Preparation method for solar cell with integrated diode

A technology of integrating diodes and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high turn-on voltage of bypass diodes, unreasonable preparation process, edge reverse leakage, etc., and achieve forward voltage drop and optimization quality, the effect of small turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

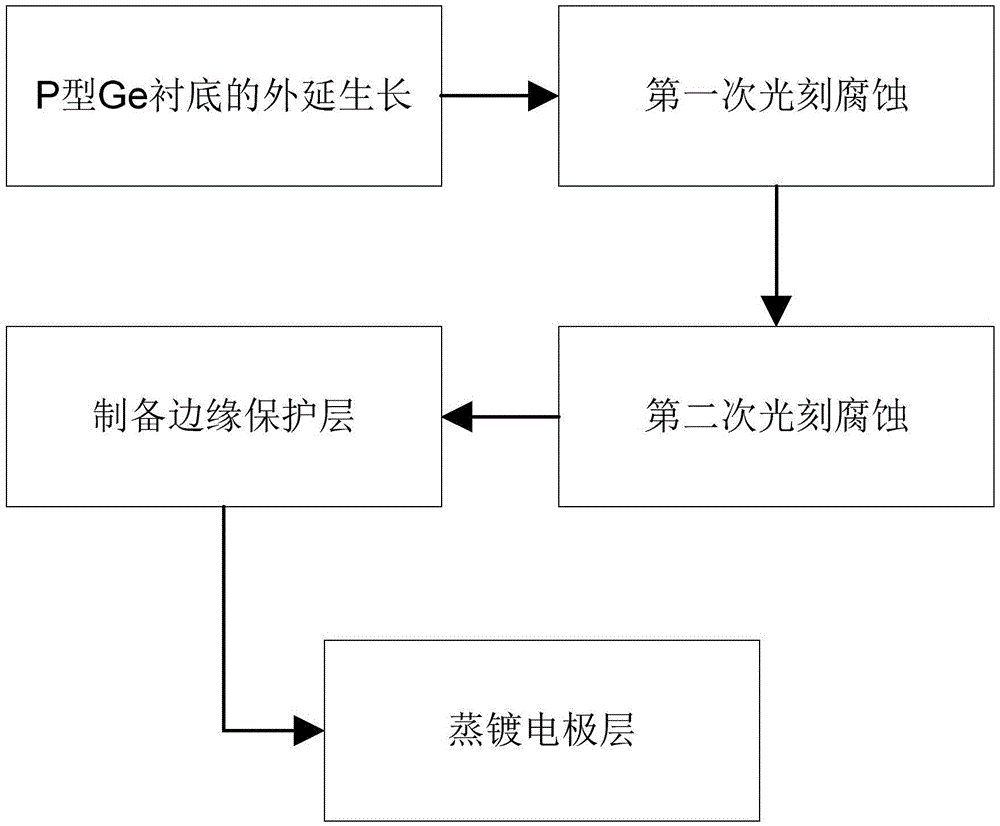

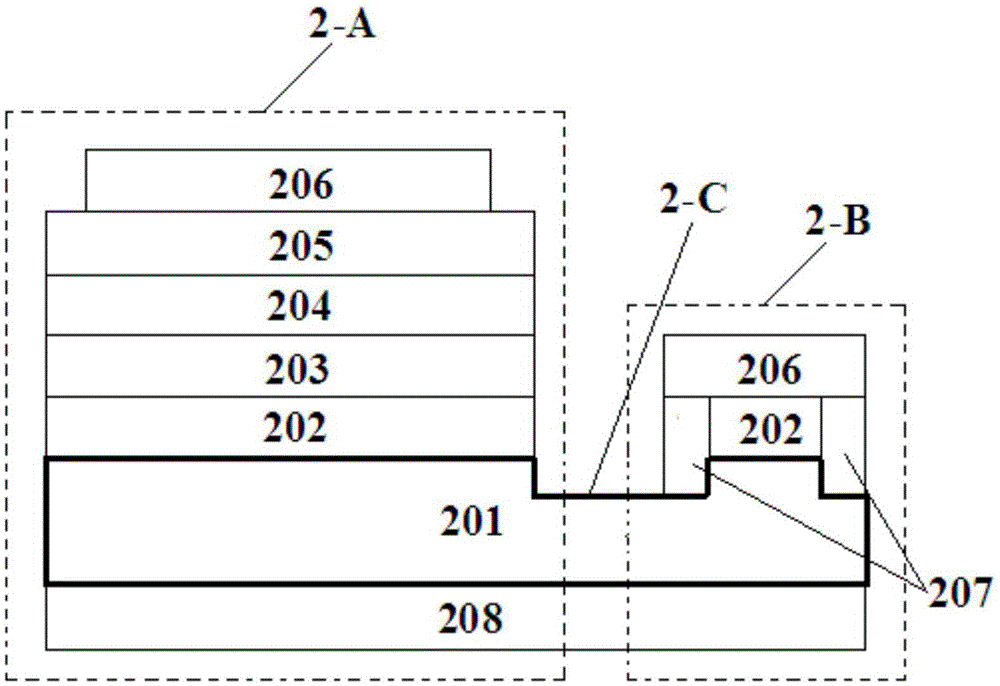

[0029] Such as Figure 1-2 Shown, a kind of preparation method of the solar cell with integrated diode comprises the following steps:

[0030] (a) Epitaxial growth of the P-type Ge substrate 201, the steps of which are: sequentially epitaxially growing Ge sub-cells, GaAs sub-cells 204 and GaInP sub-cells 205 on the P-type Ge substrate 201;

[0031] (b) Photoetching for the first time, the steps are: first determine the pattern to be etched of the isolation groove 2-C and the bypass diode 2-B through the photolithography plate and perform photoetching, and then remove the pattern to be etched by wet etching. Etching the GaInP sub-cell 205 and the GaAs sub-cell 204 within the pattern;

[0032] (c) second photolithographic etching, the steps of which are: first determine the pattern to be etched of the isolation groove 2-C through a photolithog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com