Homogenizing annealing thermal treatment technology for A390 aluminum alloy cast ingot

An aluminum alloy ingot, annealing heat treatment technology, applied in the field of metal material heat treatment, can solve the problems of poor eutectic silicon morphology, poor processing performance, and high alloy hardness, and achieve the elimination of intragranular segregation, improvement of processing performance, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

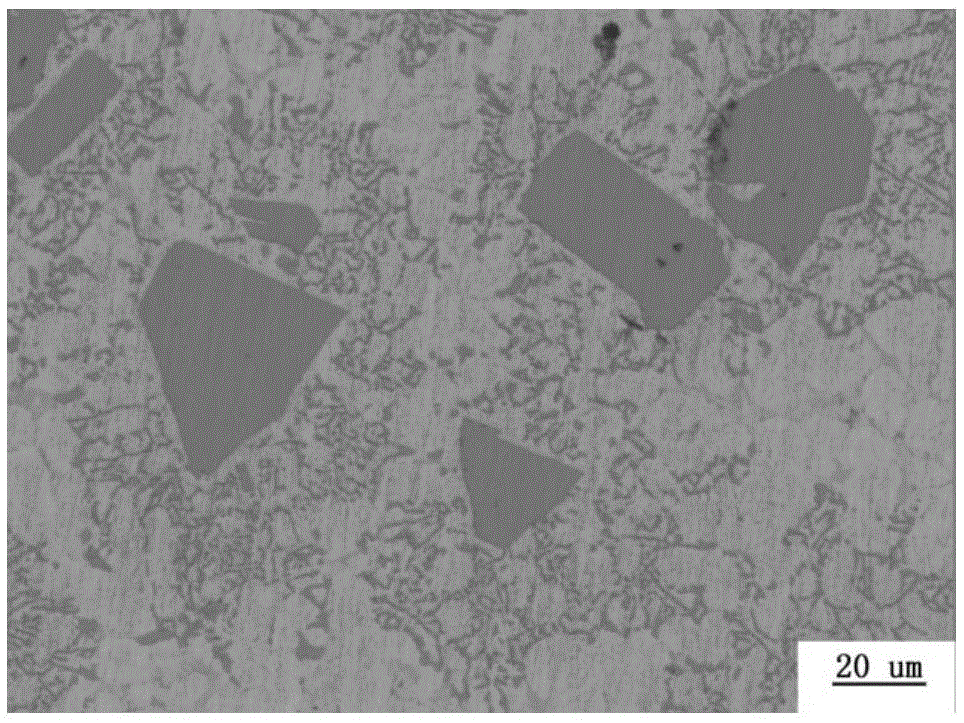

[0024] The A390 aluminum alloy ingot obtained by electromagnetic stirring-semi-continuous casting technology was put into a resistance furnace, the temperature was raised to 400°C with the furnace, and kept for 2 hours.

Embodiment 2

[0026] The A390 aluminum alloy ingot obtained by electromagnetic stirring-semi-continuous casting technology was put into a resistance furnace, and the temperature was raised to 450°C with the furnace, and kept for 4 hours.

Embodiment 3

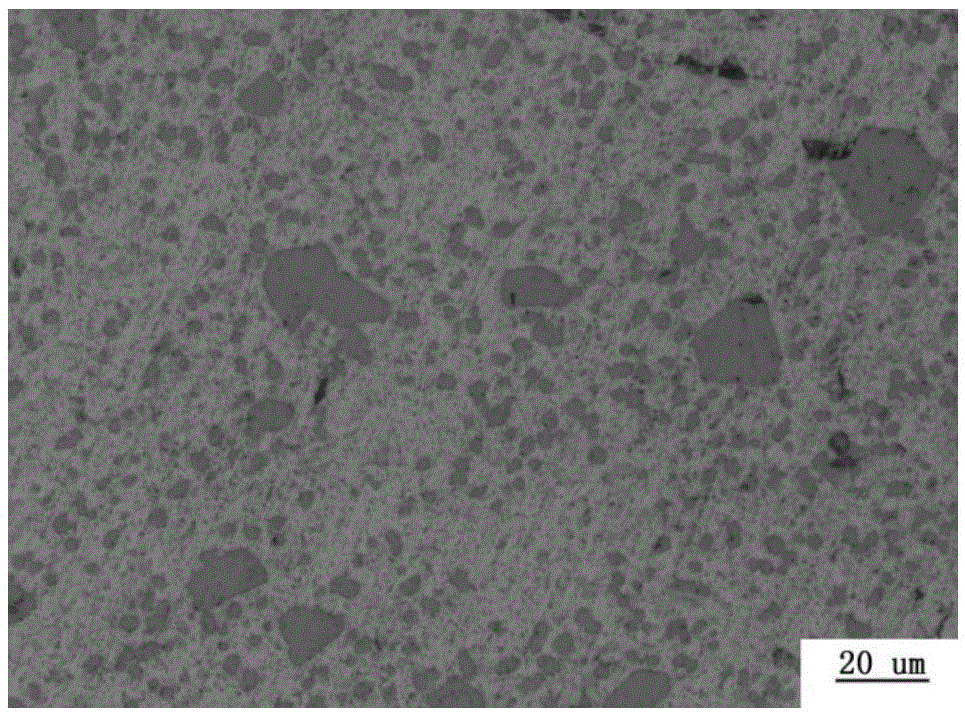

[0028] The A390 aluminum alloy ingot obtained by electromagnetic stirring-semi-continuous casting technology was put into a resistance furnace, and the temperature was raised to 480°C with the furnace, and kept for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com