Preparation and evaluation method of hydrophobic performance of a kind of hydrophobic coating

A water coating and coating technology, applied in the field of hydrophobic coating, can solve the problems of only qualitative analysis, unable to meet the working conditions of parts, unsuitable and other problems, and achieve the effect of good application condition, feasible process and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

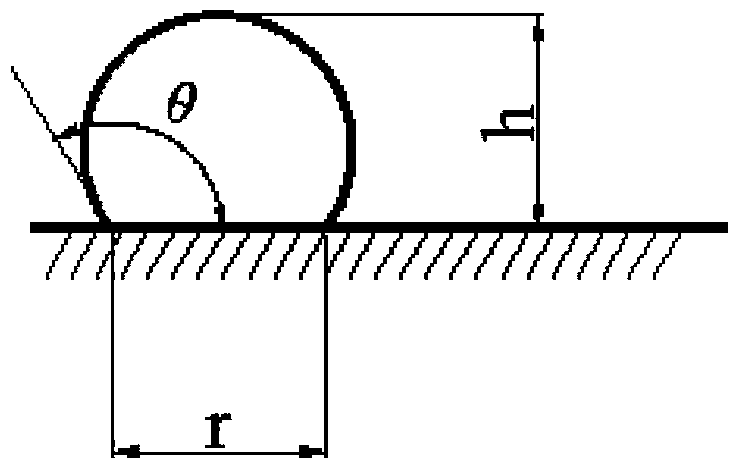

[0039] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0040] 1. Preparation of hydrophobic coating

[0041] Required materials: FR301B polytetrafluoroethylene concentrated dispersion (produced in Shanghai),

[0042] FR463 polyperfluoroethylene propylene concentrated dispersion (produced in Shanghai),

[0043] Chromic anhydride CrO3, phosphoric acid H 3 PO4, distilled water H 2 o

[0044] Preparation conditions: spraying device with ventilation system, copper mesh (200 mesh)

[0045] Preparation and application of A primer

[0046] Preparation of A1 primer: The primer is prepared by mixing acid solution and FR301B polytetrafluoroethylene concentrated dispersion. The composition of the mixed acid solution is shown in Table 1. The composition of the primer is shown in Table 2.

[0047] The composition of table 1 mixed acid solution

[0048]

[0049] The composition of table 2 primer

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com