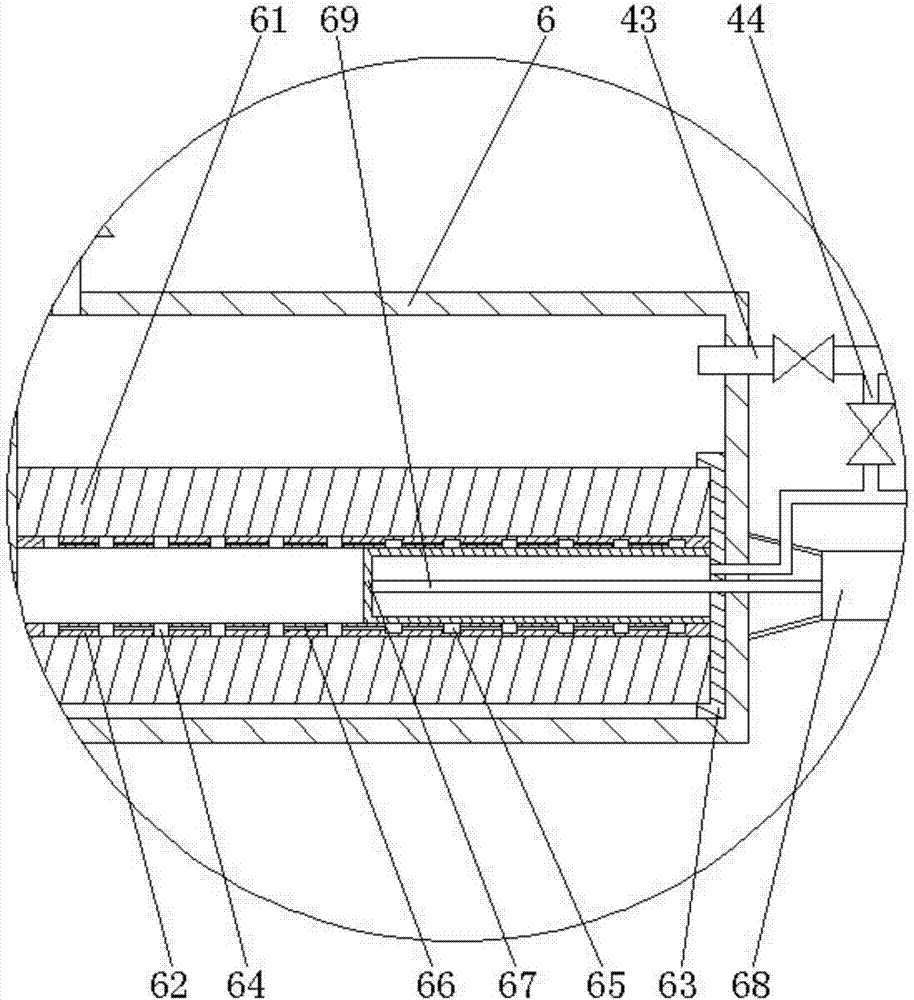

[0018] Such as Figure 1 ~ Figure 3 As shown, the pure water manufacturing equipment includes raw water tank 1, primary pressure pump 13, quartz sand filter 2, activated carbon filter 3, precision filter 4, secondary pressure pump 5, and reverse osmosis device 6 connected sequentially through pipelines. , a clean water tank 7 and a three-stage pressure pump 8, the inside of the quartz sand filter 2 is provided with a tapered storage basin 21 whose diameter gradually decreases from top to bottom, the upper end of the storage basin 21 is open, and the bottom of the storage basin 21 is provided with multiple A water outlet hole 22, the conical surface around the storage basin 21 is connected to the air intake pipe 23, the quantity of the air intake pipe 23 is two, symmetrically arranged on the conical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com