A kind of support method of semi-closed reinforced concrete segment in deep coal mine

A reinforced concrete pipe and semi-closed technology, which is applied in the direction of earth drilling, mining equipment, shaft lining, etc., can solve the problems of high repair rate and difficult roadway support, and achieve long-term stability, avoid repeated repairs, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

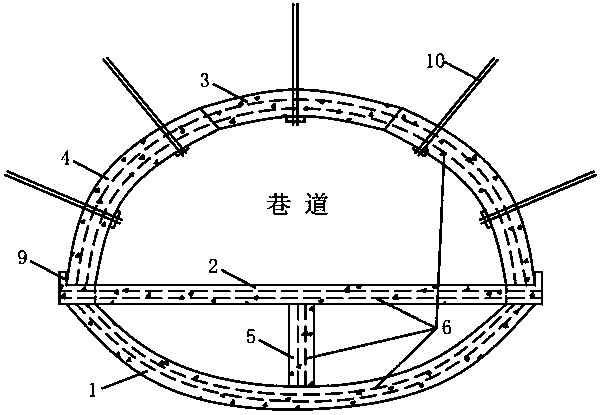

[0025] (1) Excavating coal lanes. Excavation is formed according to the design gross cross-section size, and the shape of the wellbore cross-section is horseshoe-shaped. Try to make the surface of the roadway as flat and smooth as possible, and avoid unevenness, so as to create good conditions for the installation of semi-closed prefabricated reinforced concrete segment support components.

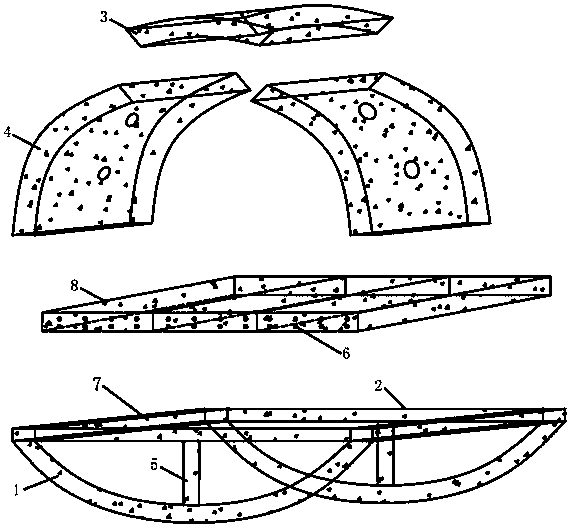

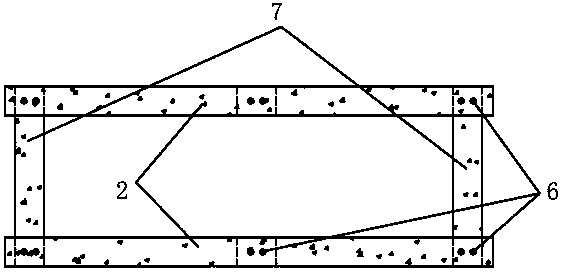

[0026] (2) Splicing of reinforced concrete segments. After the roadway is excavated, the anti-arch (1) and column (5) are first laid, the beam (2) and the axial beam (7) are erected, and then the prefabricated reinforced concrete cover plate (8) is laid, and after the cover plate is laid, erect Two gangs of prefabricated reinforced concrete segments (4) and a roof prefabricated concrete segment (3).

[0027] (3) Lag grouting reinforcement. After the prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com