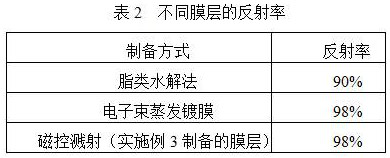

A high-reflection film layer for laser devices with high temperature resistance and strong acid corrosion resistance in exhaust gas and its preparation method

A laser device, high-reflection film technology, applied in coating, sputtering, metal material coating process, etc., can solve problems such as poor bonding force, difficult thickness control, etc., to achieve stable performance, reduce stress concentration, and combine strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

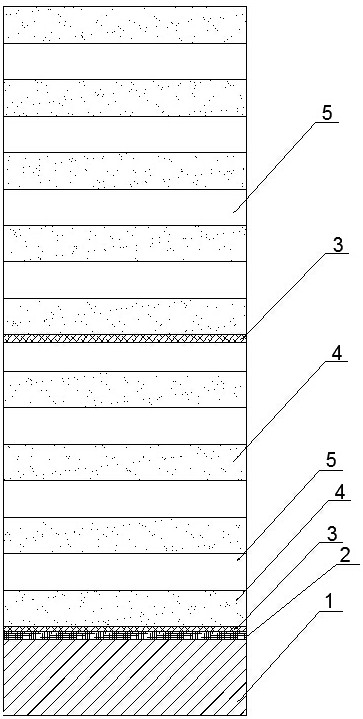

[0043] The specific steps of the above-mentioned method for preparing a high-reflection film layer for laser devices resistant to high temperature and strong acid corrosion in exhaust gas are as follows:

[0044] 1) Substrate preparation: polishing the substrate;

[0045] 2) Ti film coating by magnetron sputtering: coating Ti film on the surface of Ti alloy substrate;

[0046] 3) Ag coating: Coating a reflective Ag coating on the Ti coating;

[0047] 4) TiO plating 2 Membrane: TiO coating with high transmission film on Ag film 2 membrane;

[0048] 5) SiO plating 2 Membrane: on TiO 2 Coated with high reflective film SiO on the film 2 membrane;

[0049] 6) Alternate coating: TiO 2 film with SiO 2 The membranes were alternated for 8 cycles, and at the end of the 4th cycle, the SiO 2 Coating Ag film on the film, then coating TiO on the Ag film 2 film, TiO 2 Coated SiO on film 2 Membrane... Alternate the remaining 4 cycles, with the final layer of SiO 2 TiO 2 membran...

Embodiment 1

[0063] A high-reflection film layer for laser devices with high temperature resistance and strong acid corrosion resistance in exhaust gas, including a substrate, a Ti film is coated on the substrate, an Ag film is coated on the Ti film, and TiO is coated on the Ag film 2 film, TiO 2 Coated SiO on film 2 film, SiO 2 TiO coating on film 2 film, TiO 2 film with SiO 2 The membranes were alternated for 4 cycles, and at the end of the 4th cycle, the SiO 2 Coating Ag film on the film, then coating TiO on the Ag film 2 film, TiO 2 Coated SiO on film 2 Membrane... 4 more cycles alternated, with the final layer of SiO 2 TiO 2 film, and prepare a high reflective film layer for laser devices.

[0064] The matrix is Ti-6Al-4V alloy.

[0065] The thickness of the Ti film is 20nm, Ag film, TiO 2 film and SiO 2 The film thicknesses were all 500 nm.

[0066] The thickness of the substrate is 500 μm.

[0067] The specific steps of the above-mentioned method for preparing a hig...

Embodiment 2

[0078] A high-reflection film layer for laser devices with high temperature resistance and strong acid corrosion resistance in exhaust gas, including a substrate, a Ti film is coated on the substrate, an Ag film is coated on the Ti film, and TiO is coated on the Ag film 2 film, TiO 2 Coated SiO on film 2 film, SiO 2 TiO coating on film 2 film, TiO 2 film with SiO 2 The membranes were alternated for 4 cycles, and at the end of the 4th cycle, the SiO 2 Coating Ag film on the film, then coating TiO on the Ag film 2 film, TiO 2 Coated SiO on film 2 Membrane... 4 more cycles alternated, with the final layer of SiO 2 TiO 2 film, and prepare a high reflective film layer for laser devices.

[0079] The matrix is Ti-6Al-4V alloy.

[0080] The thickness of the Ti film is 22nm, the thickness of the Ag film is 620nm, and the TiO 2 The thickness of the film is 550nm, SiO 2 The thickness of the film was 600 nm.

[0081] The thickness of the substrate is 550 μm.

[0082] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com