A method of manufacturing a return plate of a plunger pump

A manufacturing method and a return plate technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low material utilization rate, low production efficiency, complicated process, etc., achieve simple process, increase production efficiency, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0022] A method for manufacturing a return plate of a plunger pump, comprising the following steps:

[0023] Mixing: Weigh each raw material according to the weight percentage of each component in Table 1. Iron powder is reduced iron powder; add spindle oil to iron powder, mix for 20-200 minutes to form oil-containing iron powder, and then mix oil-containing iron powder, stearic acid Zinc and graphite are added to the mixer and mixed. The grade of graphite is 299, and the copper powder is electrolytic copper powder. After mixing evenly, take it out to obtain the mixed powder;

[0024] Press the green compact: Install the return disc mold on the press, put the mixed powder into the cavity of the mold, and press the mixed powder into a return disc compact with a compact density of 6.6-6.9g / cm 3 ;

[0025] Copper infiltrating sintering: Place the copper infiltrating sheet above the compact of the return plate, and carry out copper infiltrating sintering in a protective atmospher...

Embodiment 3-5

[0030] The difference from Example 1-2 is that in the mixing step, the grade of graphite is 399; the iron powder is atomized iron powder. The manufactured return disk was tested for performance, and the results are shown in Table 2.

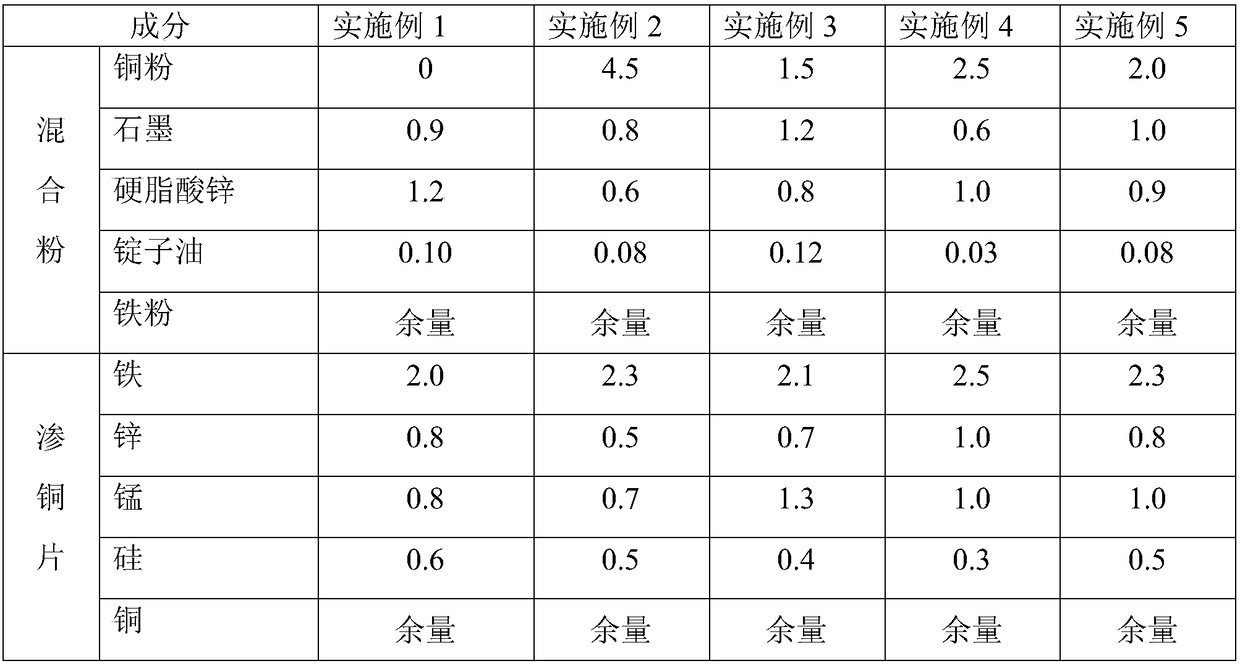

[0031] Table 1 return plate embodiment 1-5 proportioning table (wt%)

[0032]

[0033] Table 2 The performance test results of the return disk prepared in Example 1-5

[0034] performance

[0035] The running time of the installation test of the return disk made by the present invention is more than 300 hours, which fully meets the working conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com